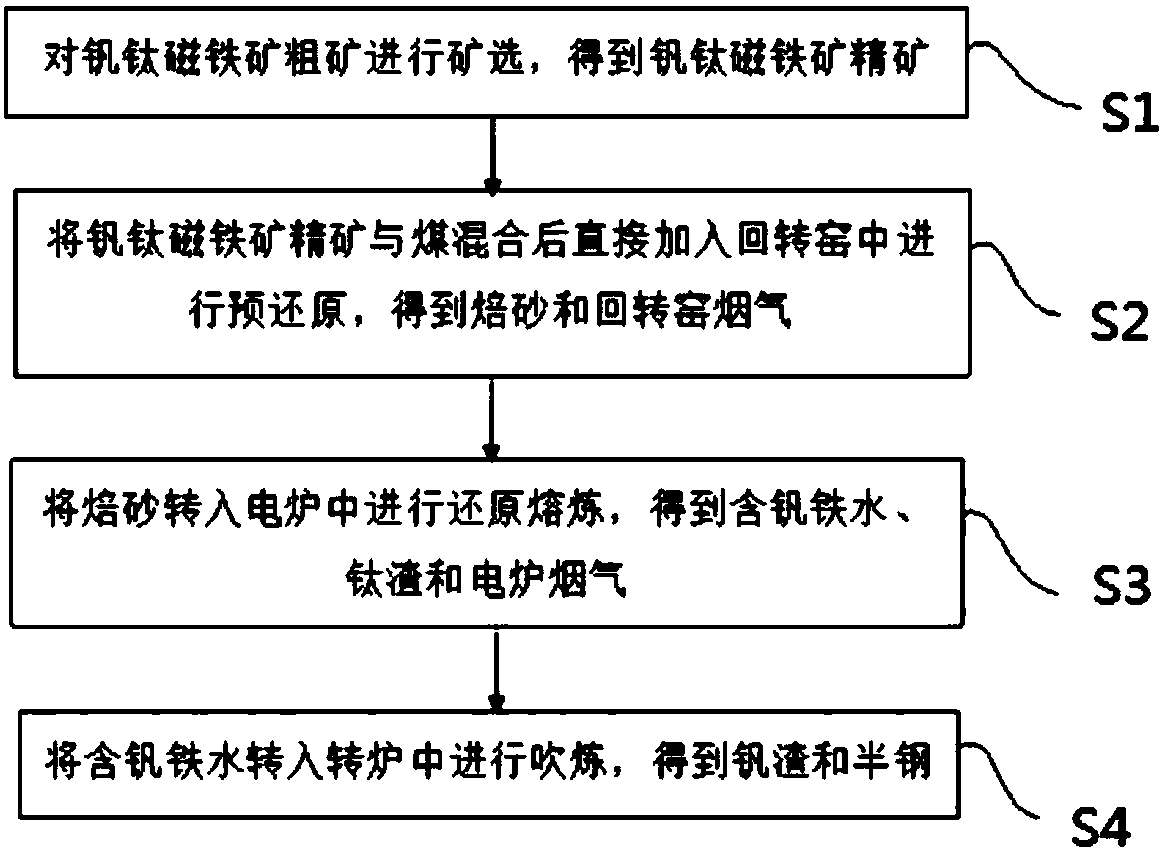

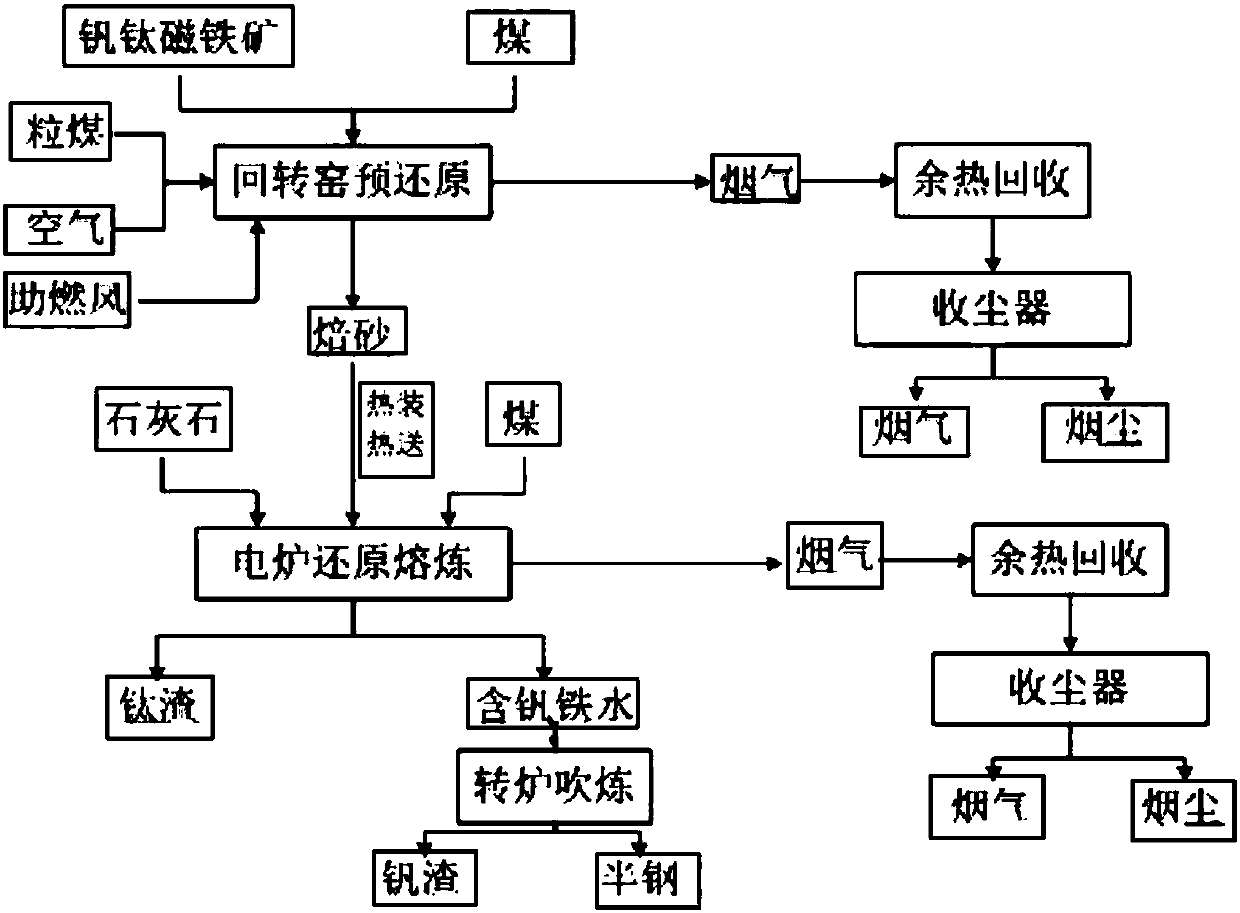

Vanadium-titanium magnetite treatment method

A technology of vanadium-titanium magnetite and processing method, which is applied in the field of metallurgy, can solve the problems of high cost and energy consumption, increase of process flow, low grade of titanium slag and titanium, reduce investment cost and production cost, reduce environmental pollution, The effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

