Preparation method of nano-crystalline cellulose aerogel and thermal insulation material

A technology of nanocellulose and cellulose, applied in the field of thermal insulation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

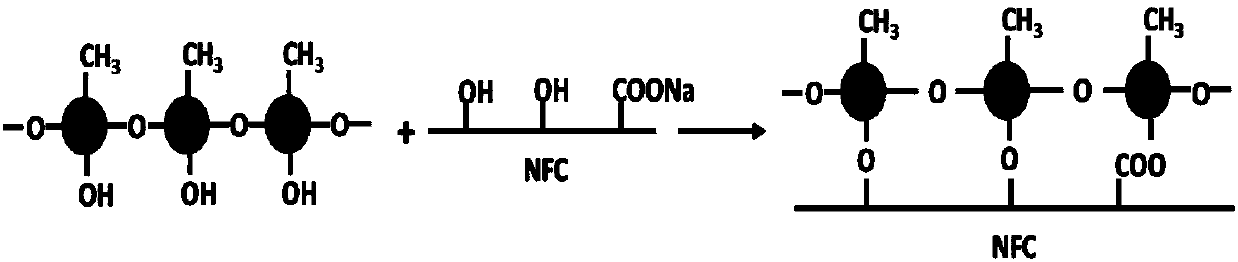

[0031] The invention provides a kind of preparation method of nano-cellulose airgel, comprising the following steps:

[0032] Pretreating the cellulose pulp with tetramethylpiperidine nitrogen oxide and bromide to obtain a cellulose mixture;

[0033] In the presence of lye, the cellulose mixture and the strong oxide are oxidized to obtain an oxidized product;

[0034] Washing the oxidized product with water after ultrasonication to obtain a nanocellulose suspension;

[0035] mixing the nanocellulose suspension with the acidified alkylsilsesquioxane to obtain a mixed solution;

