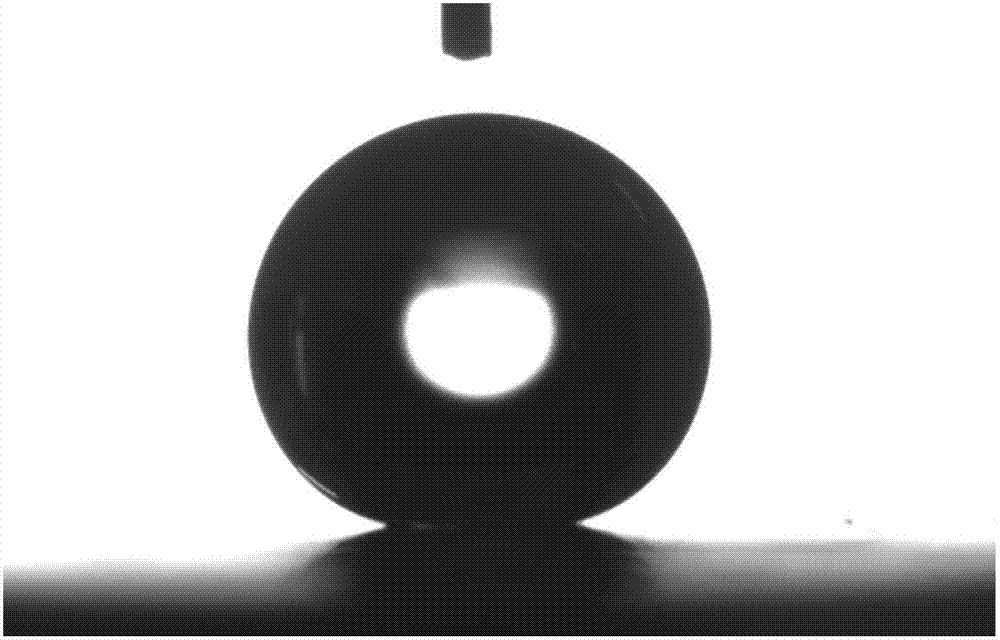

Transparent super-hydrophobic glass with anti-fog and dewdrop self-cleaning functions and preparation method of transparent super-hydrophobic glass

A super-hydrophobic, dew-drop technology, applied in the field of material chemistry, to achieve the effect of low cost, simple processing technology and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

