Model construction method for wood softening effect after hydro-thermal-microwave combined softening treatment

A technology of softening treatment and construction method, applied in radiation/wave wood treatment, wood treatment, wood heating and other directions, can solve the problems of different softening conditions and inapplicability, achieve strong equipment versatility, achieve quantitative control, and adapt to tree species wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

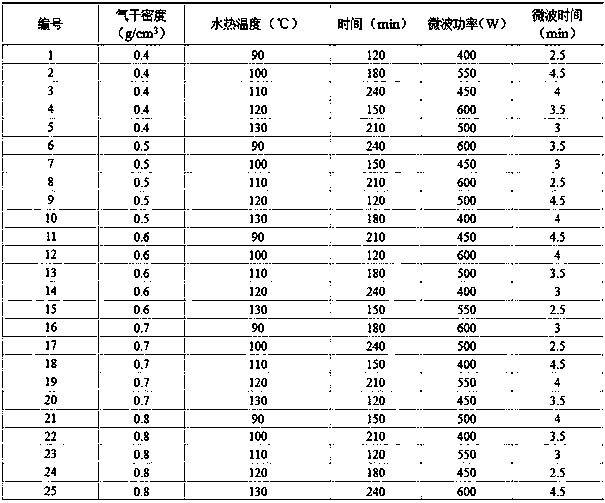

[0036] Experimental materials and methods:

[0037] A Hydrothermal softening treatment:

[0038] 1) Sample tree species: white wood, artificial forest teak, Chinese toon, natural forest teak, water Qinggang; different densities of wood have white wood ( Aquilaria sinensis ) (air dry density 0.40g / cm 3 ), plantation teak ( Tectona grandis ) (air dry density 0.50g / cm 3 ), Toon ( Toona sinensis ) (air dry density 0.60g / cm 3 ), natural forest teak (air dry density 0.70g / cm 3 ), Shuiqinggang ( Fagus longipetiolata ) (air dry density 0.80g / cm 3 );

[0039] 2) Sample size: the length direction, that is, the axial direction of the wood sample is 30 mm, the width direction, that is, the chord direction of the wood sample is 20 mm, and the thickness direction, that is, the radial direction of the wood sample is 20 mm.

[0040] 3) Wood initial moisture content: 10%

[0041] 4) Absolute pressure: 0.01-0.02MPa

[0042] 5) Treatment temperature: 90~120℃, treatment time 120~24...

Embodiment 2

[0076] A method for building a model of wood softening effect after hydrothermal-microwave joint softening treatment, comprising the following specific steps:

[0077] A. Hydrothermal softening treatment: for different densities x 1 (0.2-1.0 g / cm 3 ) wood undergoes hydrothermal softening treatment, the temperature of the hydrothermal softening treatment is x 2 (70-150°C), water heating time is x 3 (80-200min) to obtain wood softened by hydrothermal treatment; the size of the wood is 30mm in the axial direction, 10mm in the chord direction, and 10mm in the radial direction;

[0078] B, get the wood processed through step A, use 2 layers of polyvinyl chloride film to wrap the wood, and then carry out microwave softening treatment, the power of the microwave softening treatment is x 4 (400-800 W), microwave time is x 5 (1-6min), to obtain the wood after combined softening treatment by hydrothermal-microwave;

