Passivation skin film agent special for aluminum product and preparation method of passivation skin film agent

A film agent, aluminum product technology, applied in the direction of metal material coating technology, etc., can solve the problems of skin allergies, genetic damage, toxicity, etc., to increase adhesion and corrosion resistance, improve anti-oxidation effect, good anti-corrosion The effect of the oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

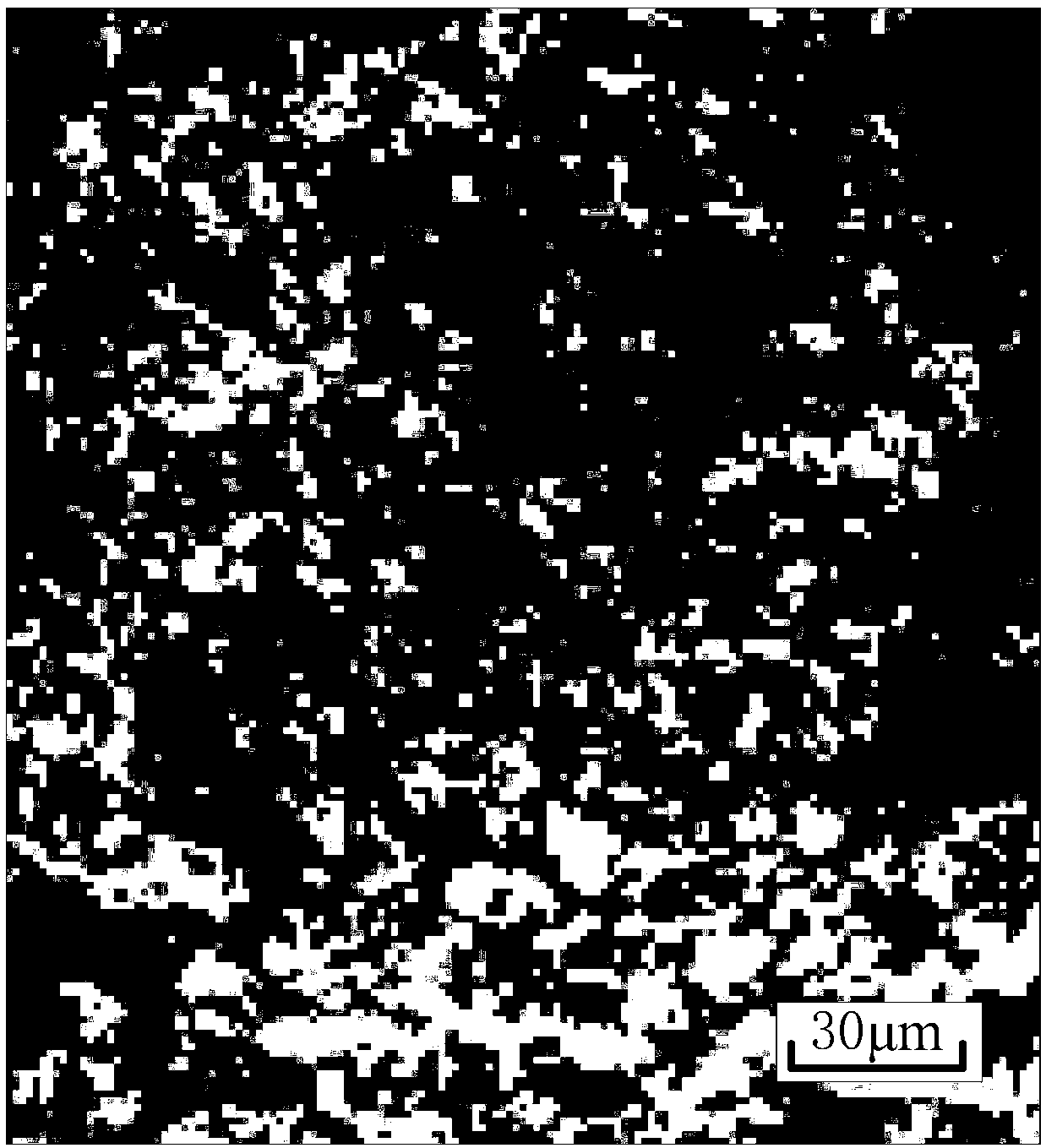

Image

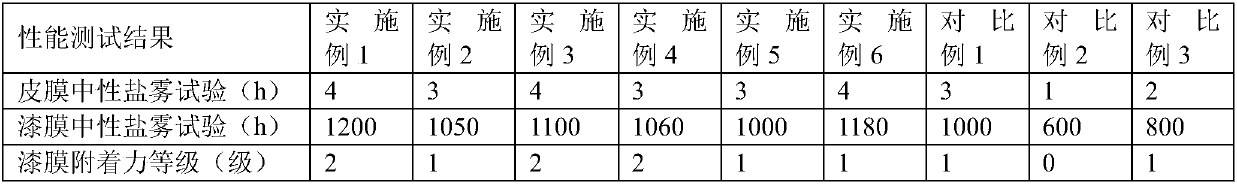

Examples

Embodiment 1

[0028] S1: Add 15kg of fluorozirconic acid, 5kg of vinyltrimethoxysilane, and 9kg of sodium phytate into 200kg of purified water. After the solid matter is completely dissolved, slowly add 2,3,5,6-tetramethyl to the mixture Base-1,4-dioxacyclo-2,5-diol 1.5kg, polyvinyl alcohol 0.75kg, polyethylene glycol 0.75kg, the addition time is 15min, stir evenly until the solid matter is completely dissolved, wherein, the system temperature 44°C;

[0029] S2: Take 15kg of epoxy resin and add it to the mixed solution obtained in S1, and stir evenly for 25 minutes until the solid matter is completely dissolved, wherein the system temperature is 55°C;

[0030] S3: Add 5 kg of titanium dioxide and 13 kg of ethylenediaminetetraacetic acid into the mixed solution obtained in S2, and stir evenly for 25 minutes until the solid matter is completely dissolved to prepare a special passivation film agent for aluminum products, wherein the system temperature is 34°C.

Embodiment 2

