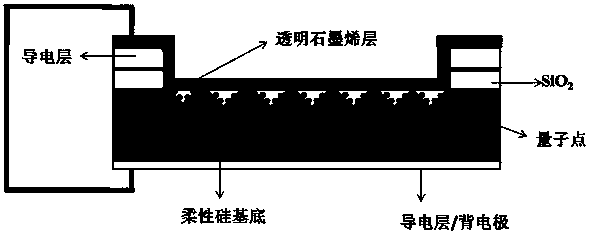

Flexible graphene/silicon solar cell preparation method

A technology of silicon solar cells and flexible graphite, applied in the field of solar cells, to achieve the effect of improving absorption and improving separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the preparation method of flexible graphene silicon solar cell of the present invention, concrete operation is as follows:

[0025] Divide the area into 1.5×1.5cm 2 The monocrystalline silicon wafers were ultrasonically cleaned with ethanol and deionized water for 10 minutes in sequence, and the cleaned silicon wafers were soaked in a KOH solution with a mass fraction of 45% for 4 hours at a temperature of 60°C. After etching, the silicon wafers The thickness of the wafer is about 30 microns; leave the middle part of the upper surface of the thinned flexible silicon wafer as a window, and seal the rest of the upper surface except the window, and then place the processed silicon wafer in a 1% Soak in HF acid solution for 60 minutes to remove the oxide layer on the surface of the window and the back of the silicon wafer;

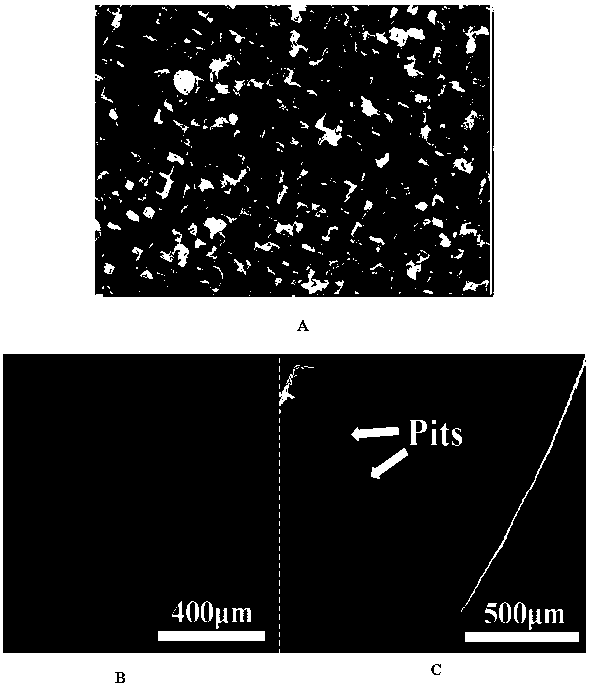

[0026] Place the flexible silicon wafer on HF-Cu(NO 3 ) 2 -H 2 o 2 In the etching solution, the concentration of HF in the etching s...

Embodiment 2

[0031]Embodiment 2: the preparation method of flexible graphene silicon solar cell of the present invention, concrete operation is as follows:

[0032] Divide the area into 1.5×1.5cm 2 The monocrystalline silicon wafers were ultrasonically cleaned with ethanol and deionized water for 15 minutes in turn, and the cleaned silicon wafers were soaked in 20% KOH solution for 3 hours at a temperature of 40°C. After etching, the silicon wafers The thickness is about 80 microns; leave the middle part of the upper surface of the thinned flexible silicon wafer as a window, and seal the rest of the upper surface except the window, and place the treated silicon wafer in 40% HF acid Soak in the solution for 1min to remove the oxide layer on the back of the silicon wafer;

[0033] Place the flexible silicon wafer on HF-Cu(NO 3 ) 2 -H 2 o 2 In the etching solution, the concentration of HF in the etching solution is 0.1mol / L, Cu(NO 3 ) 2 The concentration is 0.01mol / L, H 2 o 2 The con...

Embodiment 3

[0034] Embodiment 3: the preparation method of flexible graphene silicon solar cell of the present invention, concrete operation is as follows:

[0035] Divide the area into 1.5×1.5cm 2 The monocrystalline silicon wafers were ultrasonically cleaned with ethanol and deionized water for 15 minutes in turn, and the cleaned silicon wafers were soaked in 90% NaOH solution for 0.2 hours at a temperature of 60°C. After etching, the silicon wafers The thickness is about 20 microns; leave the middle part of the upper surface of the thinned flexible silicon wafer as a window, and seal the rest of the upper surface except the window, and place the treated silicon wafer in 5% HF acid Soak in the solution for 10 minutes to remove the oxide layer on the window surface and the back of the silicon wafer;

[0036] Place the flexible silicon wafer on HF-Cu(NO 3 ) 2 -H 2 o 2 In the etching solution, the concentration of HF in the etching solution is 4.6mol / L, Cu(NO 3 ) 2 The concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com