Preparation method of zinc selenide nanowire with controllable composition

A zinc selenide and nanowire technology, applied in chemical instruments and methods, selenium/tellurium compounds, sustainable manufacturing/processing, etc., can solve problems such as zinc selenide nanowire process routes that need to be developed urgently, and achieve product phase composition. control, uniform size distribution, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation operation steps of a composition-controllable zinc selenide nanowire are as follows:

[0031] (1) Dissolve 0.02 mol of selenium powder in 20 mL of tri-n-octylphosphine, and dissolve 0.04 mol of silver nitrate in 30 mL of N,N-dimethylformamide;

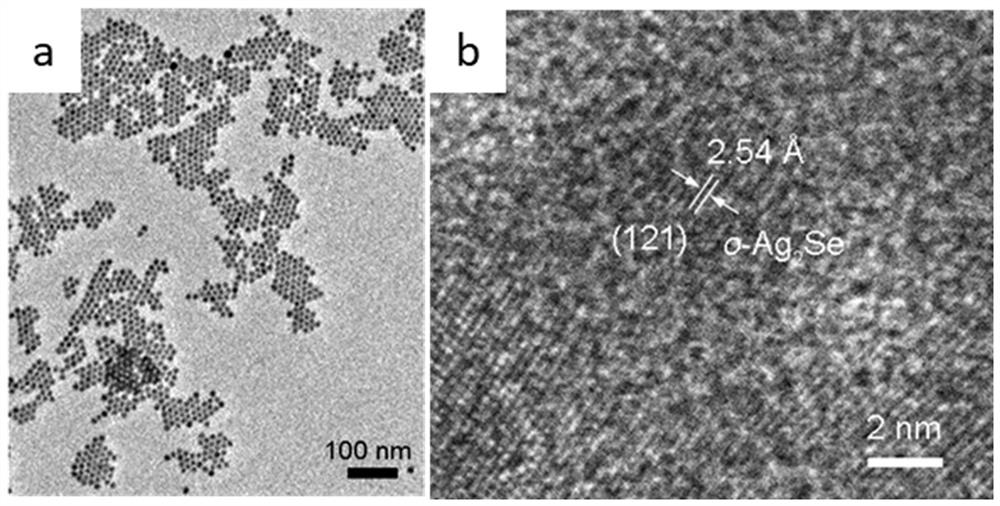

[0032] In a flask with a vacuum stopper, add 500 mL of oleylamine, 20 mL of tri-n-octylphosphine with 0.02 mol of selenium powder, 30 mL of N,N-dimethylformamide with 0.04 mol of silver nitrate and purge with argon After stirring for 30 min, the flask was heated to 120 °C for 20 min, and then the flask was reacted at 200 °C for 15 min. Finally, centrifuge and wash with methanol and ethanol for several times to collect the final precipitated product; the precipitate is dispersed in a mixed solution of 500 mL of cyclohexane and 50 mL of oleylamine to obtain solution A.

[0033] The solution A is a nanoparticle catalyst, and the main component is silver selenide;

