Measuring method for high-zinc slag of wet-process zinc smelting system and organic substances in solution

A technology for hydrometallurgical zinc smelting and determination method, which is applied in the direction of measuring device, improvement of process efficiency, preparation of test samples, etc., to achieve the effects of energy saving, good reproducibility and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for the determination of high zinc slag and organic matter in the solution of the zinc hydrometallurgy system, which uses an organic solvent to dissolve the high zinc slag of the wet zinc smelting system and the organic matter in the solution, and then uses an extractant to dissolve the high zinc slag of the wet zinc smelting system. and extracting the solution to the organic phase, and then using a complexing agent to wash the metal ions in the organic phase, and then concentrating the washed loaded organic phase at low temperature and weighing, so as to obtain the total content of the organic matter.

[0042] Further, the use of organic solvents to dissolve the high zinc slag and organic matter in the solution of the wet zinc smelting system is to weigh the samples of wet calcination, wet leaching slag, wet flotation concentrate and flotation tailings, and take the samples Put it into the test bottle, then add an organic solvent to dissolve the organic matter ...

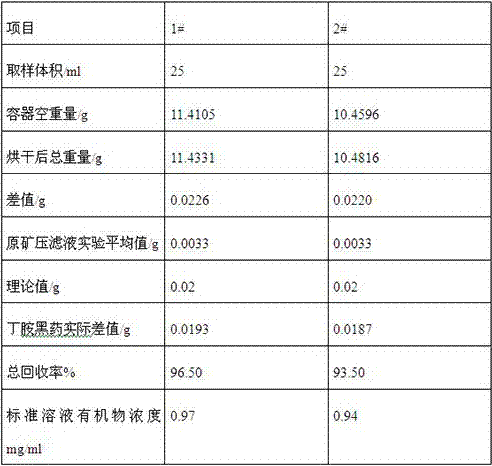

Embodiment 2

[0058] The principle of embodiment 2 is basically the same as that of embodiment 1. It is a method for measuring high zinc slag and organic matter in solution in a zinc hydrometallurgy system. The solution will be returned to the zinc smelting system) 50ml two parts were put into the separatory funnel, and then extracted with cyclohexane, then washed with 1% EDTA-disodium salt and water to load the organic matter, and the washed organic phase was concentrated at low temperature, After dehydration and weighing, the weights of the organic matter were 0.0028g and 0.0030g, respectively. According to the following formula (1), the organic matter content of the flotation tail liquid was calculated as 0.056g / L and 0.0058g / L respectively.

[0059] Liquid sample organic matter content (g / L) = ×1000 (1)

[0060] W1 - empty weight of the weighing bottle;

[0061] W2 - total weight of weighing bottle and organic matter;

[0062] V - sampling volume.

Embodiment 3

[0064] The principle of embodiment three is basically the same as that of embodiment one. It is a method for measuring the high zinc slag and organic matter in the solution of a wet zinc smelting system. In this embodiment, 10.0 g of the zinc leaching residue filter cake of a certain wet zinc smelting plant is weighed. Put it into a 250ml conical flask, then add 10-15ml of acetone reagent to dissolve, cover tightly with a rubber stopper, shake for 5 minutes, then use rapid quantitative filter paper for liquid-solid separation, wash the conical flask and funnel with acetone, and then use cyclohexane After extraction, the loaded organic matter was washed with 1% EDTA-disodium salt, water, etc., and the washed organic phase was concentrated at low temperature, dehydrated, and weighed, and the weight of the organic matter was 0.0048g. According to the following formula (2), the content of organic matter in the leached slag is calculated to be 0.48kg / t.

[0065] Solid sample organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com