Multi-quantum well layer growing method of micro LED

A multi-quantum well layer and growth method technology, which is applied in the field of microLED multi-quantum well layer growth, can solve the problems of poor crystallization quality and poor electrical parameters of the quantum well layer structure, so as to improve antistatic ability and leakage performance, improve Effects of crystal quality and dislocation density reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

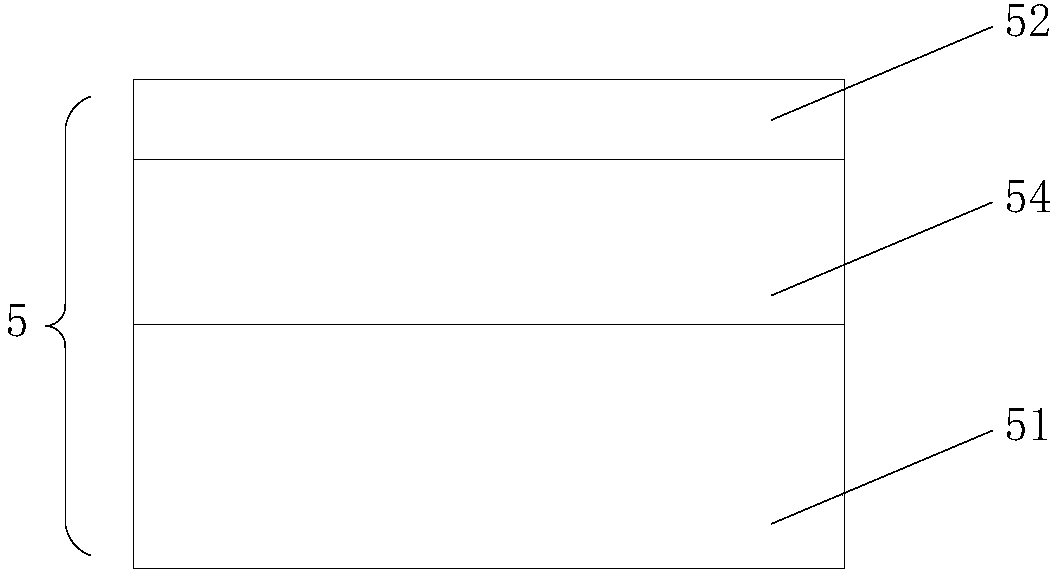

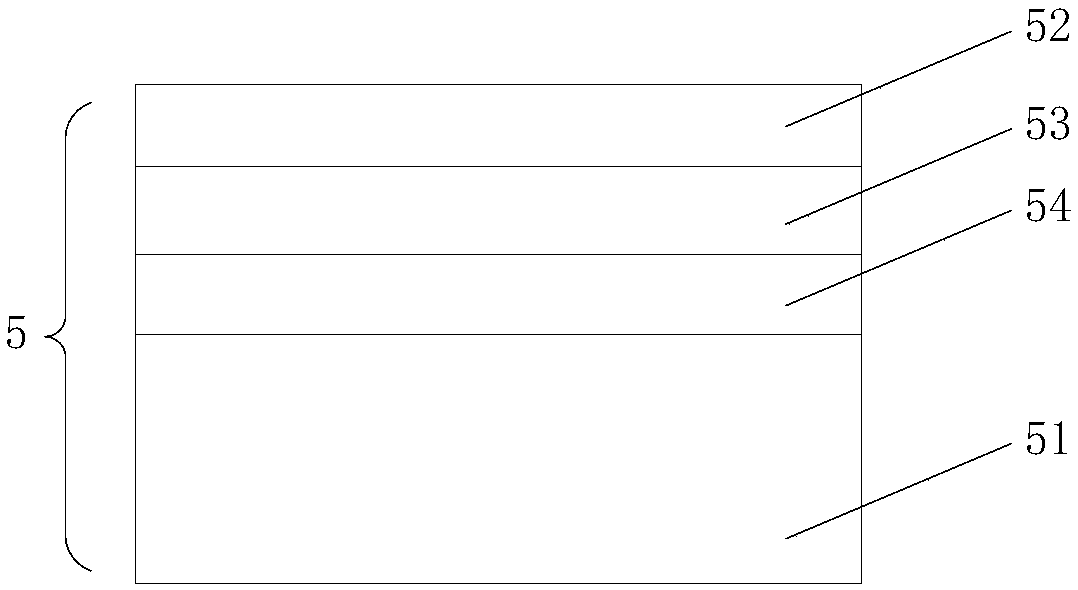

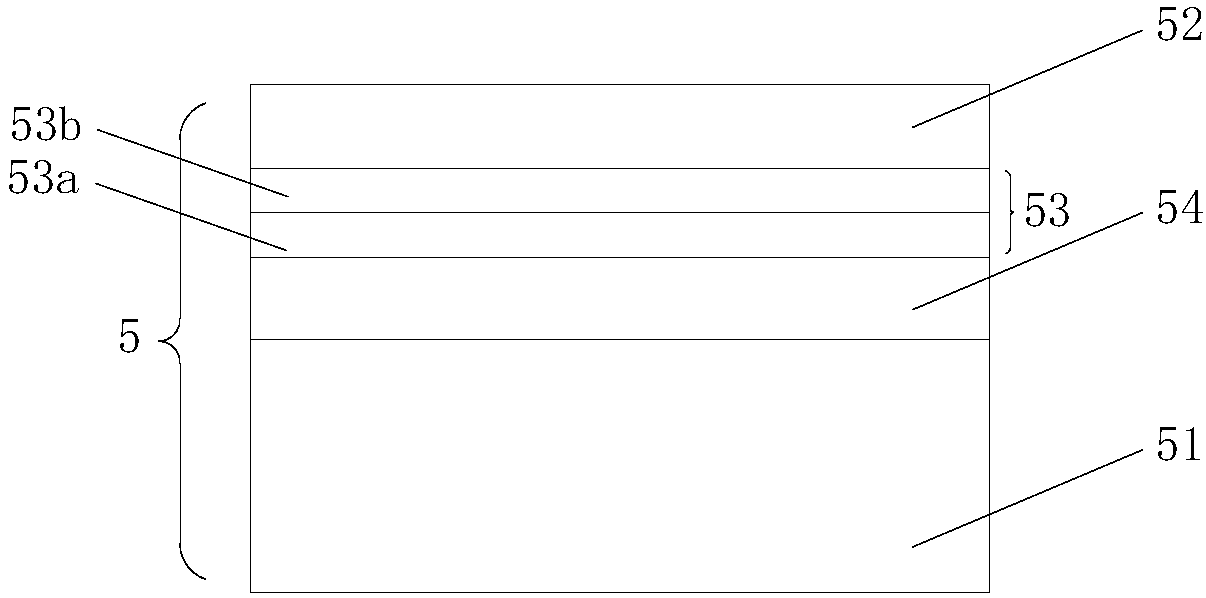

[0022] The present invention provides a microLED multi-quantum well layer growth method, see figure 1 , the multi-quantum well layer 5 includes GaN barrier layer 51 and In x Ga 1-x N well layer 52, 0x Ga 1-x No hydrogen gas is injected into the N well layer 52 during the process.

[0023] Introducing hydrogen gas during the formation of the microLED epitaxial structure can effectively improve the crystal quality of GaN, but when growing multiple quantum well layers, due to the In x Ga 1-x The N well layer 52 contains In components, and the introduction of hydrogen will destroy the In structure, thereby reducing the luminous efficiency. In the prior art, when growing the GaN barrier layer 51, the In x Ga 1-x In the same atmosphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com