Chip sintered product, sub unit, IGBT packaging module and preparation method

A technology for encapsulating modules and sintered products, which is applied in the fields of IGBT packaged modules and their preparation, chip sintered products, subunits, press-fit IGBT packaged modules and their preparations, and can solve the problems of reducing thermal resistance, poor thermal interface layer compactness, shear Low shear strength and other problems, to achieve the effect of reducing thermal resistance, increasing shear strength, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

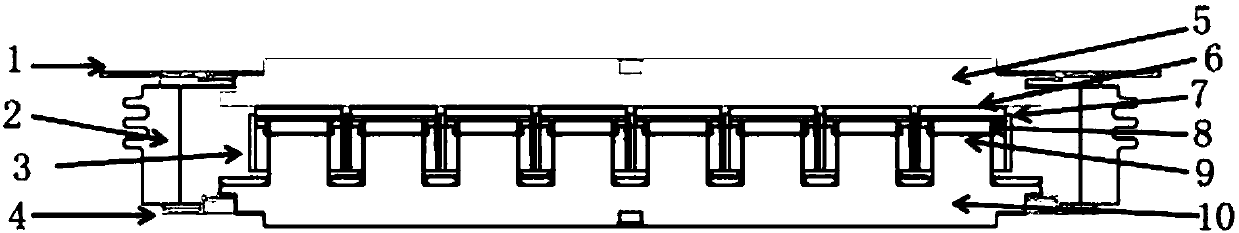

[0060] In the preparation process of the IGBT package module, the pressure sintering equipment of the model Auto-F-XL-HC manufactured by boschman can be used in the pressure sintering process.

[0061] Chip sintered products:

Embodiment 1

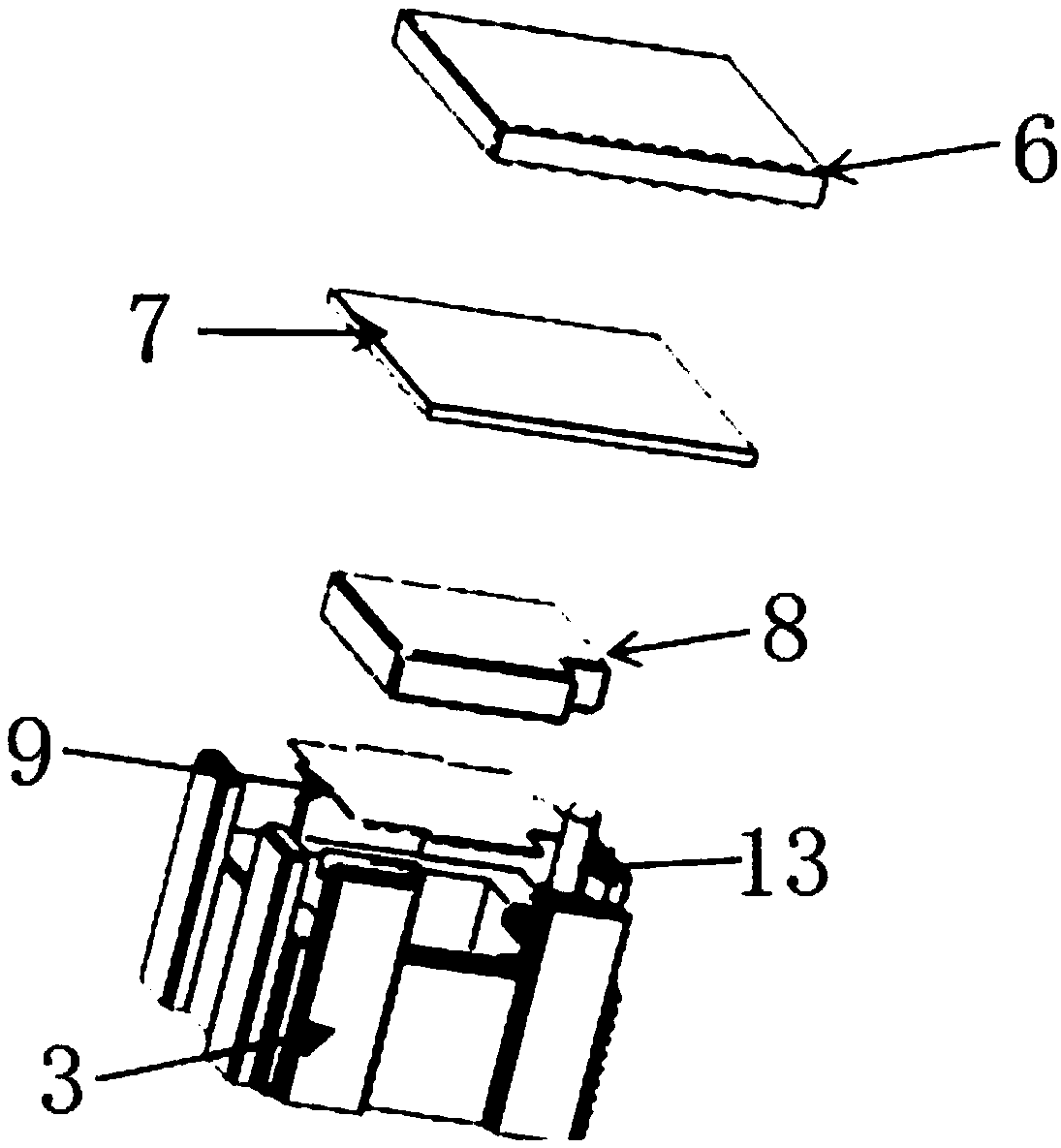

[0063] This embodiment provides a chip sintered product, including a first molybdenum sheet and a second molybdenum sheet and a chip 7 arranged between them, at least one of the first molybdenum sheet and the second molybdenum sheet is a prefabricated molybdenum sheet The prefabricated molybdenum sheet is a molybdenum sheet with a prefabricated nano-silver film 14 on the surface, and at least one side of the chip 7 is in contact with the prefabricated nano-silver film 14 .

