Epoxy resin plastic insulation sealing cover

An epoxy resin and plastic insulation technology, which is applied in the direction of insulators, engine seals, threaded fasteners, etc., can solve the problems of easy short circuit in the circuit, aggravate the corrosion of conductive parts, shorten the service life of high-voltage switchgear, etc., and achieve excellent Mechanical properties, prevention of phase-to-phase short circuit or external discharge, and the effect of protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

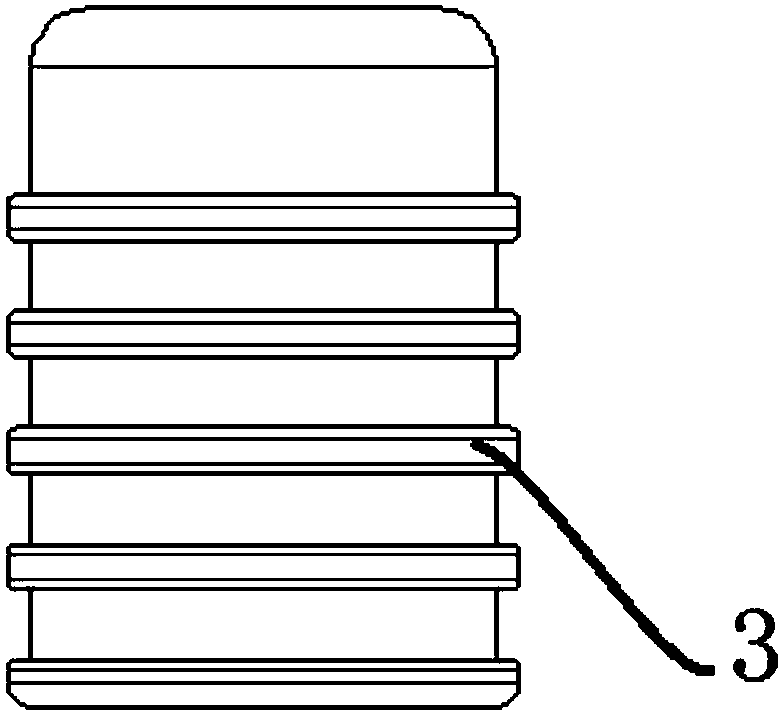

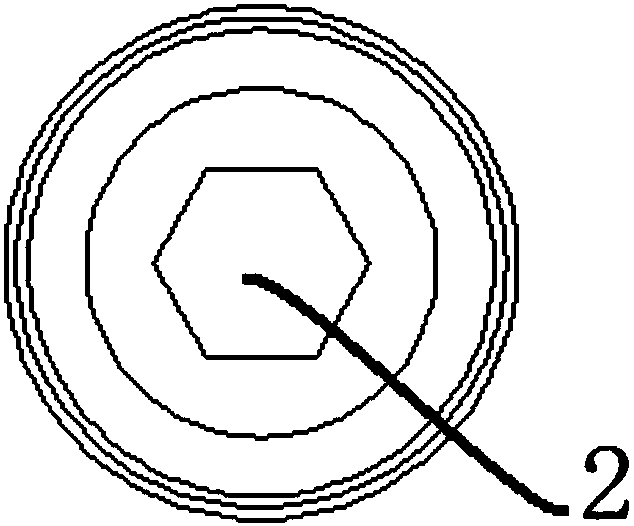

[0024] like Figure 1 to Figure 4 As shown, the present invention is an epoxy resin plastic insulating sealing cover, the sealing cover is a cylinder, one end surface of the sealing cover is provided with a circular blind hole 1, and the other end surface of the sealing cover is provided with a mounting hole 2. When the sealing cover blocks the main circuit of the high-voltage switchgear, it often blocks the connection part of the main circuit of the high-voltage switchgear. The connection part of the main circuit of the high-voltage switchgear is provided with a mounting hole for installing the sealing cover. In the installation hole of the main circuit of the high-voltage switchgear, the sealing cover isolates the conductive parts of the main circuit from the outside, and improves the insulation of the high-voltage switchgear to the outside world. The installation hole 2 is to use professional tools to install the sealing cover, improve the efficiency of assembly, and reduce...

Embodiment approach

[0027] In a preferred embodiment, the sealing cover is an epoxy insulating material. Epoxy resin is an excellent insulating material with high dielectric properties, surface leakage resistance, and arc resistance because its cured epoxy resin system has excellent insulating properties. The cured epoxy resin system has excellent mechanical properties. It has stable structure and excellent mechanical properties; the epoxy resin system after curing of epoxy resin has excellent alkali resistance, acid resistance and solvent resistance, and is suitable for use in severely polluted and severely corrosive places.

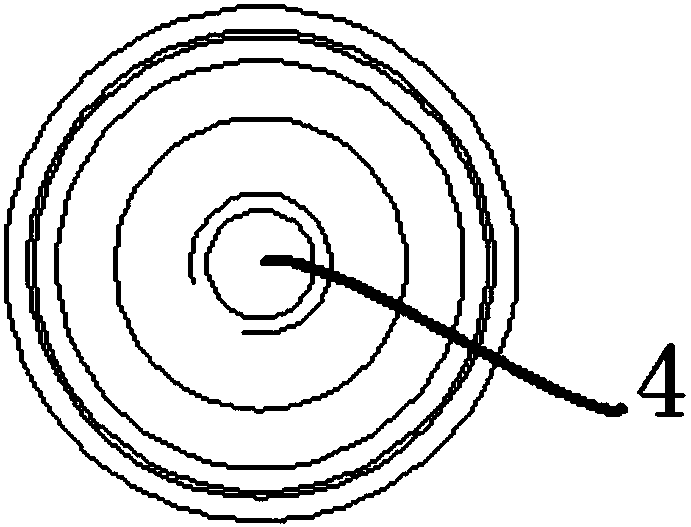

[0028] In a preferred embodiment, a threaded hole is provided inside the blind hole of the sealing cover, and the threaded hole is an insert nut 4 . The threaded hole is arranged inside the blind hole of the sealing cover to cooperate with a screw connecting the double-ended screw on the main busbar. The installation efficiency of the sealing cover. The insert nut 4 is n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com