Energy-saving ore dressing method for treating fine grained magnetite

A mineral processing method and fine-grained technology, which is applied in the energy-saving mineral processing field of processing fine-grained magnetite, can solve the problem that the magnetic iron-poor conjoined organisms cannot pass through multiple magnetic separations, the investment in fine grinding equipment is large, and the product quality is not good. Advanced problems, to achieve the effect of high grinding energy consumption and cost, saving grinding energy consumption, and increasing the coarse grinding fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Iron minerals in the ore processed in this embodiment are mainly magnetite, followed by siderite, and a small amount of specularite and limonite in addition; quartz is the most high content in the gangue minerals, followed by chlorite, Black hard chlorite and apatite, etc.; the particle size of magnetite in this ore is generally relatively uniform and fine, ranging from 0.01 to 0.2mm. The statistical results of the microscopic measurement of the embedded particle size of the magnetite show that the magnetite in the ore belongs to the category of relatively uniform fine-grained embedded distribution. From the point of view of embedded particle size alone, in order to dissociate more than 95% of the magnetite, it is necessary to choose a grinding fineness of -0.026mm (-600 mesh accounts for 95%).

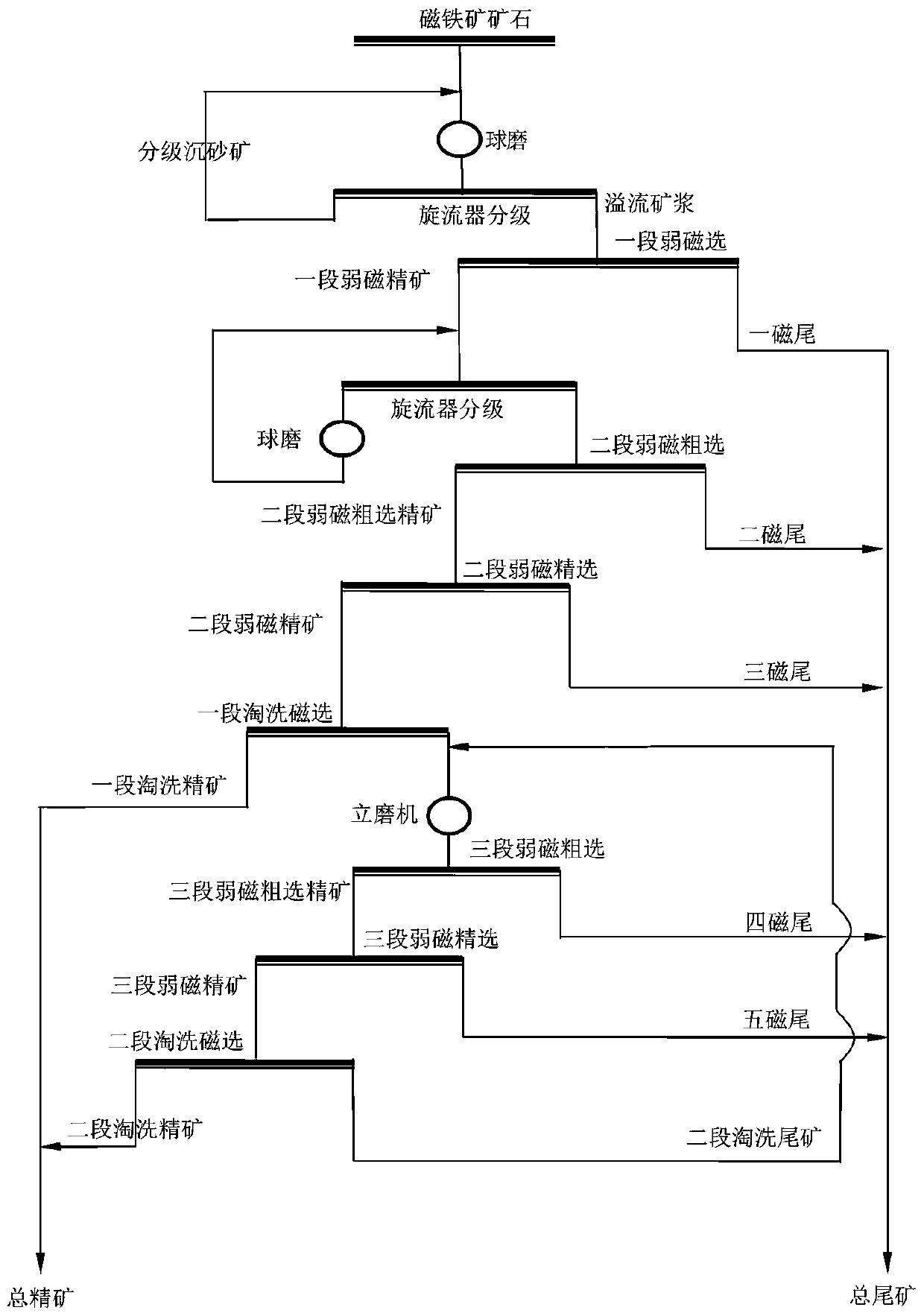

[0042] The energy-saving beneficiation method of processing fine magnetite of the present embodiment, its technological process is as follows figure 1 As shown, the specific p...

