Sectional type pyrolysis and gasification device

A pyrolysis gasification, segmented technology, applied in the direction of gasification device feeding tools, gasification process, chemical industry, etc., can solve the problems of uneven air distribution of materials, high energy consumption, low biomass conversion rate, etc. , to achieve the effect of prolonging the reaction residence time, improving the pyrolysis efficiency, and uniform and stable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

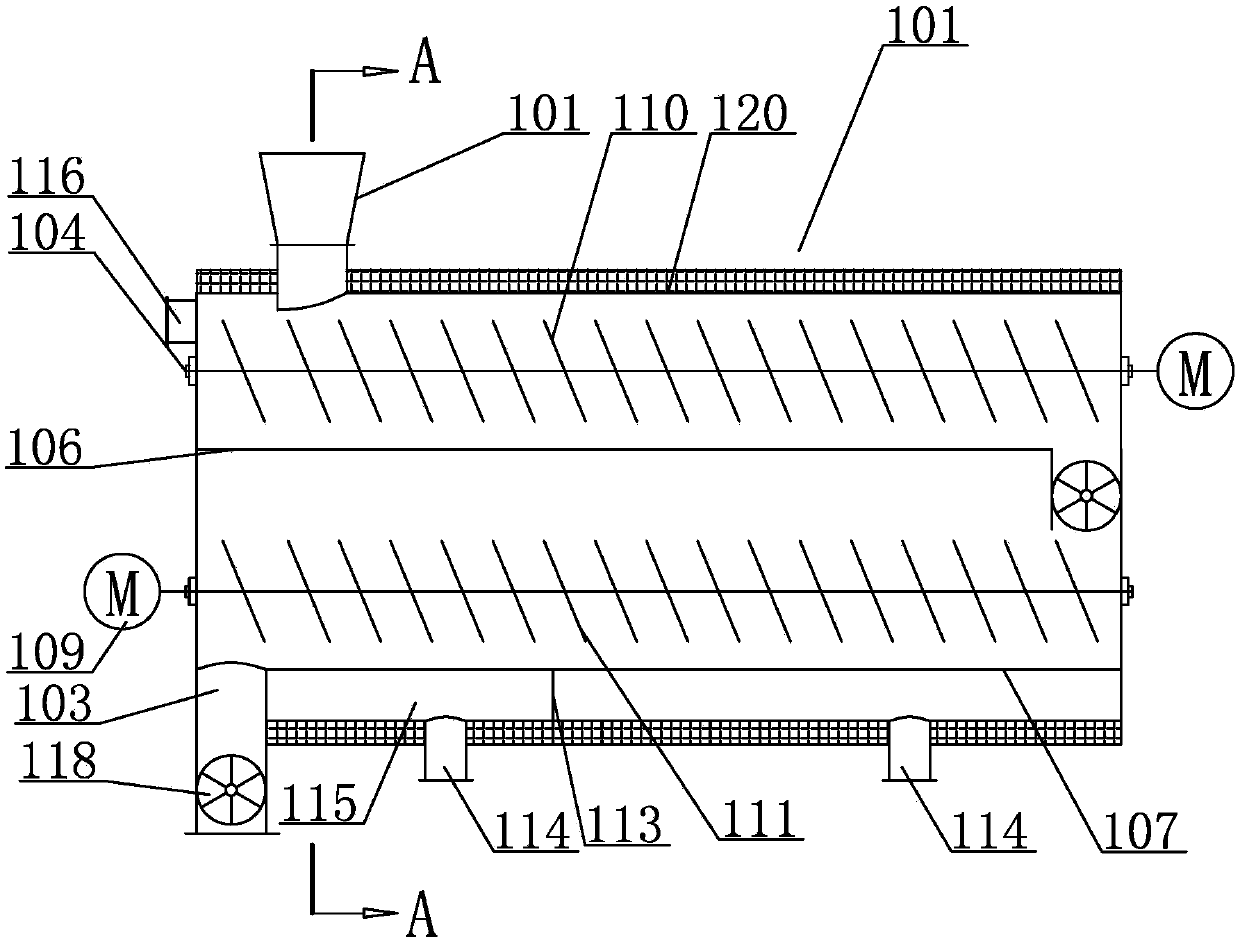

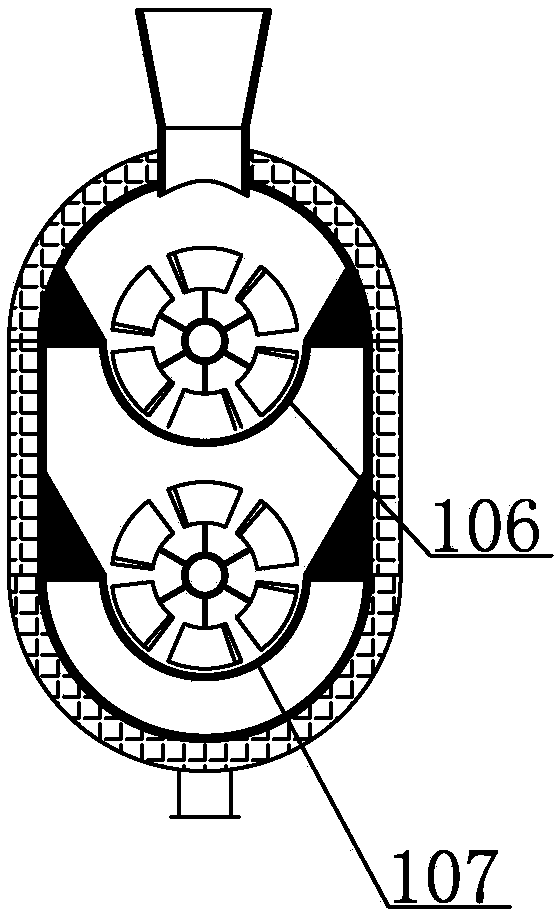

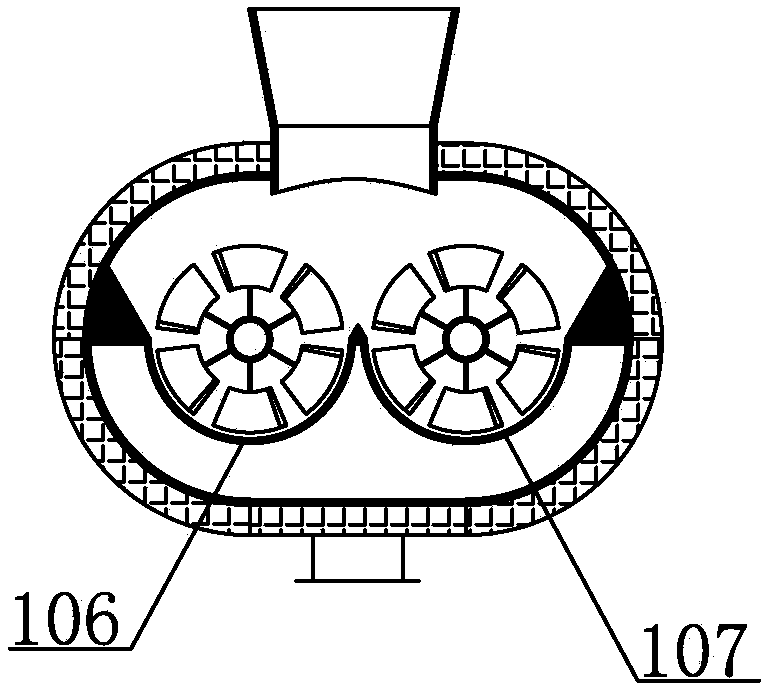

[0022] like Figure 1-5 As shown, a segmented pyrolysis gasification device includes a first furnace body 101, a first feed port 102 and a first discharge port 103 provided on the first furnace body 101, and a first furnace body Inside 101, there are two first main shafts 104 and second main shafts 105 that are spaced apart and cross the first furnace body 101, and a first trough-type air distribution plate 106 is provided below the first main shaft 104 and the second main shaft 105. and the second trough air distribution plate 107, the first drive governor 108 and the second drive governor 109 respectively provided on the first main shaft 104 and the second main shaft 105, the first main shaft 104 and the second main shaft 105 are respectively provided with a plurality of first blades 110 and second blades 111 distributed at equal intervals, a second outlet 112 provided on one side of the first trough-type air distribution plate 106, and a second trough-type air distribution ...

Embodiment 2

