Manufacturing method of composite sweetening agent

A technology for compounding sweeteners and production methods, which can be applied in the functions of food ingredients, food science, and applications, and can solve problems such as increasing costs and restricting the application of trehalose and arabinose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

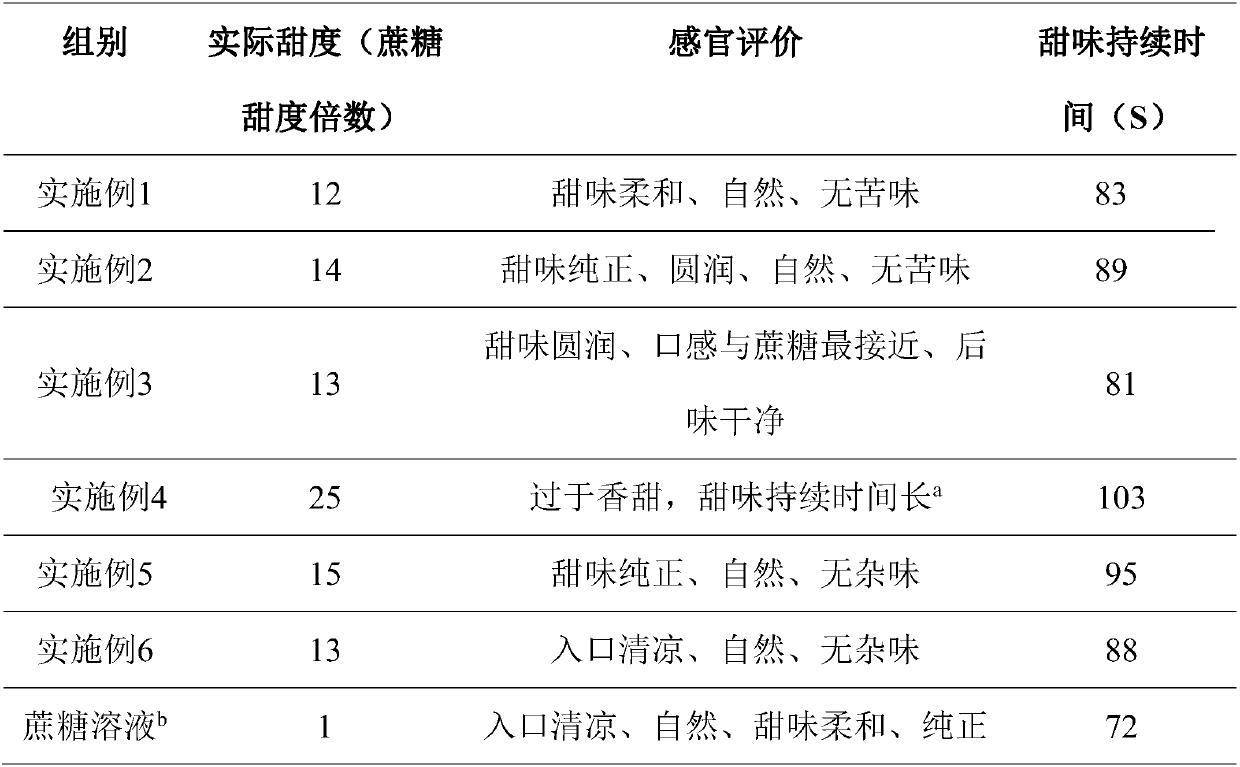

Examples

specific example 1

[0023] Specific example 1: Component A: 300 parts of trehalose, 15 parts of L-arabinose; Component B: 20 parts of dihydrochalcone glycosides, 15 parts of L-glycine; Component C: 10 parts of fructose, 5 parts of sucrose, maltose 5 parts, 10 parts of xylitol, 15 parts of β-cyclodextrin and 1 part of silicon dioxide. The above ingredients are spray-dried or freeze-dried to obtain a compound sweetener powder.

specific example 2

[0024] Specific example 2: Component A: 400 parts of trehalose, 50 parts of L-arabinose; Component B: 30 parts of dihydrochalcone glycosides, 18 parts of L-glycine; Component C: 12 parts of fructose, 15 parts of sucrose, maltose 10 parts, 10 parts of xylitol, 20 parts of β-cyclodextrin and 1 part of silicon dioxide. The above ingredients are spray-dried or freeze-dried to obtain a compound sweetener powder.

specific example 3

[0025] Specific example 3: Component A: 500 parts of trehalose, 100 parts of L-arabinose; Component B: 50 parts of dihydrochalcone glycosides, 20 parts of L-glycine; Component C: 25 parts of fructose, 50 parts of sucrose, maltose 10 parts, 10 parts xylitol, 10 parts β-cyclodextrin, and 1 part silicon dioxide. The above ingredients are spray-dried or freeze-dried to obtain a compound sweetener powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com