A method for preparing ta2 pure titanium by smelting and recovering ta1 shavings pure titanium residue

A technology of titanium residue and pure titanium, which is applied in the field of titanium material processing, can solve the problems of shortening the smelting and recycling process of TA1 scrap pure titanium residue, long smelting and recycling process, and difficult quality control, so as to reduce the risk of uneven segregation , Milling processing parameters to avoid and reduce the effect of TiO2 addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing TA2 pure titanium by smelting and recovering TA1 shavings of pure titanium residue, comprising the steps of:

[0040] (1) Titanium shavings preparation: the TA1 pure titanium rough slab with a dry, clean surface, no oil stains, water stains, sundries and other foreign matter attached to it is dry-milled with a milling machine, and the surface is machined to obtain a TA1 pure titanium finished slab and Chip-shaped titanium residues, in which the milling cutter head is cooled by blowing compressed air, the cutting amount of the milling cutter head at one time is ≤4mm, and the feeding speed of the milling machine table is ≤120mm / min; the appearance of the obtained titanium chips is silvery white or light yellow , to avoid blue and purple peroxidized unqualified titanium chips; before rough slab processing, the milling machine workbench and titanium chip collection conveyor belt should be inspected and cleaned to avoid oil stains and foreign matter adh...

Embodiment 2

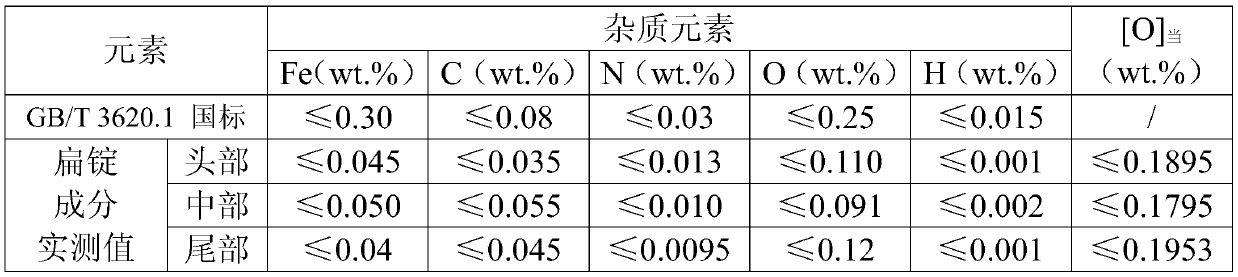

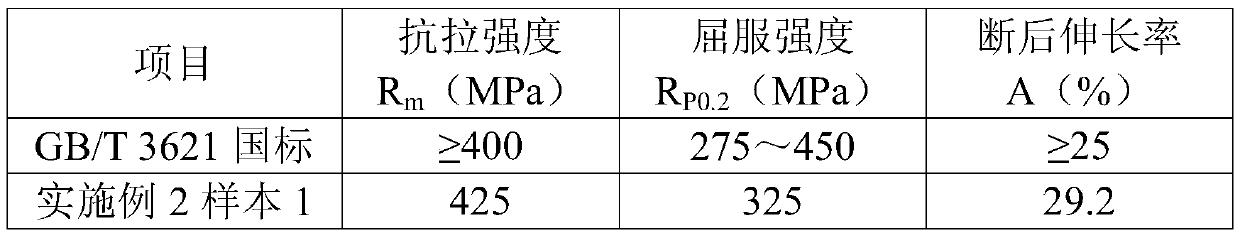

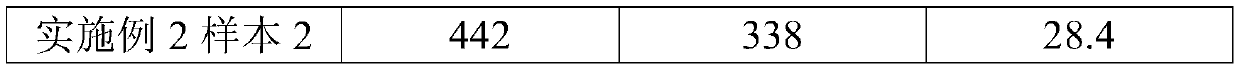

[0047] (1) The TA1 pure titanium rough slab whose surface is dry, clean, and free from oil stains, water stains, sundries and other foreign matter is dry-milled with a milling machine, and the milling cutter head is cooled by blowing compressed air without using coolant. To avoid contamination of titanium shavings, the feed rate of the milling cutter head is 4mm at a time, and the feed rate of the milling machine table is 100mm / min. The surface is machined to obtain TA1 pure titanium finished slabs and clean, silvery white and light yellow shavings of titanium residues. Material; wherein, TA1 pure titanium rough slab Fe, C, N, O impurity element content (mass percentage) is respectively 0.025%, 0.02%, 0.005%, 0.045%, impurity element overall content [O] 当 =[O]%+0.5×[Fe]%+0.7×[C]%+2.5×[N]%=0.045%+0.5×0.025%+0.7×0.02%+2.5×0.005%=0.084%; Before billet processing, check and clean the milling machine table and titanium chip collection conveyor belt to avoid oil stains and foreign m...

Embodiment 3

[0060] (1) The TA1 pure titanium rough slab whose surface is dry, clean, and free from oil stains, water stains, sundries and other foreign matter is dry-milled with a milling machine, and the milling cutter head is cooled by blowing compressed air without using coolant. To avoid contamination of titanium shavings, the feed rate of the milling cutter head is 2 mm at a time, and the feed speed of the milling machine table is 80 mm / min. The surface is machined to obtain TA1 pure titanium finished slabs and clean, silvery white and light yellow shavings of titanium residues. Material; wherein, TA1 pure titanium rough slab Fe, C, N, O impurity element content (mass percentage) is respectively 0.045%, 0.035%, 0.007%, 0.075%, impurity element overall content [O] 当 =[O]%+0.5×[Fe]%+0.7×[C]%+2.5×[N]%=0.075%+0.5×0.045%+0.7×0.035%+2.5×0.007%=0.1395; rough slab Before processing, check and clean the worktable of the milling machine and the titanium chip collection conveyor belt to avoid o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com