Thermal conductive adhesive and substrate-free high-thermal-conductivity double-faced adhesive tape made of thermal conductive adhesive

An adhesive and solvent technology, used in adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problems of low thermal conductivity, uneven dispersion, and reduced adhesive bonding performance, etc. Achieve the effect of increasing thermal conductivity, increasing specific surface area, and increasing peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

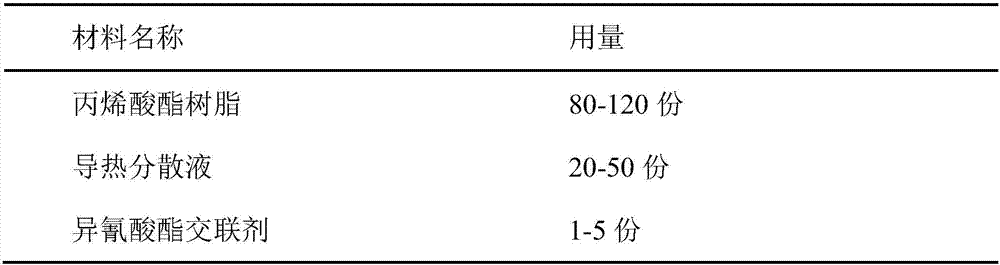

[0029] A thermally conductive adhesive, comprising an acrylate resin, an isocyanate crosslinking agent and a thermally conductive dispersion liquid, is composed of the following parts by weight:

[0030]

[0031] Wherein acrylate resin comprises acrylate monomer, initiator, solvent, rosin pentaerythritol ester and rosin sorbitol ester, and described acrylate monomer comprises butyl acrylate, diethylhexyl acrylate, propylene

[0032]

[0033] The preparation process of the acrylate resin is: synthesize the acrylate monomer, solvent and initiator at a temperature of 60-100°C and a stirring speed of 200-400r / min for 5-30 hours, and then add rosin pentaerythritol ester and rosin sorbitol ester, and stir well.

[0034] The thermally conductive dispersion includes thermally conductive fillers, solvents, coupling agents and surfactants, wherein the thermally conductive fillers are nano-high thermal conductivity graphite and nano-ceramic powder, the coupling agents are KH560, KH...

Embodiment 2

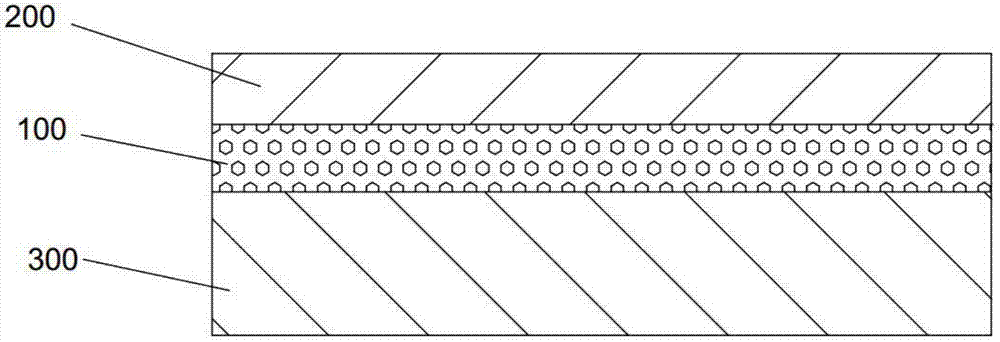

[0039] like figure 1 As shown, a double-sided adhesive with no substrate and high thermal conductivity includes the aforementioned thermally conductive adhesive layer 100, and a first release film 200 and a second release film 300 respectively arranged on both sides of the thermally conductive adhesive layer 100. The first release film The release film 200 is a light release film, the second release film 300 is a heavy release film, the thickness of the first release film 200 is 25-50um, and the release force is 1-20g / 25mm; the second release film The thickness of the film 300 is 50-75um, and the release force is 20-50g / 25mm; the thickness of the thermally conductive adhesive layer 100 is 10-50um, and the peeling strength is 1000-2500g / 25mm.

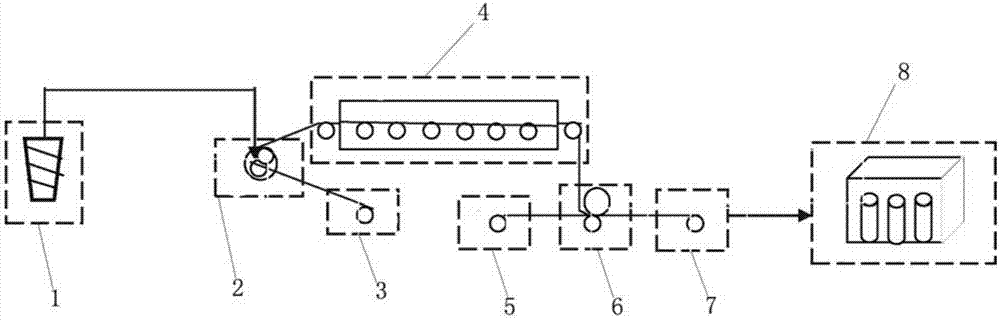

[0040] In one of the specific embodiments, such as figure 2 As shown, a method for preparing double-sided adhesive with no base material and high thermal conductivity. The double-sided adhesive with no base material and high thermal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com