Process for making dried blueberries

A processing technology, blueberry fruit technology, applied in food drying, food ultrasonic treatment, food ingredients as color, etc., can solve the problems of uneven taste of dried blueberry fruit, ineffective sugar penetration, high labor intensity, etc., to achieve better quality Good quality, good quality of dried fruit and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: manual production of dried blueberry fruit.

[0033] 1. Materials and Reagents

[0034] Fresh blueberries (purchased from Yongjia Jujun Farm), white granulated sugar (purchased from the farmers’ market in southern Zhejiang, in bulk), water, L-ascorbic acid (Qingdao Tianxin Food Additive Co., Ltd., food grade)

[0035] 2. Instruments and equipment

[0036] Balance (Electronic scales) Ohaus Instrument (Shanghai) Co., Ltd. manufacturing (OHAUSCORPORATION), induction cooker (POT01Induction cooker) Pentium Electric (Shanghai) Co., Ltd., electric blast drying oven Suzhou Haoyue Electric Equipment Manufacturing Factory, freeze dryer ( SCTENTZ-100F) Ningbo Xinzhi Biotechnology Co., Ltd., ultrasonic machine (self-developed).

[0037] 3. Specific steps:

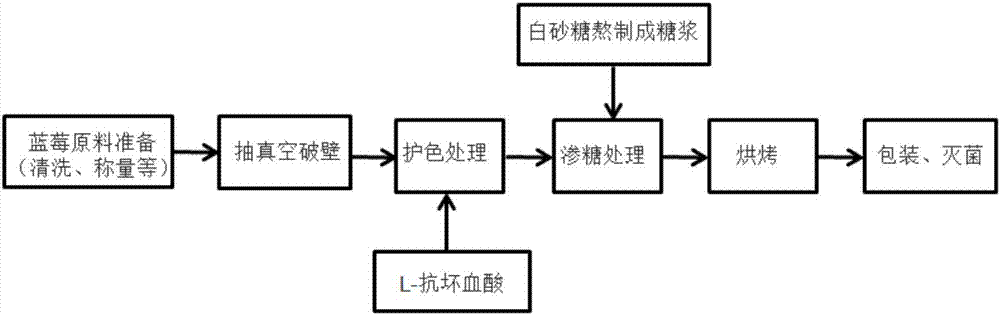

[0038] (1), the processing technology of dried blueberry fruit is as follows: figure 1 Shown:

[0039] ① Raw material fruit selection process: fresh blueberries or thawed blueberry frozen fruits can be selecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com