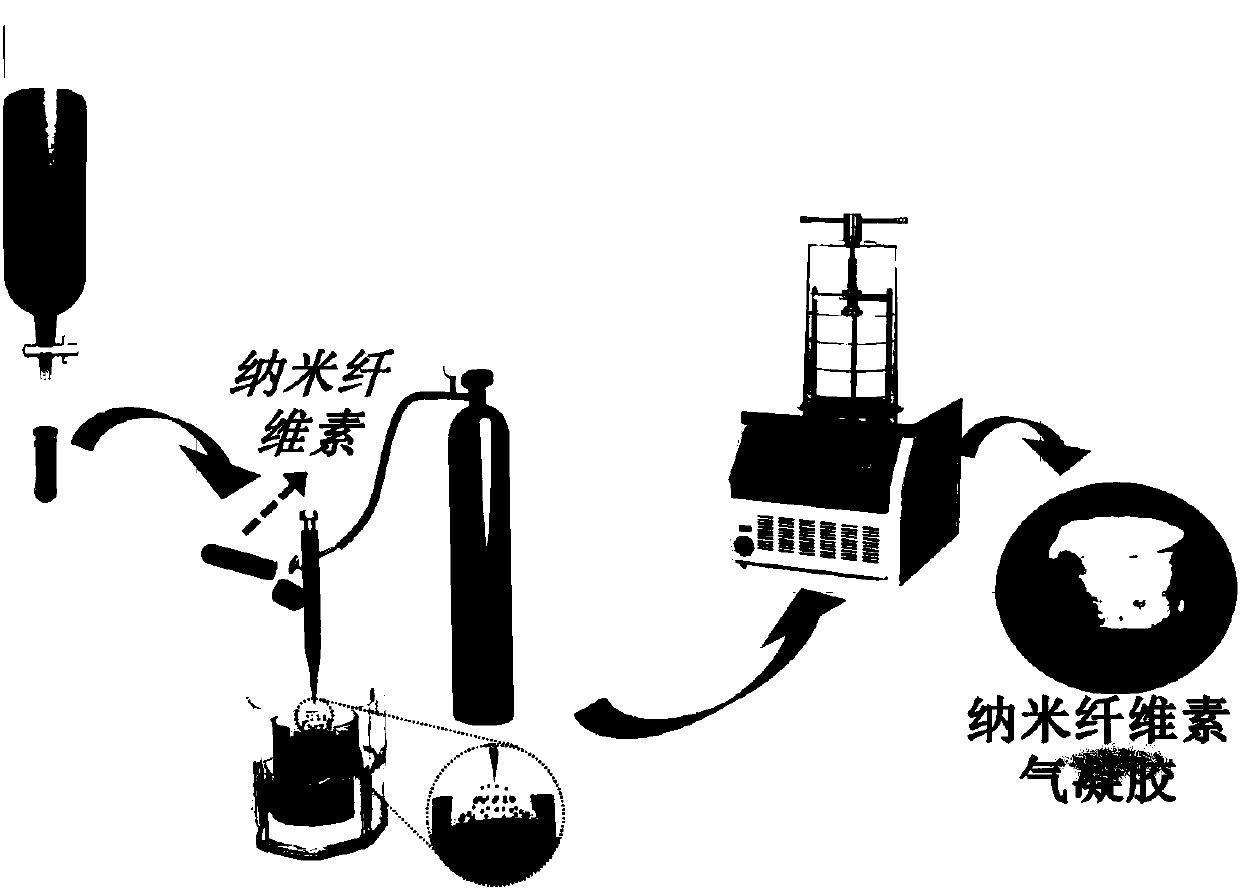

[0036] The mixed liquid is atomized and freeze-dried to obtain nanocellulose airgel.

[0037] The preparation method provided by the invention can realize the uniform methylation of the nanocellulose molecules, and inhibit the destruction of the nanocellulose airgel structure skeleton by the growth of ice crystals in the freezing process. This method has the advantages of low preparation cost, simple...

Embodiment 1

[0053] Take 2.0g of wood pulp fiber and slowly pour it into the conical flask, then add 0.01g of tetramethylpiperidine nitrogen oxide and 0.05g of sodium bromide into the conical flask, mix and stir evenly, then add 0.5g The mass fraction is 10% sodium hypochlorite solution, then the two are continuously and slowly stirred, during the stirring period, the pH value of the monitoring mixture system is maintained at 10 unchanged. The reaction was terminated when the pH value of the mixture no longer decreased. The reacted mixed solution was subjected to ultrasonic treatment for 30 min at an ultrasonic frequency of 15 KHz, and then washed three times with water to obtain nanocellulose suspension. Mix the prepared nanocellulose suspension with the acidified methyltrimethoxysilane according to the mass ratio of 1:0.05, pour it into the atomizer, and atomize the nanocellulose into the tank filled with liquid nitrogen by air pressure. in a copper can. Finally, the copper can was pu...

Embodiment 2

[0060] Take 3.0g of wood pulp fiber and slowly pour it into the conical flask, then add 0.05g of tetramethylpiperidine nitrogen oxide and 0.3g of sodium bromide in the conical flask, mix and stir evenly, then add 0.5g 10% sodium hypochlorite solution, then the two are continuously stirred slowly, during the stirring period, monitor the pH value of the mixture system, adjust the pH value of the mixed reaction system by dripping 0.5mol / L sodium hydroxide solution and maintain it at 10 . The reaction was terminated when the pH value of the mixture no longer decreased. The reacted mixed solution was subjected to ultrasonic treatment for 30 min, and the ultrasonic frequency was 15KHz. Then rinse with water three times to obtain a nanocellulose suspension; mix the obtained nanocellulose suspension with acidified methyltrimethoxysilane according to a mass ratio of 1:0.1, pour it into an atomizer, and pass Air pressure atomizes the nanocellulose into a copper tank filled with liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Hydrophobic angle | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com