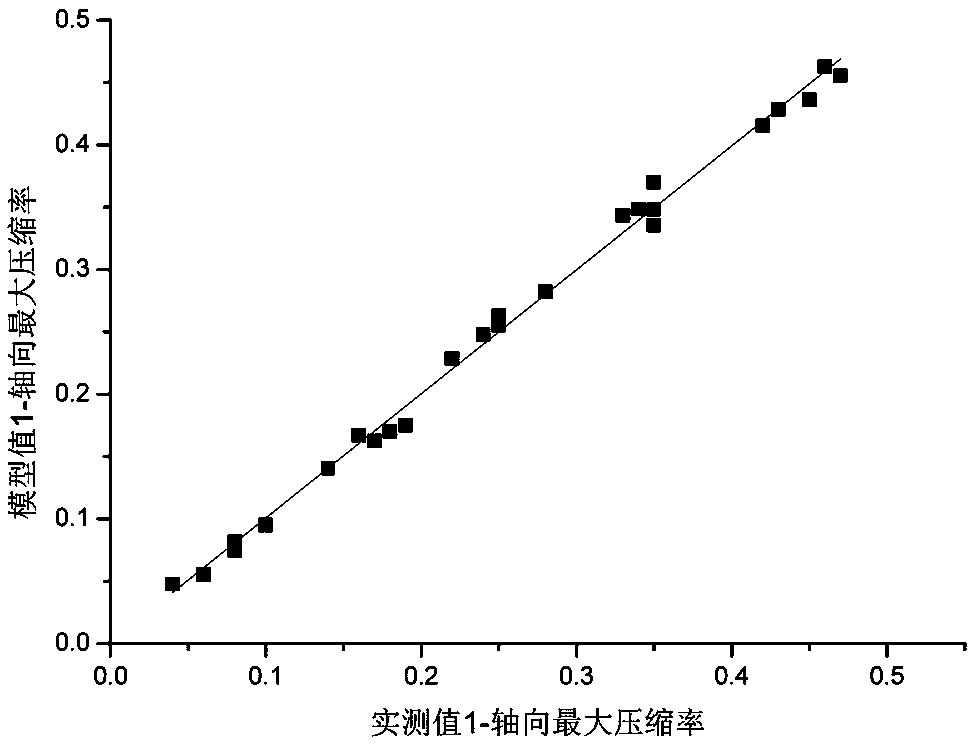

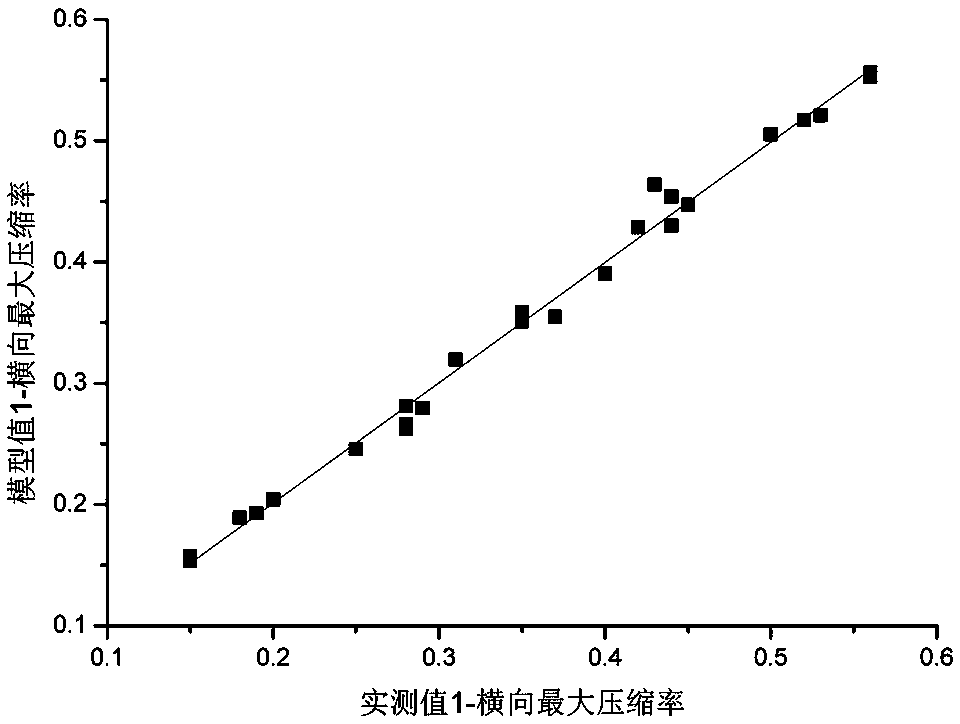

[0079] C, model building: carry out transverse compression t...

Embodiment 3

[0087] A method for building a model of wood softening effect after hydrothermal-microwave joint softening treatment, comprising the following specific steps:

[0088] A. Hydrothermal softening treatment: for different densities x 1 (0.2-1.0 g / cm 3 ) wood undergoes hydrothermal softening treatment, the temperature of the hydrothermal softening treatment is x 2 (70-150°C), water heating time is x 3 (80-200min) to obtain wood softened by hydrothermal treatment; the size of the wood is 3mm in the axial direction, 30mm in the chord direction, and 30mm in the radial direction;

[0089] B, get the timber processed through step A, adopt 10 layers of polyvinyl chloride film to wrap the timber, then carry out microwave softening treatment, the power of described microwave softening treatment is x 4 (400-800 W), microwave time is x 5 (1-6min), to obtain the wood after combined softening treatment by hydrothermal-microwave;

[0090] C, model building: carry out transverse compr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com