Array-type cell dynamic culturing and regionalization processing micro-fluidic chip, and preparation method and application of same

A microfluidic chip, dynamic culture technology, applied in biochemical equipment and methods, tissue cell/virus culture devices, support/immobilization methods for microorganisms, etc. Shear force dynamic loading and other issues to achieve good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

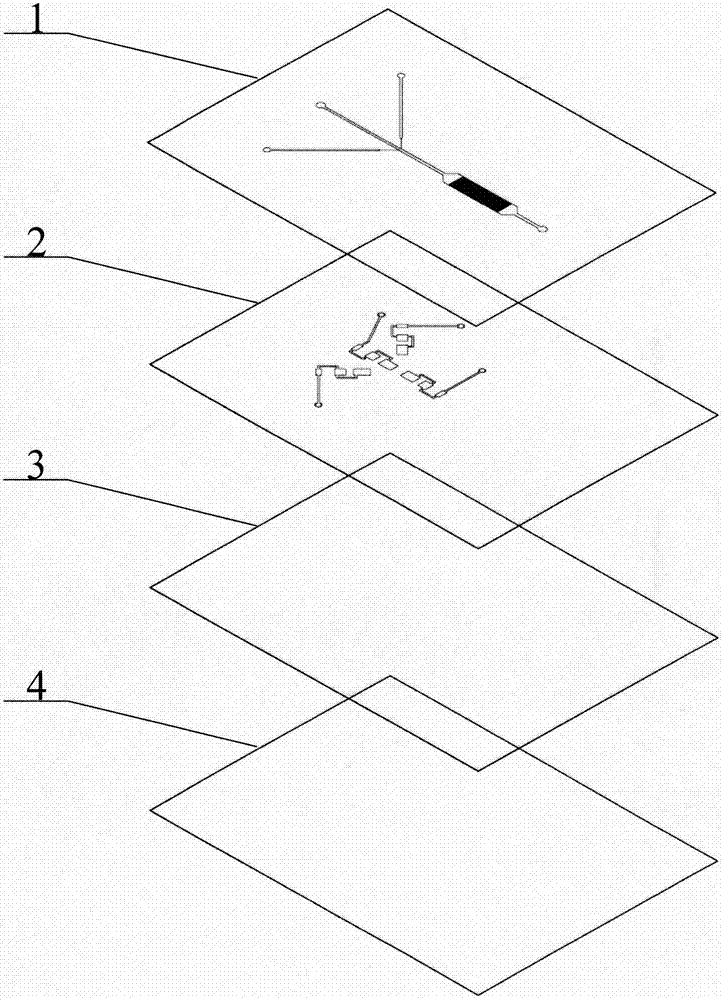

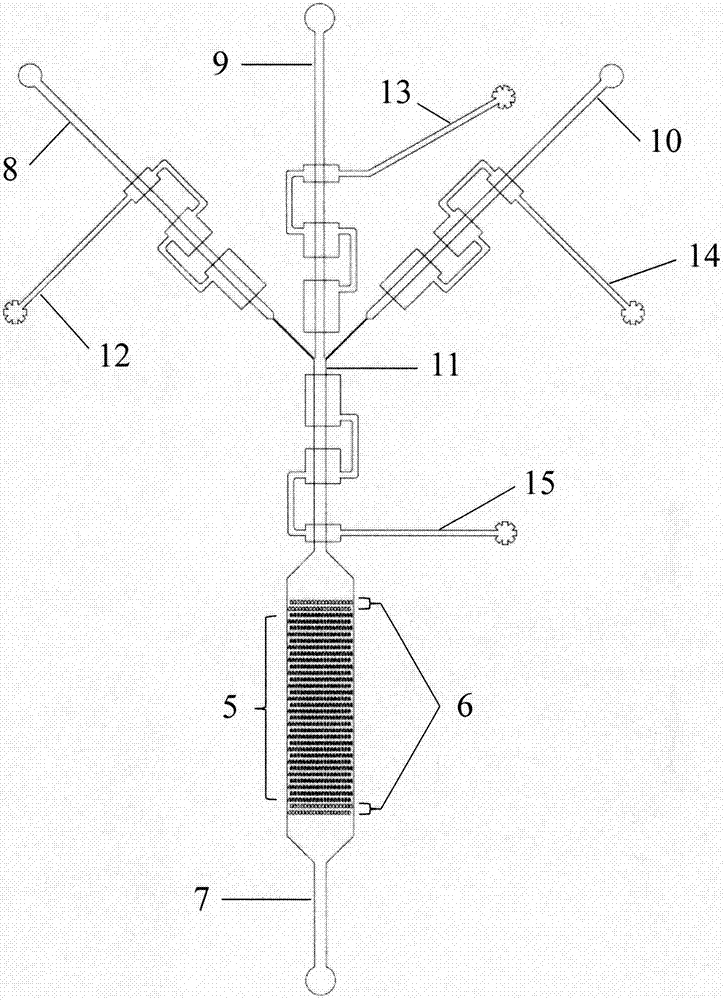

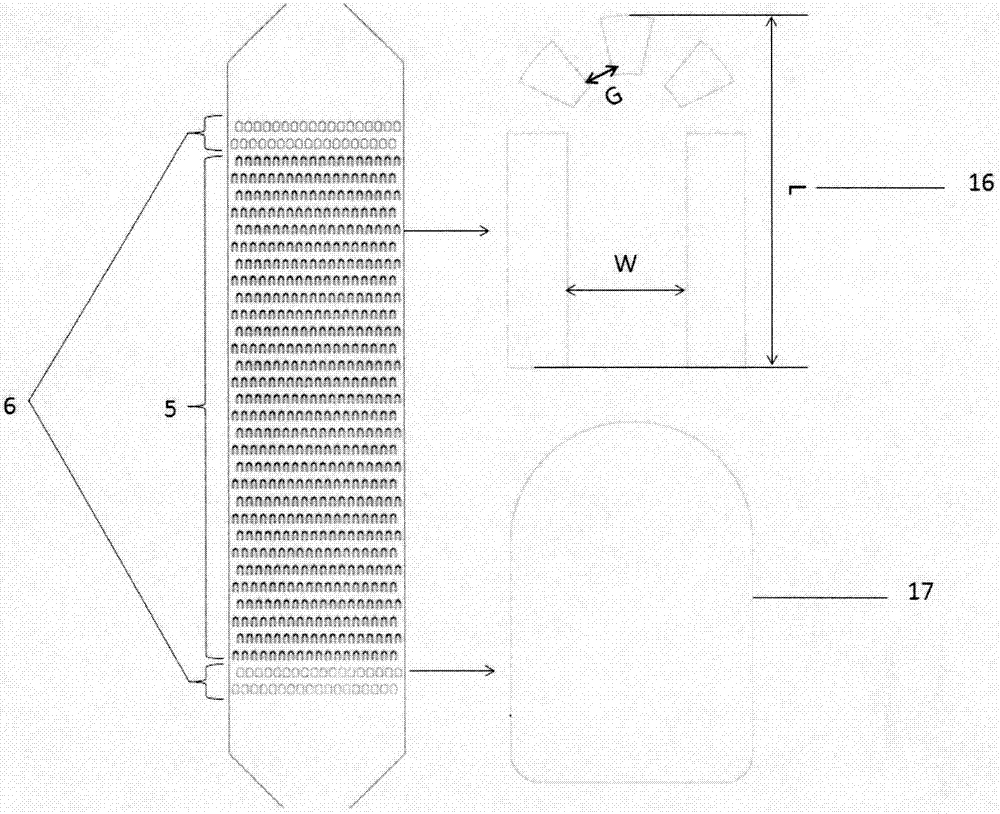

[0038] An array type cell dynamic culture and regionalized processing microfluidic chip, the chip includes a flow layer 1, a control layer 2, a film layer 3 and a glass layer 4 sealed sequentially from top to bottom; the flow layer 1 consists of an array Cell culture area 5, buffer structure area 6, cell inoculation micropipe 7, left liquid inlet micropipe 8, central liquid inlet micropipe 9 and right liquid inlet micropipe 10, the cell inoculation micropipe 7 is used to flow Layer input cells, the central liquid inlet microchannel 9, the left liquid inlet microchannel 8 and the right liquid inlet microchannel 10 are respectively used as the medium inlet microchannel in the center and the biochemical factor / medicine inlet microchannel on both sides. It is used to provide culture medium for cells cultured in an array to realize fluid shear stress loading and regionalized treatment of biochemical factors / drugs; the arrayed cell culture area 5 is provided with several arrayed arra...

Embodiment 2

