Durable volatile antirust nonwoven fabric and preparation method thereof

A gas phase anti-rust, non-woven fabric technology, applied in the direction of textiles and papermaking, coating, paper coating, etc., can solve the problems of durability and poor use, and achieve good durability, low cost and excellent anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

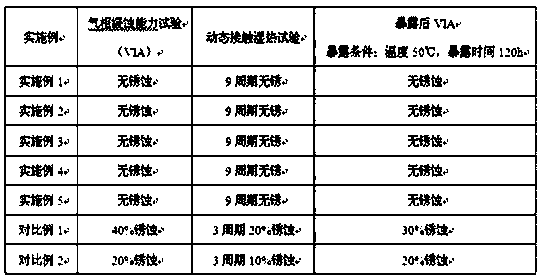

Examples

Embodiment 1

[0030] A kind of preparation method of durable vapor phase antirust nonwoven fabric is characterized in that the specific preparation method is as follows:

[0031] (1) Alkaline solution prepared with benzotriazole, sodium hydroxide, and water at a mass ratio of 100:0.3-0.5:100-200; alkaline solution of vapor phase corrosion inhibitor, sodium silicate, and water at a mass ratio of 100 :200:30 with magnetic stirring, stirring for 30 minutes to form a gel solution;

[0032] (2) Disperse the gel liquid obtained in step (1) with silane coupling agent, starch, and aluminum oxide at a mass ratio of 100:3:1:0.5 in a high mixer at a speed of 450 rpm for 15 minutes, and spray dry to obtain particles Then melamine is pre-dissolved with hot water and further dispersed with the particles, so that melamine is deposited on the surface of the particles with a deposition thickness of 15 μm. The reaction environment is adjusted to a slightly acidic environment with pH=5.5. Excessive formaldeh...

Embodiment 2

[0037] A kind of preparation method of durable vapor phase antirust nonwoven fabric is characterized in that the specific preparation method is as follows:

[0038] (1) Alkaline liquid prepared with benzotriazole derivatives, sodium hydroxide, and water at a mass ratio of 100:0.5:150; alkaline liquid of vapor phase corrosion inhibitor, sodium silicate, and water at a mass ratio of 100:250 :30 with magnetic stirring, stirring for 45min to form a gel solution;

[0039] (2) Disperse the gel solution obtained in step (1) with silane coupling agent, starch, and aluminum oxide in a high mixer at a speed of 200 rpm for 20 minutes at a mass ratio of 100:5:2:1, and spray dry to obtain particles Then melamine is pre-dissolved with hot water and further dispersed with the particles, so that melamine is deposited on the surface of the particles with a deposition thickness of 20 μm. The reaction environment is adjusted to a slightly acidic environment with pH=6.5. Excessive formaldehyde i...

Embodiment 3

[0044] A kind of preparation method of durable vapor phase antirust nonwoven fabric is characterized in that the specific preparation method is as follows:

[0045] (1) The alkaline solution prepared by imidazole, sodium hydroxide and water at a mass ratio of 100:0.4:100; the alkaline solution of gas phase corrosion inhibitor is mixed with sodium silicate and water at a mass ratio of 100:200:40 Magnetic stirring, stirring for 30min to form a gel solution;

[0046] (2) Disperse the gel solution obtained in step (1) with silane coupling agent, starch, and aluminum oxide in a high mixer at a speed of 450 rpm for 45 minutes at a mass ratio of 100:5:2:0.5, and spray dry to obtain particles Then melamine is pre-dissolved with hot water and further dispersed with the particles, so that melamine is deposited on the surface of the particles with a deposition thickness of 20 μm, and the reaction environment is adjusted to a slightly acidic environment with pH=5.55. Excessive formaldehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com