[0024] like Image 6 As shown, a segmented pyrolysis and gasification device includes three first spiral pyrolysis and gasification furnaces 210, second spiral pyrolysis and gasification furnaces 220 and third spiral pyrolysis and gasification furnaces 230 connected in series. . The first spiral pyrolysis gasification furnace 210 includes a second furnace body 211, a second feed port 212 and a third discharge port 213 provided on the second furnace body 211, and a horizontal Pass through the third main shaft 214 of the second furnace body 211, the third trough type air distribution plate 215 provided on the third main shaft 214, the third drive governor 216 provided on the third main shaft 214, The three main shafts 214 are provided with a plurality of third blades 217 distributed at equal intervals, and the second partition plate 218 and the corresponding third trough type air distribution plate 215 and the inner wall of the second furnace body 211 are provided between the t...

Embodiment 3

[0026] like Figure 7 As shown, the material enters the system from the feed port of the first spiral pyrolysis gasifier 210 in the reaction section, and is dried and pyrolyzed in the first spiral pyrolysis gasifier 210 in the reaction section, and the gas is heated by the first spiral pyrolysis gasifier in the reaction section. The second gas outlet 240 of the pyrolysis gasifier 210 is discharged, and in the second spiral pyrolysis gasifier 220 of the reaction section, the air entering through the third gasification agent inlet 229 is mixed with the air from the first spiral pyrolysis gasifier 210 of the reaction section. The material in the third discharge port 213 undergoes a gasification reaction to generate gas and release heat, which is used to maintain the high temperature environment of the second spiral pyrolysis gasifier 220 in the reaction section. The gas outlet of the furnace 220 is discharged and enters the first spiral pyrolysis gasifier 210 in the reaction sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com