Preparation method of strong base type ion exchanging fibers

A technology for exchanging fibers and alkali ions, which is applied in the field of preparation of ion exchange fibers to achieve the effects of convenient operation, maturity and stability, and simple reaction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of strong base ion exchange fiber of the present invention, the detailed steps of this preparation method are as follows:

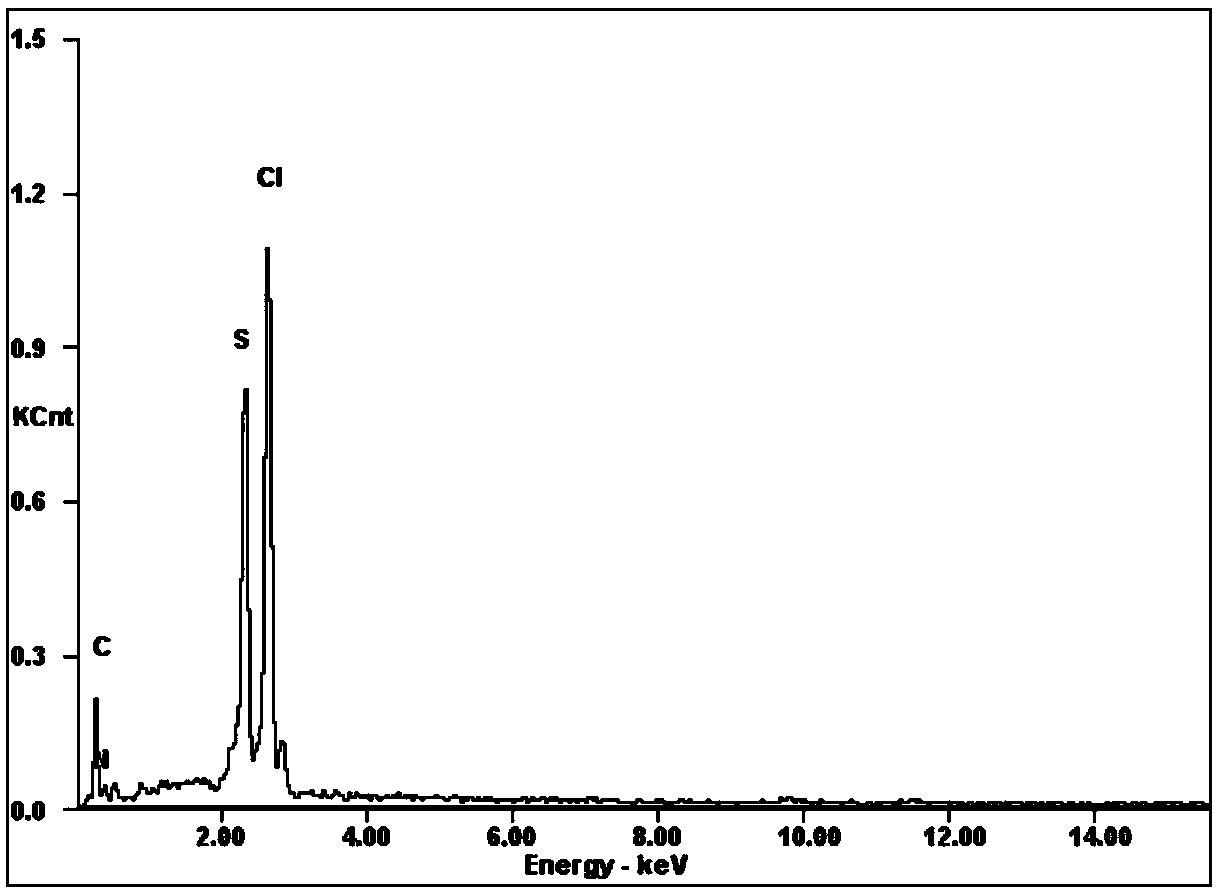

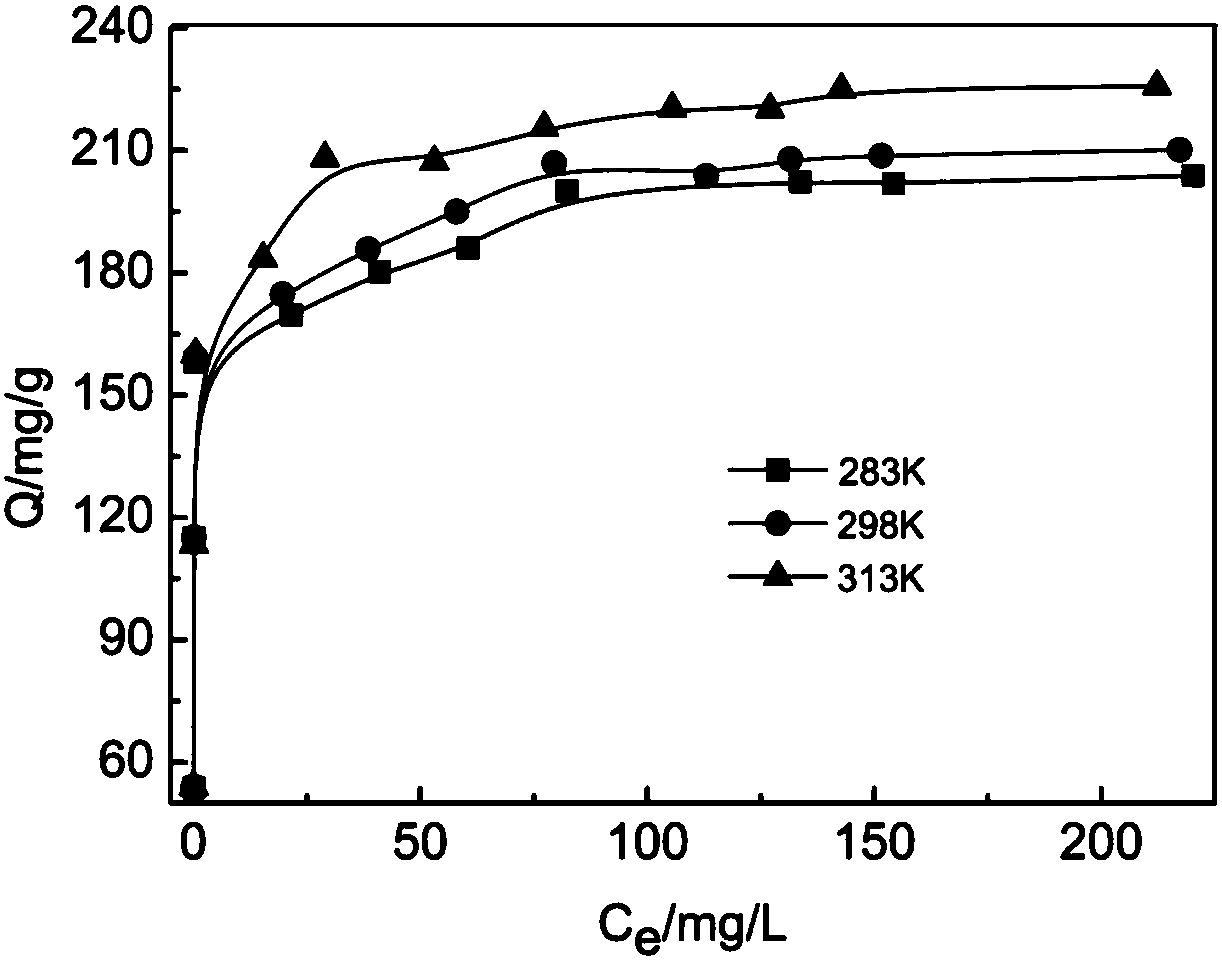

[0038]a. First weigh 1.84g of polyphenylene sulfide fiber, that is, PPS fiber, and add it to the reaction bottle, then add 18.4ml of dichloroethane and let it stand for swelling for 48h. After swelling, add 0.92g (5mmol) cyanuric chloride and 1.305g (5mmol) ) anhydrous tin tetrachloride and stir evenly, then heat up to 60°C, and react for 48h under this temperature condition; Soak in HCl for 10 hours, extract with ethanol for 8 hours, wash with water until neutral, and dry in vacuum to constant weight (vacuum degree is 0.08Mpa, drying temperature is 60°C, drying time is 24 hours), and after drying, polyphenylene modified with cyanuric chloride is obtained. Sulfide fiber (relative to the original polyphenylene sulfide fiber, the weight gain of the modified fiber is 23%; after calculation, the amount of grafted cyanuric chlorid...

Embodiment 2

[0041] The preparation method of strong base ion exchange fiber of the present invention, the detailed steps of this preparation method are as follows:

