Super-hydrophobic nano particles as well as preparation method and application of nano particles

A nanoparticle and superhydrophobic technology, applied in the fields of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as hidden health risks and difficult bonding of film-forming resins, and achieve stable reproduction, easy access to materials, and easy preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

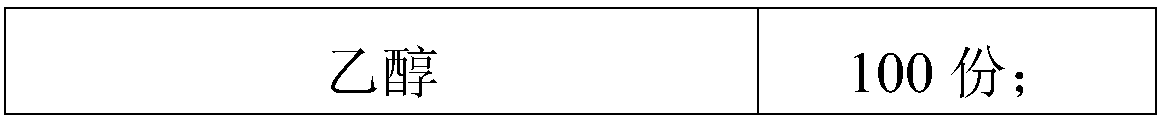

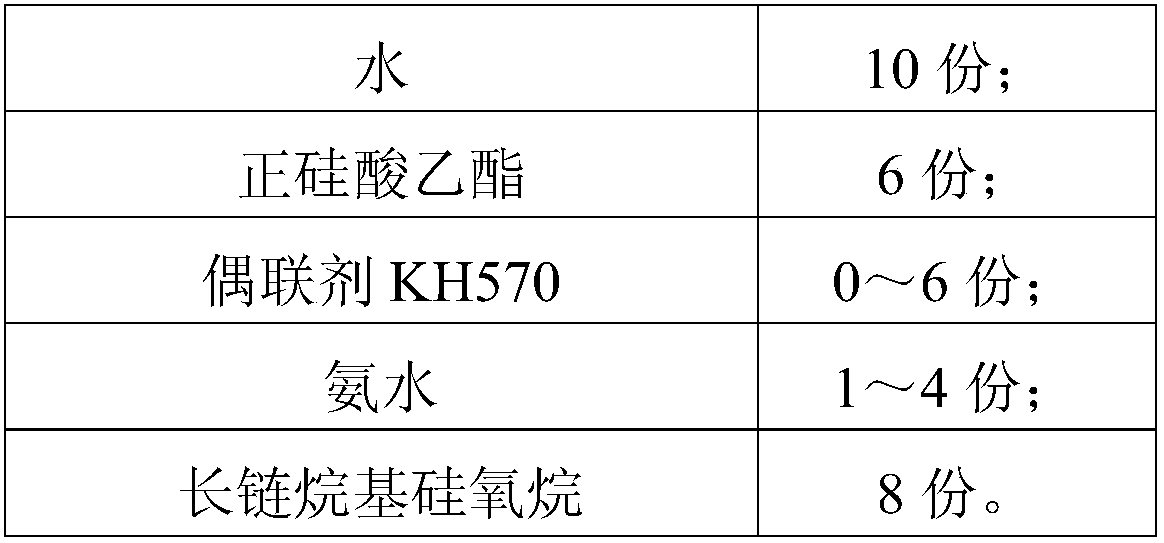

[0037] (1) Under the condition of keeping stirring throughout the whole process, 100 parts of ethanol, 10 parts of water, 5 parts of ethyl orthosilicate and 0 parts of coupling agent KH570 are added to the reactor in order to stir and mix in parts by mass. At the same time, start to heat up to the set reaction temperature of 60° C., then evenly add 4 parts of ammonia water (25% mass concentration, AR) dropwise, keep the constant temperature reflux reaction for 75 minutes after the dropwise addition, and the obtained solution is dispersion A;

[0038] (2), continue to add 8 parts of long-chain alkoxysilane dropwise to the dispersion A, keep the constant temperature reaction temperature set in step (1), the constant temperature reaction is over for 120 minutes, cool to room temperature, and the obtained is superhydrophobic nanoparticle dispersion.

[0039] The above-prepared coating solution (dispersion solution) is spread by conventional spraying or scraping method. After the l...

