Odorless sludge advanced treatment method and system thereof

An advanced treatment and odorless technology, applied in sludge treatment, biological sludge treatment, electrochemical sludge treatment, etc., can solve the difficulty of meeting the requirements of post-composting treatment, immature sludge treatment technology, and increased transportation costs and difficulty and other issues, to achieve the effect of simple structure, low cost and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

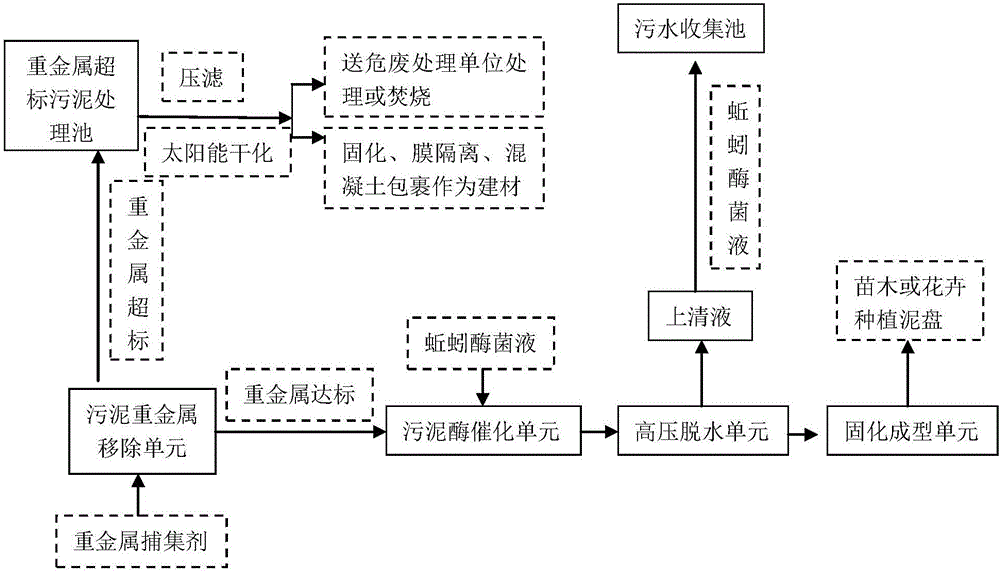

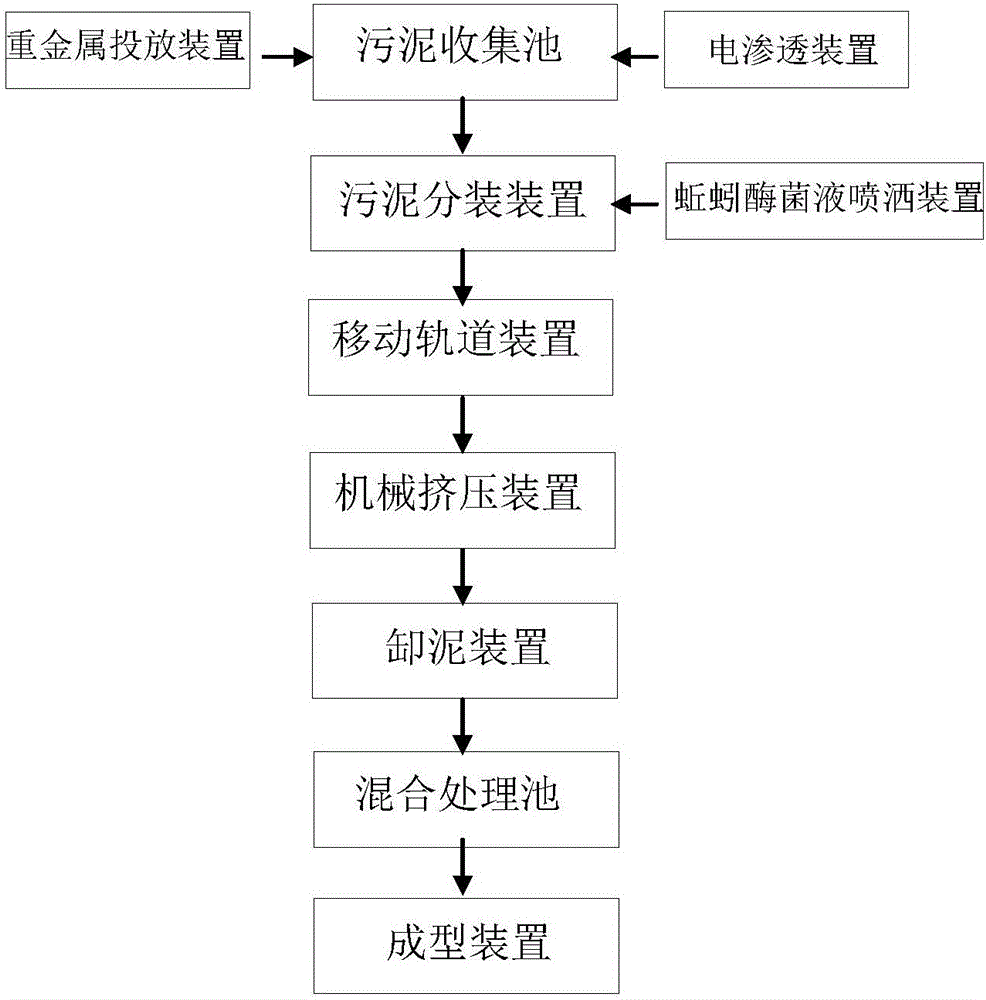

[0029] like figure 1 Shown, be a kind of odorless sludge advanced treatment method of the present invention, comprise the following steps:

[0030] a) Add a heavy metal trapping agent to the sludge collection tank of the sewage treatment plant and perform electroosmosis to remove heavy metals in the sludge;

[0031] b) using a sludge loading hopper to sub-pack the sludge obtained in step a) and put it on the filter cloth, spray the earthworm enzyme liquid to the sludge, wrap the sludge to obtain a sludge bag;

[0032] c) performing mechanical extrusion dehydration on the sludge bag, and reducing the moisture content of the sludge to 30-50% through multi-stage continuous extrusion;

[0033] d) Add pulverized agricultural waste to the sludge obtained in step c), mix evenly, and add a building curing agent to press it into a mud tray f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com