[0042] a. First weigh 4.6g of PP-St-DVB fiber and add it to the reaction flask, then add 200ml of nitrobenzene and let it stand for swelling for 12h. After swelling, add 11.5g (62.5mmol) of cyanuric chloride and 10.14g (62.5mmol) of Ferric trichloride in water is ultrasonically dissolved, then heated to 120°C, and reacted at this temperature for 6 hours; after the reaction, cool to room temperature, filter, and filter out the obtained product, which is sequentially used with a concentration of 2mol / L Soak in HCl for 10 hours, extract with ethanol for 8 hours, wash with water to neutrality, and vacuum-dry to constant weight (vacuum degree is 0.08Mpa, drying temperature is 60°C, drying time is 24 hours), and after drying, PP-St modified by cyanuric chloride is obtained. -DVB fiber (compared to the original PP-St-DVB fiber, the ...

Embodiment 3

[0046] The preparation method of strong base ion exchange fiber of the present invention, the detailed steps of this preparation method are as follows:

[0047] a. First weigh 0.92g of PP-St-DVB fiber into the reaction bottle, then add 20ml of chloroform and let it stand for swelling for 6h, after swelling, add 2.76g (15mmol) of cyanuric chloride and 0.1g (7.5mmol) of anhydrous Aluminum trichloride is ultrasonically dissolved, then heated up to 60°C, and reacted at this temperature for 24 hours; after the reaction, cool to room temperature, filter, and filter out the obtained product, which is sequentially treated with HCl with a concentration of 2mol / L Soak for 10 hours, extract with ethanol for 8 hours, wash with water until neutral, and vacuum-dry to constant weight (vacuum degree is 0.08Mpa, drying temperature is 60°C, drying time is 24 hours), and after drying, PP-St- DVB fiber (compared to the original PP-St-DVB fiber, the weight gain of the modified fiber is 39%; after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com