Method for realizing Ni-MOF-74 in-situ growth on foam nickel

A technology of in-situ growth and foamed nickel, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of complex process, high cost, unsuitable for industrial production, etc., to simplify the preparation process, increase the ratio, The preparation method is simple and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

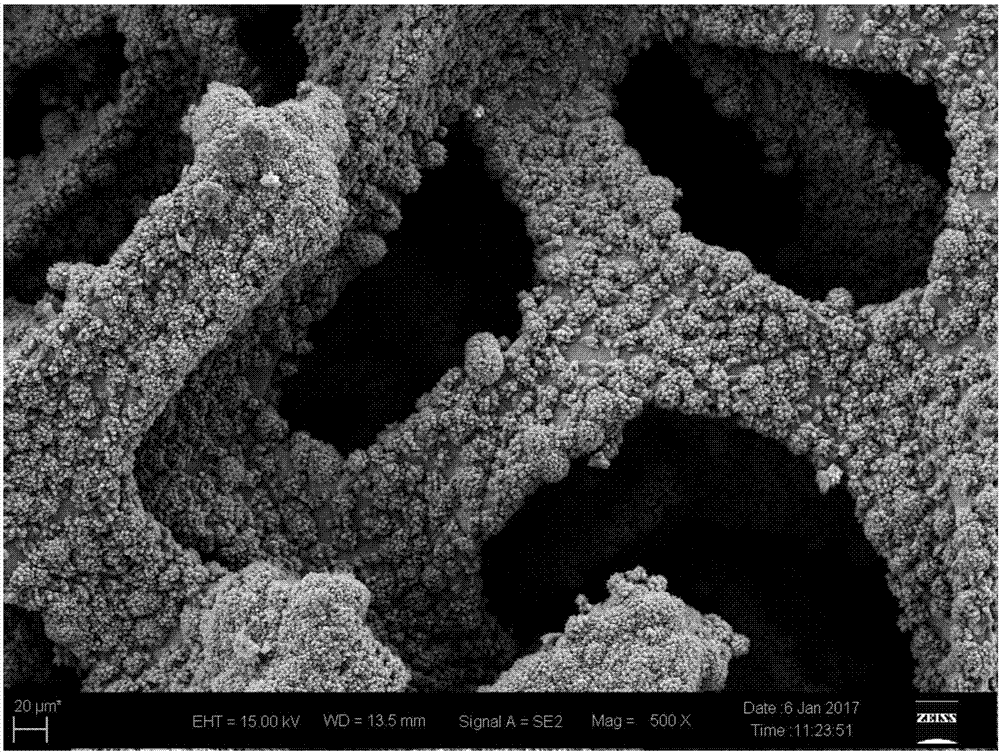

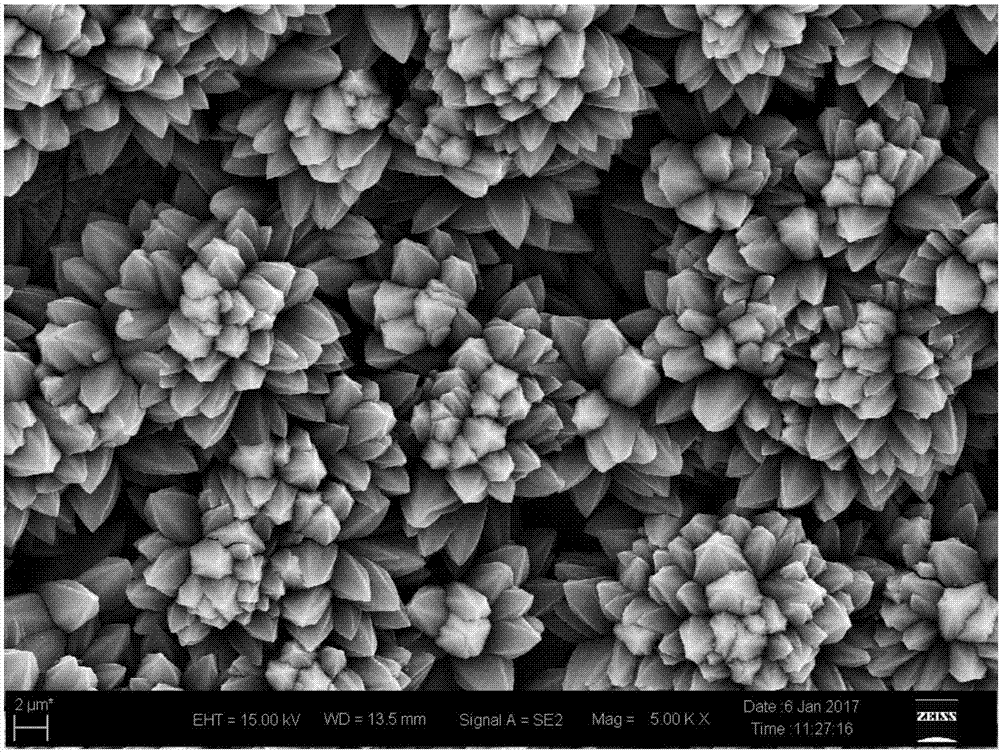

[0019] Embodiment 1: This embodiment is a method for in-situ growth of Ni-MOF-74 on nickel foam, which is specifically carried out according to the following steps:

[0020] 1. Preparation of foamed nickel current collector: Cut the foamed nickel into a cuboid of 1cm×4cm×0.5mm, soak it in a hydrochloric acid aqueous solution with a mass concentration of 1% to 10% for 5min to 10min, and then wash it with ethanol and deionized water in turn. Dry for 12 hours at a temperature of 50°C to 100°C to obtain a foamed nickel current collector;

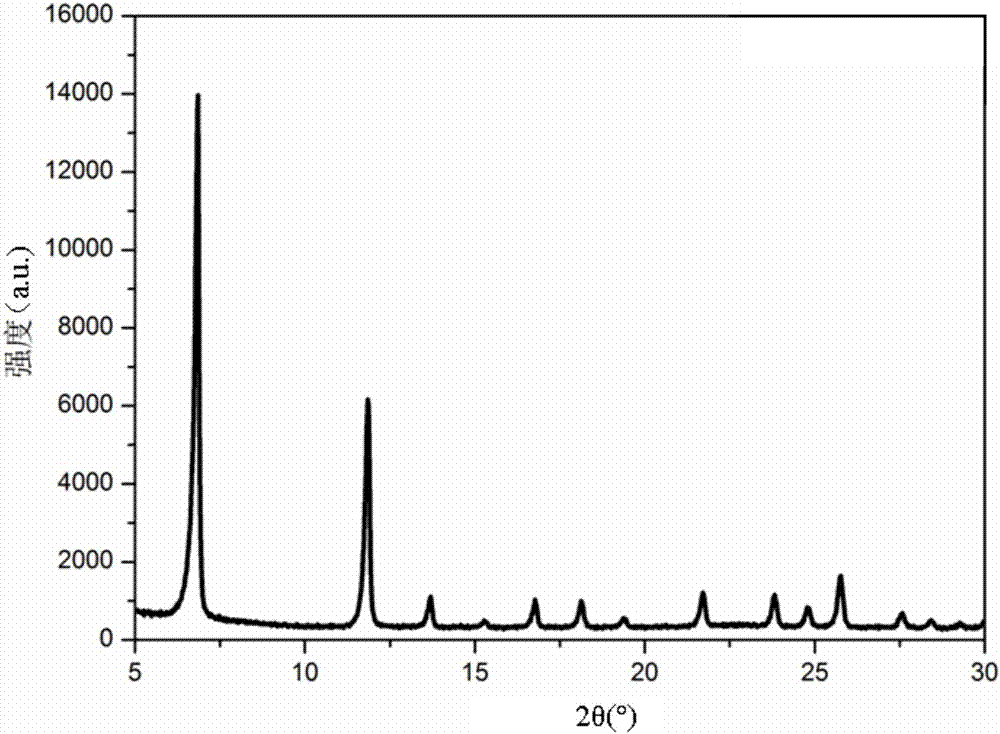

[0021] 2. Preparation of Ni-MOF-74 by hydrothermal method: put 5mL~20mL of 2,5-dihydroxyterephthalic acid solution into the reaction kettle, put the foamed nickel current collector of step 1 vertically into the reactor with 2,5-dihydroxyterephthalic acid solution In the reaction kettle of 5-dihydroxyterephthalic acid solution, add the mixture of absolute ethanol / deionized water, react for 12h-72h under the condition of temperature of 80℃~150℃, c...

specific Embodiment approach 2

[0022] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the nickel foam is cut into a cuboid of 1cm×4cm×0.5mm, soaked in a hydrochloric acid aqueous solution with a mass concentration of 5% for 10 minutes, and then used in turn Washed with absolute ethanol and deionized water, and dried for 12 h at a temperature of 80 °C to obtain a foamed nickel current collector. Others are the same as the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the concentration of the 2,5-dihydroxyterephthalic acid solution described in Step 2 is 0.135 mol / L. Others are the same as the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com