Aluminum oxynitride ceramic powder and preparation method thereof

A ceramic powder and aluminum oxynitride technology, which is applied in the field of aluminum oxynitride ceramic powder and its preparation, can solve the problems of high cost and limited application range, and achieve the effect of low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

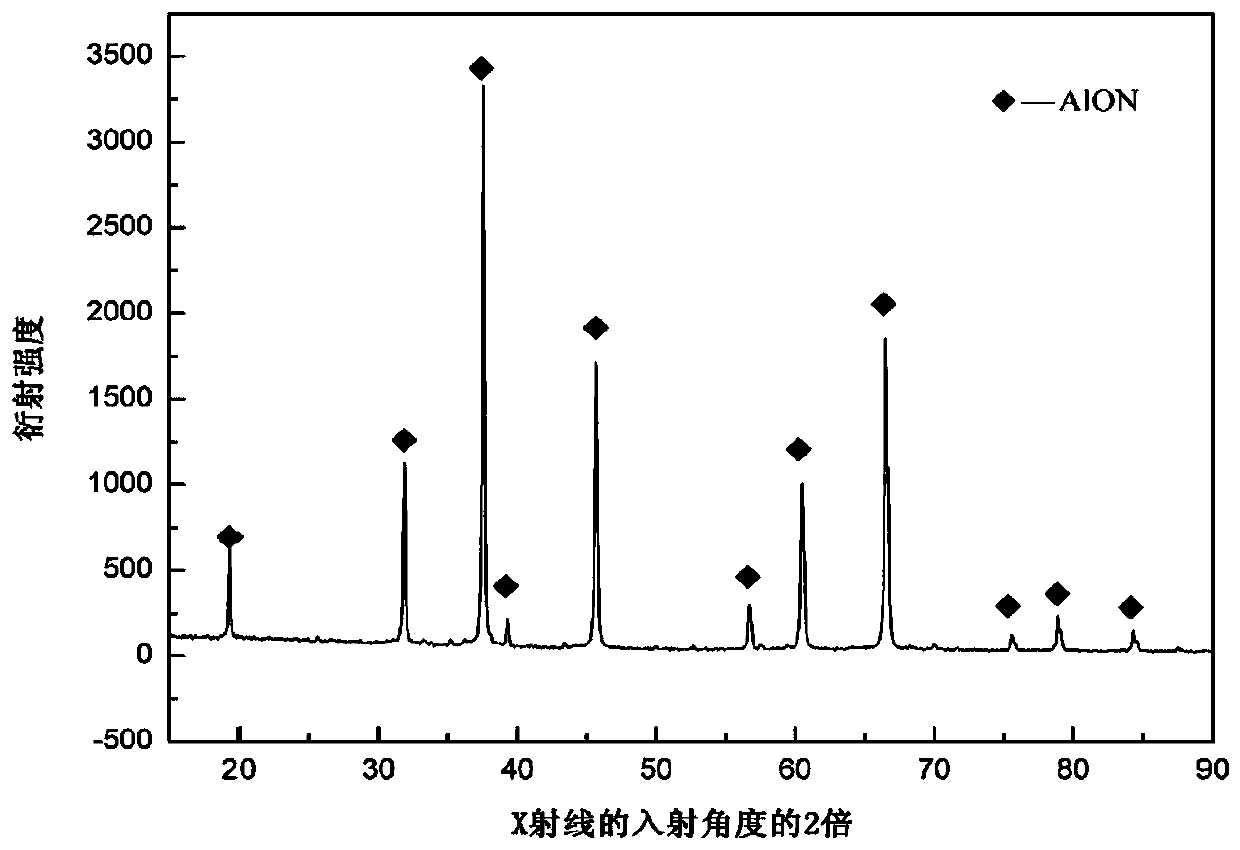

Embodiment 1

[0041] A preparation method of the aluminum oxynitride ceramic powder of the present invention comprises the following steps:

[0042] (1) Preparation of aluminum source and carbon source: Dissolve aluminum sec-butoxide (183mL, 0.72mol) in absolute ethanol, then slowly add 8mL deionized water into the ethanol solution of aluminum sec-butoxide to obtain sec-butanol Aluminum mixed solution, wherein the concentration of aluminum sec-butoxide is 1.4mol / L; and rapidly stir to prepare 580mL transparent and stable aluminum sec-butoxide sol.

[0043] Glucose (14.4 g, 80 mmol) and urea (3.6 g, 60 mmol) were dissolved in 28 mL of deionized water, and 14 mL of ethylene glycol was added to obtain a carbon source mixed solution.

[0044] (2) Preparation of aluminum oxynitride ceramic precursor: Mix the aluminum sec-butoxide sol obtained in step (1) with the carbon source mixed solution, and stir at 60°C to make aluminum sec-butoxide generate under the action of water and ethanol The hydro...

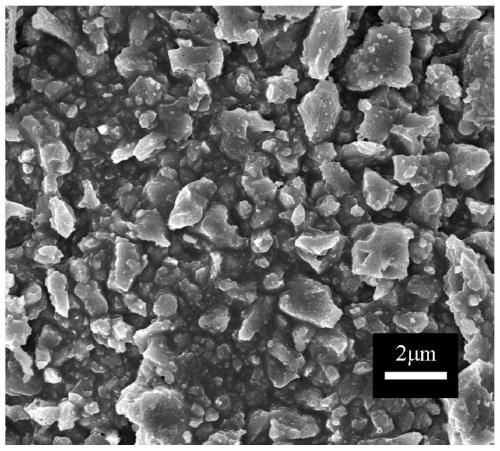

Embodiment 2

[0049] A preparation method of the aluminum oxynitride ceramic powder of the present invention comprises the following steps:

[0050] (1) Preparation of aluminum source and carbon source: Dissolve aluminum sec-butoxide (200mL, 0.8mol) in absolute ethanol, then slowly add 10mL deionized water into the ethanol solution of aluminum sec-butoxide to obtain sec-butanol Aluminum mixed solution, wherein the concentration of aluminum sec-butoxide is 1.2mol / L; and rapidly stirred to prepare 665mL transparent and stable aluminum sec-butoxide sol.