Embodiment 2~9

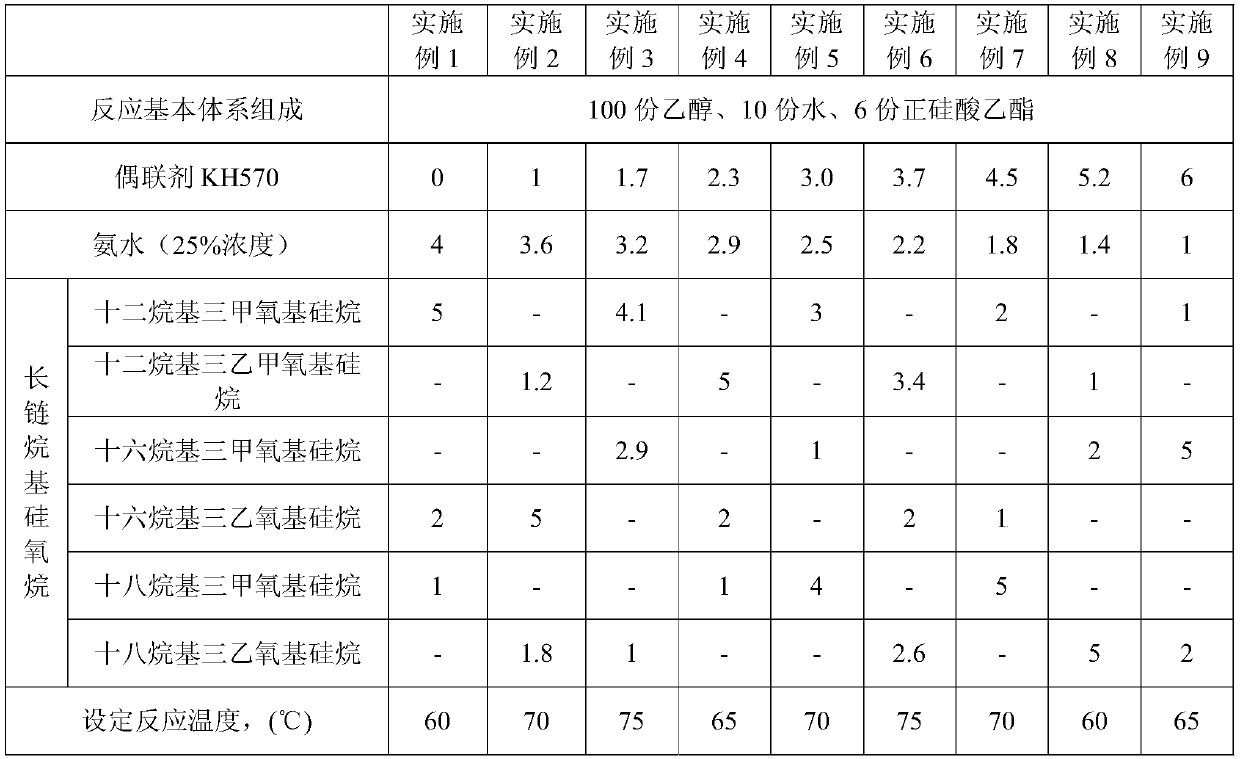

[0044] In Examples 2-9, the operating methods and steps adopted are consistent with those in Example 1, and the specific material ratios, process control parameters and results corresponding to the respective examples are shown in Table 1 and Table 3 for details.

[0045] Table 3 Physicochemical properties of nanoparticle dispersion

[0046]

[0047]

[0048] As can be seen from Table 2 and Table 3, the preparation method and application of a kind of super-hydrophobic nanoparticles of the present invention, by modifying and constructing the microstructure of silicon-containing nanoparticles, prepared a nanostructure that can be used to construct surface micro-nanostructures. nanoparticle dispersion. The dispersion particles have good resin compatibility, and can be well combined with adhesive film-forming resin components (such as water-based epoxy resin, water-based polyester resin, water-based alkyd resin, etc.), forming a functional The super-hydrophobic coating on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com