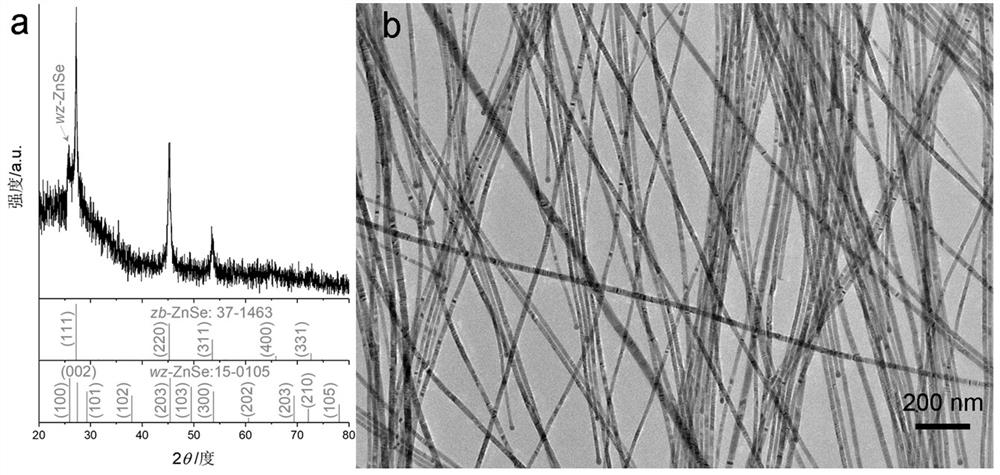

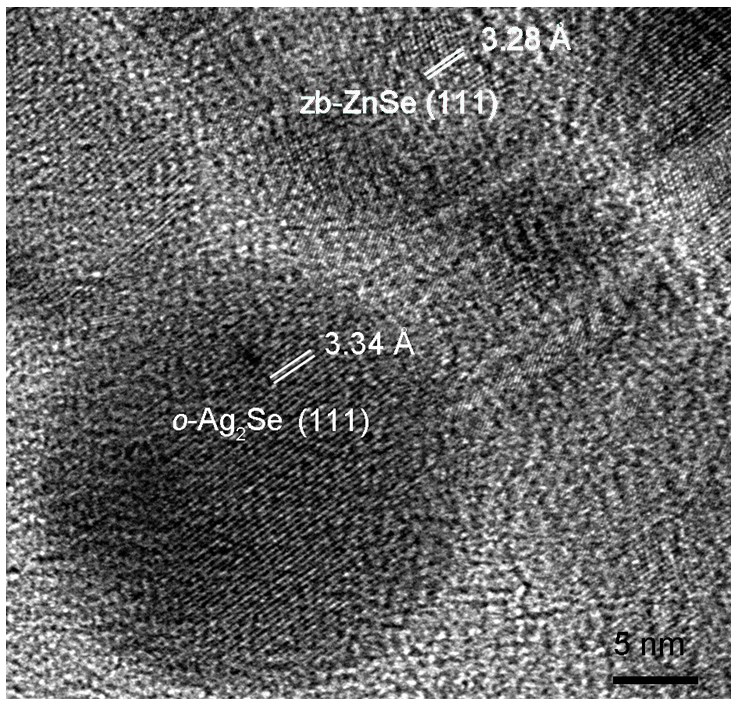

[0034] (2) 1 mL of solution A, 0.4 mmol of seleni...

Embodiment 2

[0038] The preparation operation steps of a composition-controllable zinc selenide nanowire are as follows:

[0039] (1) Dissolve 0.02 mol of selenium powder in 20 mL of tri-n-octylphosphine, and dissolve 0.04 mol of silver nitrate in 30 mL of N,N-dimethylformamide;

[0040] In a flask with a vacuum stopper, add 500 mL of oleylamine, 20 mL of tri-n-octylphosphine with 0.02 mol of selenium powder, 30 mL of N,N-dimethylformamide with 0.04 mol of silver nitrate and purge with argon After stirring for 30 min, the flask was heated to 120 °C for 40 min, and then the flask was reacted at 200 °C for 15 min. Finally, centrifugation and washing with methanol and ethanol were repeated several times, and the precipitate was dispersed in a mixed solution of cyclohexane and oleylamine to obtain solution A.

[0041] The solution A is a nanoparticle catalyst, and the main component is silver selenide.

[0042] (2) Add 1 mL of solution A, 0.4 mmol of selenium powder, 0.4 mmol of zinc oleate,...

Embodiment 3

[0045] The preparation operation steps of a composition-controllable zinc selenide nanowire are as follows:

[0046] (1) Dissolve 0.02 mol of selenium powder in 20 mL of tri-n-octylphosphine, and dissolve 0.04 mol of silver nitrate in 30 mL of N,N-dimethylformamide;

[0047] In a flask with a vacuum stopper, add 500 mL of oleylamine, 20 mL of tri-n-octylphosphine with 0.02 mol of selenium powder, 30 mL of N,N-dimethylformamide with 0.04 mol of silver nitrate and purge with argon Stir for 30 min; then the flask was heated to 120 °C for 20 min, and then the flask was reacted at 200 °C for 15 min. Finally, centrifuge and wash with methanol and ethanol for several times, and disperse the precipitate in a mixed solution of 500 mL of cyclohexane and 50 mL of oleylamine to obtain solution A.

[0048] Solution A is a nanoparticle catalyst, and the main component is silver selenide.

[0049] (2) 1 mL of solution A, 0.5 mmol of zinc oleate, 30 mL of octadecene and 10 mL of oleylamine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Optical bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com