[0051] Glucose (14.4 g, 80 mmol) and urea (3.6 g, 60 mmol) were dissolved in 28 mL of deionized water, and 14 mL of ethylene glycol was added to obtain a carbon source mixed solution.

[0052] (2) Preparation of aluminum oxynitride ceramic precursor: mix the aluminum sec-butoxide sol obtained in step (1) with the carbon source mixed solution, and fully stir at 60°C for 2 hours, so that the aluminum sec-butoxide can react with water and ethano...

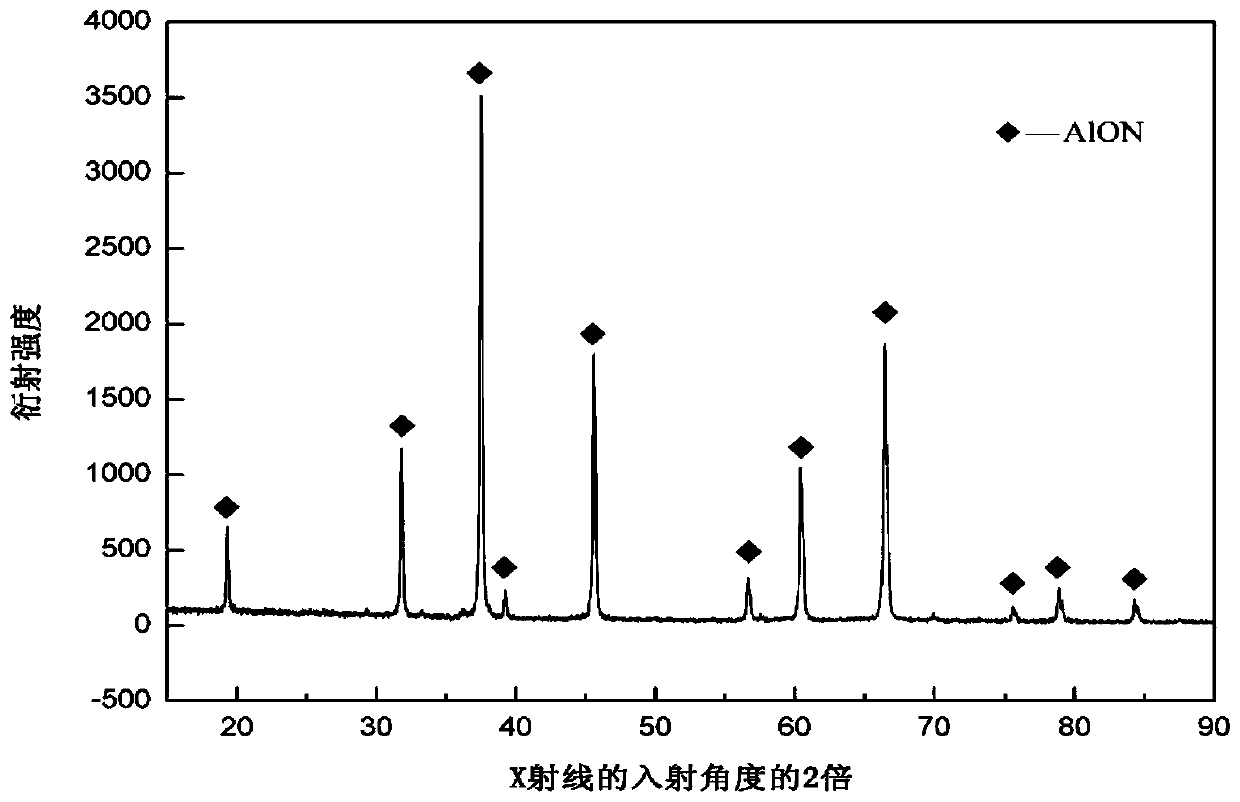

Embodiment 3

[0057] A preparation method of the aluminum oxynitride ceramic powder of the present invention comprises the following steps:

[0058] (1) Preparation of aluminum source and carbon source: Dissolve aluminum sec-butoxide (200mL, 0.8mol) in absolute ethanol, then slowly add 10mL deionized water into the ethanol solution of aluminum sec-butoxide to obtain sec-butanol Aluminum mixed solution, wherein the concentration of aluminum sec-butoxide is 1.3mol / L; and rapidly stirred to prepare 615mL transparent and stable aluminum sec-butoxide sol.

[0059] Glucose (18 g, 0.1 mol) and urea (4.8 g, 80 mmol) were dissolved in 28 mL of deionized water, and 14 mL of ethylene glycol was added to obtain a carbon source mixed solution.

[0060](2) Preparation of aluminum oxynitride ceramic precursor: mix the aluminum sec-butoxide sol obtained in step (1) with the carbon source mixed solution, and fully stir at 60°C for 2 hours, so that the aluminum sec-butoxide can react with water and ethanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com