Embodiment 2

[0055] The main constituent mineral types in the ore processed in this embodiment are relatively simple. The iron minerals are mainly magnetite, followed by specularite; the gangue minerals are mainly quartz, followed by iron dolomite, sericite, and chlorite. stone, talc and tremolite. The magnetite in this ore is in the shape of euhedral and semi-euhedral equiaxed grains, and the crystal grain size is relatively small, except for a few that can reach about 0.2mm, generally below 0.06mm, and some are even smaller than 0.005mm; It is characterized by extremely uneven distribution of fine grains to fine grains. From the point of view of embedded particle size alone, in order to dissociate more than 95% of iron minerals, the grinding fineness of -0.038mm (-400 mesh) accounts for more than 95%.

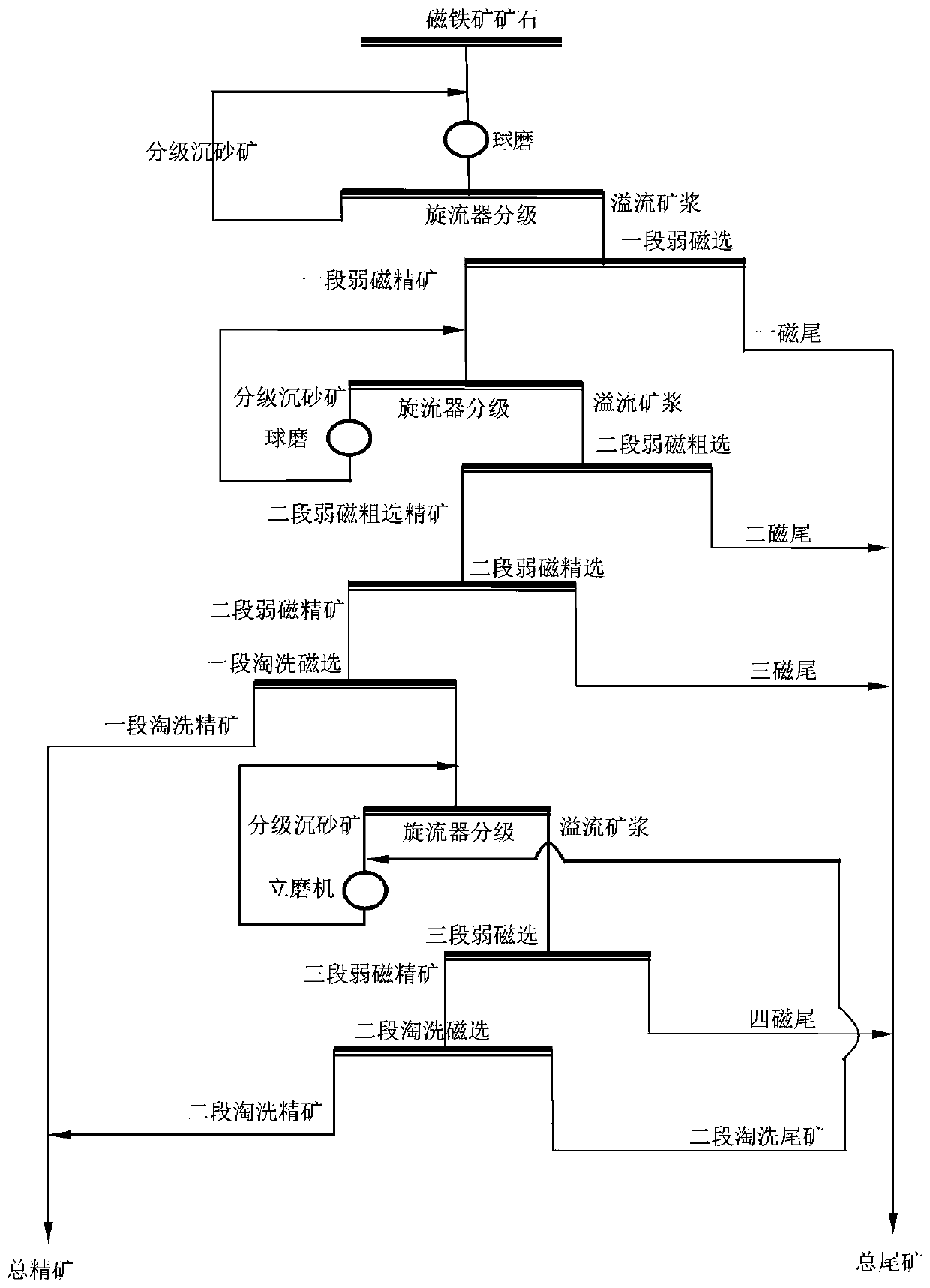

[0056] The energy-saving beneficiation method of processing fine magnetite of the present embodiment, its technological process is as follows figure 2 As shown, the specific process st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com