[0045] The control layer microvalve 13 drives the liquid in the medium inlet micropipe 9 as follows: Figure 5 , Figure 6 shown. When the micropump 13 was in a quiescent state, the liquid in the medium inlet micropipe 9 was also in a quiescent state, as Figure 5 As shown; when the micropump 13 is driven with a pressure of 2 psi and a frequency of 1 Hz, the three microcavities 18, 19, and 20 of the micropump 13 are sequentially deformed to drive the liquid flow in the medium inlet micropipe 9, as Figure 6 As shown, so as to achieve real-time update of the medium.

Embodiment 3

[0047] This embodiment takes the array culture of osteoblast-like cells IDG-SW3 in a microfluidic chip as an example.

[0048] Step 1. Pretreating the microfluidic chip. First, the prepared microfluidic chip in Example 1 was sterilized by ultraviolet irradiation, and then the fluid layer microchannel and cell culture area were protein-coated with type I collagen, 0.15mg / mL, 37°C, 2h, Then use serum-free α-MEM medium to rinse the fluidized layer microchannel and cell culture area.

[0049] Step 2. Prepare osteoblast-like cell IDG-SW3 suspension. Culture IDG-SW3 cells by conventional cell culture method, digest with trypsin to obtain cells in the logarithmic growth phase, centrifuge the cell suspension at 800 rpm for 5 minutes to remove trypsin, resuspend the cells in α-MEM medium containing 10% fetal bovine serum, The cell density was adjusted to 0.5×10 6 cells / mL.

[0050] Step 3, inoculating cells. Drive the micropump 15 just below the main pipeline 11 with 2psi gas pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com