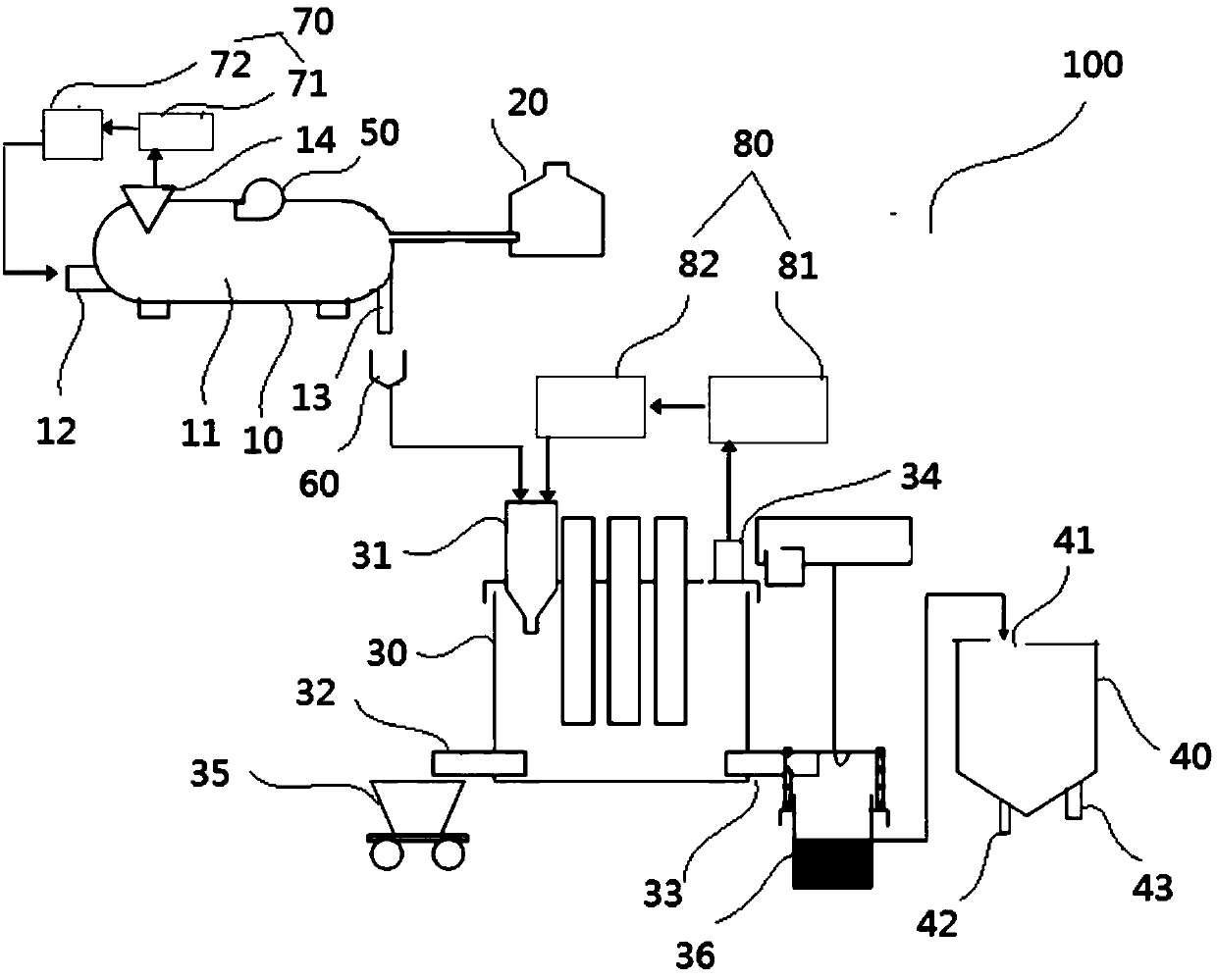

Method used

Image

Examples

Embodiment 1

[0070]Take the vanadium-titanium magnetite rough ore with a medium iron grade of 12%, and obtain the vanadium-titanium magnetite concentrate with an iron grade of 32% after ore separation; mix the vanadium-titanium magnetite concentrate with coal and directly add it to the rotary kiln Carry out pre-reduction, the weight of coal is 30% of the weight of vanadium-titanium magnetite concentrate, the particle size of vanadium-titanium magnetite concentrate is 4.2mm, the particle size of coal is 14.7mm, the temperature of pre-reduction in the rotary kiln is 1100 ℃ , the pre-reduction time is 7.0h. During the pre-reduction process, pelletized coal is injected into the kiln head of the rotary kiln as fuel, and air is injected into the kiln body of the rotary kiln to support combustion. The carbon monoxide and flue gas produced by the pelletized coal combustion The flow direction is opposite to that of the material, and finally, calcine and rotary kiln flue gas with a metallization rate...

Embodiment 2

[0073] Take the vanadium-titanium magnetite rough ore with a medium iron grade of 27%, and obtain the vanadium-titanium magnetite concentrate with an iron grade of 43% after ore separation; mix the vanadium-titanium magnetite concentrate with coal and directly add it to the rotary kiln Carry out pre-reduction, the weight of coal is 40% of the weight of vanadium-titanium magnetite concentrate, the particle size of vanadium-titanium magnetite concentrate is 4.7mm, the particle size of coal is 15.9mm, the temperature of pre-reduction in the rotary kiln is 1200 ℃ , the pre-reduction time is 5.1h. During the pre-reduction process, pelletized coal is injected into the kiln head of the rotary kiln as fuel, and air is injected into the rotary kiln body to support combustion. The flow direction of carbon monoxide and flue gas produced by pelletized coal combustion is consistent with The flow direction of the material is opposite, and finally, the calcine with a metallization rate of 63....

Embodiment 3

[0076] Get the vanadium-titanium magnetite coarse ore that the middle iron grade is 38%, obtain the iron grade after ore dressing and be the vanadium-titanium magnetite concentrate of 59%, the particle size of the vanadium-titanium magnetite concentrate is 3.6mm; The iron ore concentrate is mixed with coal with a particle size of 18.8mm and then directly added to the rotary kiln for pre-reduction. The weight of the coal is 60% of the weight of the vanadium-titanium magnetite concentrate. The pre-reduction temperature in the rotary kiln is 1300 °C. The reduction time is 2.0h. During the pre-reduction process, pelletized coal is injected into the kiln head of the rotary kiln as fuel, and air is injected into the kiln body of the rotary kiln to support combustion. The flow direction of the material is opposite. Finally, the calcine and the flue gas of the rotary kiln are obtained with a metallization rate of 65.4%. Send it to the electric furnace for reduction smelting, and add l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com