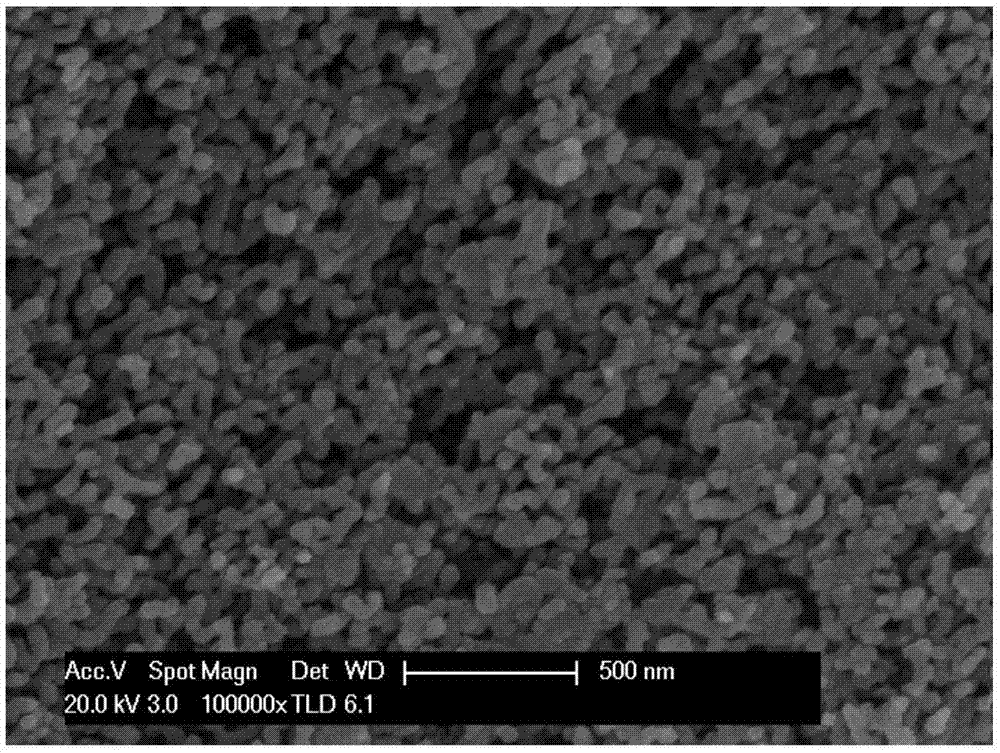

[0032] The transparent superhydrophobic glass with anti-fog and dewdrop self-cleaning functions of the present invention is prepared by the following steps:

[0033] (1) The main component of the sodium borosilicate glass used is SiO 2 68 copies, B 2 o 3 23 parts, Na 2 7 parts of O, 2 parts of other elements such as Mg and Ca; place the glass in acetone, absolute ethanol and deionized water in turn, and use a 400w ultrasonic cleaner to ultrasonically clean them for 10 minutes, and dry them in an oven at 80°C for 10 minutes;

[0034] (2) Put the cleaned glass sheet in a tube furnace, heat-preserve it at 700°C for 1 hour, and heat up at a rate of 5-6°C / min, and then cool it with the furnace; and anhydrous ethanol for 15 min, then rinsed with deionized water and washed with N 2 blow dry.

[0035] (3) In parts by mass, 3 parts of hydrofluoric acid, 6 parts of sulfuric acid, and 0.5 parts of ammonium fluoride are dropped into 100 parts of deionized water, and the glass after...

Embodiment 2

[0039] The transparent superhydrophobic glass with anti-fog and dewdrop self-cleaning functions of the present invention is prepared by the following steps:

[0040] (1) The main component of the sodium borosilicate glass used is SiO 2 68 copies, B 2 o 3 23 parts, Na 2 7 parts of O, 2 parts of other elements such as Mg and Ca; place them in acetone, absolute ethanol, and deionized water in turn, and use a 400w ultrasonic cleaner to ultrasonically clean them for 10 minutes, and dry them in an oven at 80°C for 10 minutes;

[0041] (2) Put the cleaned glass sheet in a tube furnace, heat preservation treatment at 680°C for 1.5h, the heating rate is 5-6°C / min, and then cool with the furnace; then use the phase-separated glass Acetone and absolute ethanol were ultrasonically cleaned for 15 min, then rinsed with deionized water and washed with N 2 blow dry.

[0042] (3) In parts by mass, 5 parts of hydrofluoric acid, 6 parts of sulfuric acid, and 1 part of ammonium fluoride ar...

Embodiment 3

[0047] The transparent superhydrophobic glass with anti-fog and dewdrop self-cleaning functions of the present invention is prepared by the following steps:

[0048] (1) The main component of the sodium borosilicate glass used is SiO 2 62 copies, B 2 o 3 28 parts, Na 2 9 parts of O, 1 part of other elements such as Mg, Ca, etc.; place them in acetone, absolute ethanol and deionized water in order to ultrasonically clean them with a 400w ultrasonic cleaner for 10 minutes, and dry them in an oven at 80°C for 10 minutes;

[0049] (2) Place the cleaned glass piece in a tube furnace, heat-preserve it at 620°C for 12 hours, and heat up at a rate of 5-6°C / min, and then cool with the furnace. Afterwards, the glass after the phase separation treatment was ultrasonically cleaned with acetone and absolute ethanol for 15 min, rinsed with deionized water, and washed with N 2 blow dry.

[0050] (3) In parts by mass, 3 parts of hydrofluoric acid, 6 parts of sulfuric acid, and 0.5 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com