Method for preparing high silicon steel thin strip through powder hot pressing sintering

A hot-pressing sintering, high-silicon steel technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of high energy consumption and cost, complex process, unsatisfactory scale and output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Mix -100 mesh reduced Fe powder with Fe-70% Si high-purity powder with a particle size of ≤6 μm in a ratio of 90.43:9.57 to form Fe-6.7% Si mixed powder. When mixing, add 0.6% paraffin micropowder and 0.1% engine oil of the total amount of raw materials. Dehydrated alcohol is added according to the amount of 200ml / ton. The above powders were mixed for 4 h using a V-shaped blender.

[0047] A square compact was prepared by compression molding, with a surface pressure of 600MPa, a compact size of 100×100×40mm, and a compact density of 6.36g / cm 3 .

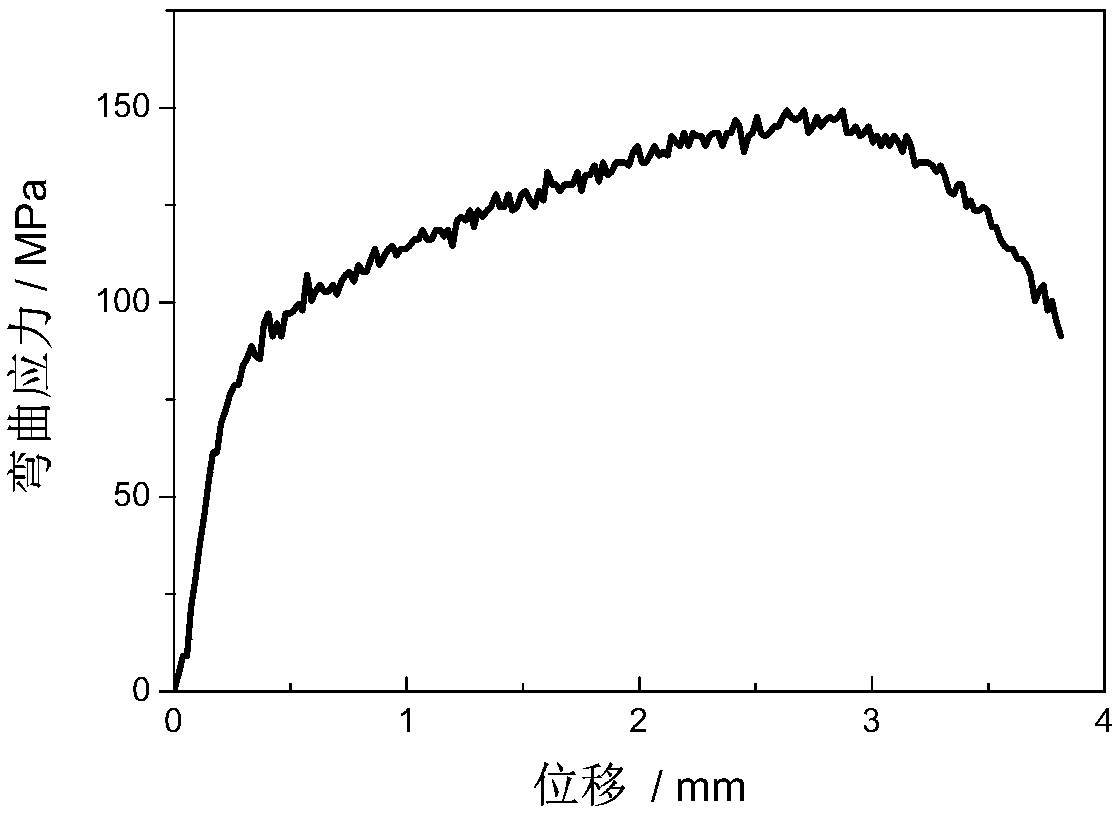

[0048] 100MPa uniaxial pressure hot pressing sintering, hot pressing sintering at 920°C for 2 hours, the thickness of the billet is about 36mm, and the density reaches 6.68g / cm 3 . Three-point bending tests exhibit plasticity, see figure 1 , the bending strength reaches 147MPa.

[0049] The above-mentioned hot-pressed sintered plate is cold-rolled-sintered and gradually thinned. The specific pressing-annealing system is...

Embodiment 2

[0053] Mix -100 mesh reduced Fe powder with Fe-50% Si high-purity powder with a particle size of ≤10 μm in a ratio of 91:9 to form Fe-4.5% Si mixed powder. When mixing, add 0.7% zinc stearate and 0.1% machine oil of the total amount of raw materials. Dehydrated alcohol is added according to the amount of 400ml / ton. The above powders were mixed for 6 h using a drum mixer.

[0054] A square compact was prepared by compression molding, with a surface pressure of 400MPa, a compact size of 300×300×60mm, and a compact density of 6.53g / cm 3 .

[0055] 160MPa uniaxial pressure hot pressing sintering, hot pressing sintering at 980°C for 0.5h, the thickness of the billet is about 54mm, and the density reaches 7.04g / cm 3 . The three-point bending test showed plasticity, and the bending strength reached 347MPa.

[0056] The above-mentioned hot-pressed sintered plate is cold-rolled-sintered and gradually thinned. The specific pressing-annealing system is: 54mm→36mm→36mm→24mm→17mm→12m...

Embodiment 3

[0061] Mix -100 mesh reduced Fe powder with Fe-60% Si high-purity powder with particle size ≤ 6 μm according to the ratio of 89.17:10.83 to form Fe-6.5% Si mixed powder. When mixing, add 0.4% paraffin micropowder, 0.2% methylcellulose, and 0.1% motor oil in the total amount of raw materials. Dehydrated alcohol is added according to the amount of 400ml / ton. The above powders were mixed for 6 h using a drum mixer.

[0062] A square compact was prepared by compression molding, with a surface pressure of 500MPa, a compact size of 120×120×50mm, and a compact density of 6.40g / cm 3 .

[0063] 120MPa uniaxial pressure hot pressing sintering, hot pressing sintering at 960°C for 1h, the thickness of the billet is about 46mm, and the density reaches 6.76g / cm 3 . The three-point bending test showed plasticity, and the bending strength reached 217MPa.

[0064] The above-mentioned hot-pressed sintered plate is cold-rolled-sintered and gradually thinned. The specific pressing-annealing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com