[0064] In the present embodiment, the first molybdenum sheet is a prefabricated molybdenum sheet, which is obtained by pressing the prefabricated nano-silver film 14 on the upper molybdenum sheet 6, and the second molybdenum sheet is a non-prefabricated molybdenum sheet, that is, the lower molybdenum sheet 8; In another embodiment, both the first molybdenum sheet and the second molybdenum sheet are prefabricated molybdenum sheets.

[0065] In the above chip sintering products, the use of prefabricated nano...

Embodiment 2

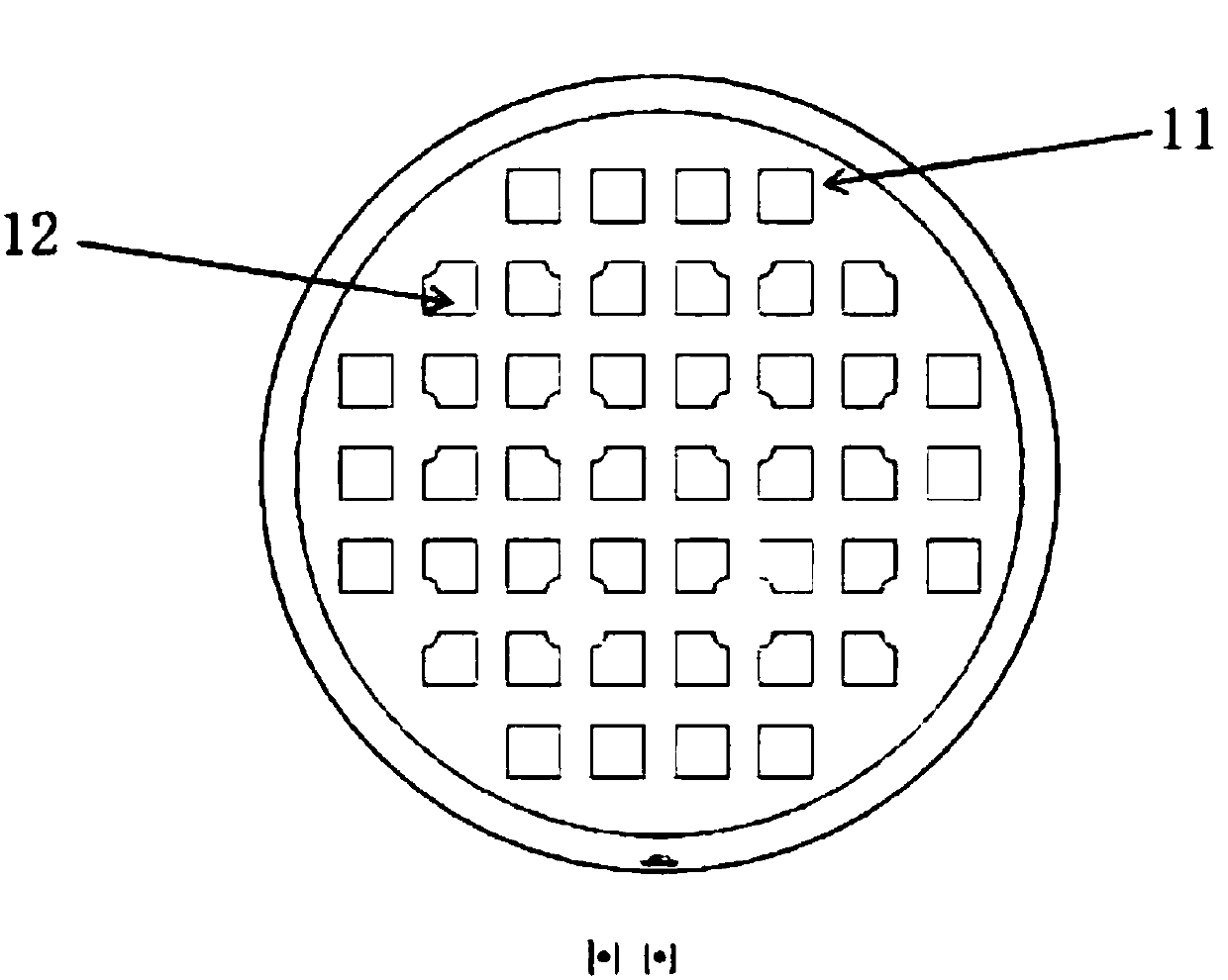

[0076] This embodiment provides a chip subunit 15, such as image 3 As shown, including the chip sintered product in embodiment 1;

[0077] The metal support sheet is in contact with the lower molybdenum sheet 8 and is used to support the chip sintered product; in the present embodiment, the metal support sheet is a silver sheet 9;

[0078] The subunit frame 3 has an opening at one end, and a support unit suitable for supporting the metal support sheet is arranged in it; in this embodiment, the support unit can specifically be provided with a groove on the inner peripheral wall of the subunit frame 3 close to the opening, The groove is suitable for the metal support sheet to be stuck on it through the opening, and the subunit frame 3 is made of PEAK material; The shaft extends perpendicular to the inner wall, and the metal support sheet can be placed on the support shaft;

[0079] A connection unit, one end of which is in contact with the grid on the chip, to ensure its elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com