[0032] S1: Take 10kg of fluorozirconic acid, 4kg of 3-aminopropyl trimethoxy silicon, and 6kg of potassium phytate and add it to 200kg of pure water. After the solid matter is completely dissolved, slowly add 2,3,5,6 -Tetramethyl-1,4-dioxacyclo-2,5-diol 2kg, polyvinyl alcohol 1kg, polyethylene glycol 0.5kg, adding time is 15min, stirring evenly until the solid matter is completely dissolved, wherein, the system The temperature is 46°C;

[0033] S2: Take 10kg of acrylic resin and add it into the mixed solution obtained in S1, and stir evenly for 20 minutes until the solid matter is completely dissolved, wherein the system temperature is 51°C;

[0034] S3: Add 4 kg of titanium dioxide and 14 kg of sodium ethylenediamine tetraacetate into the mixed solution obtained in S2, and stir evenly for 30 minutes until the solid matter is completely dissolved to prepare a special passivation film agent for aluminum products, wherein the system temperature is 31°C.

Embodiment 3

[0036] S1: Add 20kg of fluorozirconic acid, 4kg of vinyltrimethoxysilane, and 6kg of potassium phytate into 200kg of purified water. After the solid matter is completely dissolved, slowly add 2,3,5,6-tetramethyl to the mixture Diol-1,4-dioxacyclo-2,5-diol 2kg, polyvinyl alcohol 0.5kg, polyethylene glycol 1kg, adding time is 20min, stirring evenly until the solid matter is completely dissolved, wherein, the system temperature is 46 ℃; S2: Take 10kg of epoxy resin and add it to the mixed liquid obtained in S1, and stir evenly for 30 minutes until the solid matter is completely dissolved, and the system temperature is 51°C;

[0037] S3: Add 4 kg of titanium dioxide and 14 kg of sodium ethylenediamine tetraacetate into the mixed solution obtained in S2, and stir evenly for 20 minutes until the solid matter is completely dissolved to prepare a special passivation coating agent for aluminum products, wherein the system temperature is 37°C.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap