Hexamethylene tetramine salt anion-exchange membrane and preparation method thereof

A technology of hexamethylene tetramine salt and anion exchange membrane is applied in the field of anion exchange membrane based on hexamethylene tetramine salt and its preparation, which can solve the problem of hindering the commercial application of anion exchange membrane, low thermal and chemical stability , affecting battery performance and other issues, to achieve the effect of simple and easy preparation method, good mechanical properties and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

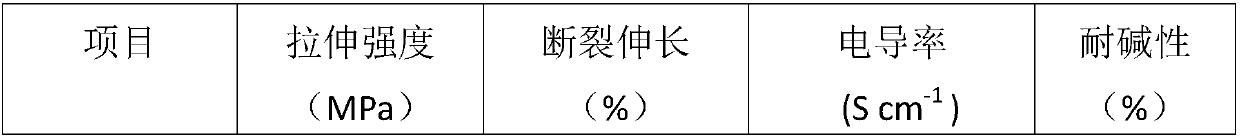

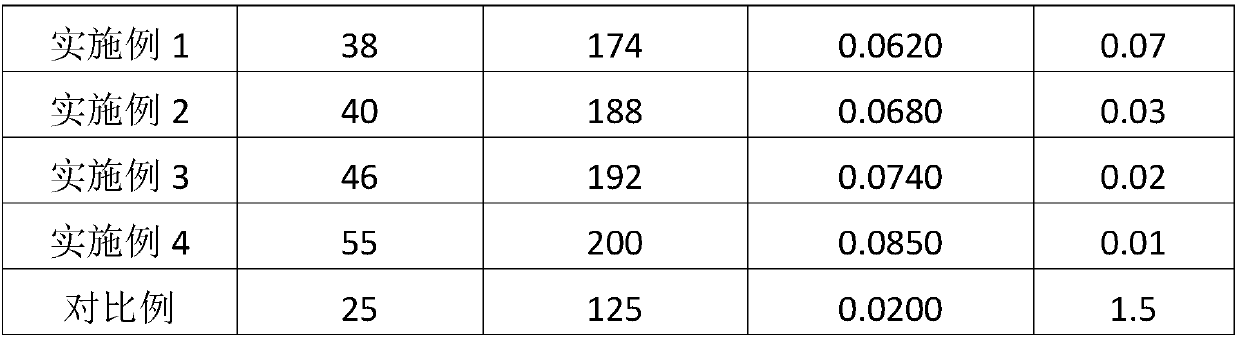

Examples

Embodiment 1

[0027] A preparation method based on hexamethylenetetramine salt anion exchange membrane, comprising the steps of:

[0028] 1) Preparation of epoxy-substituted hexamethylenetetramine salt: 10 g of hexamethylenetetramine and 27 g of epichlorohydrin were dissolved in 90 g of ethanol, and after reflux reaction at 40° C. for 6 hours, spin at 50° C. Remove the solvent by evaporation, wash with a mixed solvent for 3 times, and then remove the solvent by rotary evaporation at 50°C; the mixed solvent is a mixture formed by mixing ethanol and ether in a mass ratio of 3:7;

[0029] 2) Preparation of base film: 3 g of epoxy-substituted hexamethylenetetramine salt and 10 g of polyurethane prepared in step 1) were dissolved in 30 g of dimethyl sulfoxide, stirred and reacted at 70° C. for 6 hours, and then Precipitated in acetone, filtered, washed with water and ethanol three times respectively, and dried in a vacuum oven at 60°C for 12 hours;

Embodiment 2

[0034] A preparation method based on hexamethylenetetramine salt anion exchange membrane, comprising the steps of:

[0035] 1) Preparation of epoxy-substituted hexamethylenetetramine salt: 10 g of hexamethylenetetramine and 28 g of epichlorohydrin were dissolved in 100 g of chloroform, and after reflux reaction at 45° C. for 7 hours, spin at 55° C. Remove the solvent by evaporation, wash with a mixed solvent for 4 times, and then remove the solvent by rotary evaporation at 55°C; the mixed solvent is a mixture formed by mixing ethanol and ether in a mass ratio of 4:7;

[0036] 2) Preparation of base film: dissolve 3.3 g of epoxy-substituted hexamethylenetetramine salt and 10 g of polyurethane in 35 g of N-methylpyrrolidone prepared in step 1), and stir and react at 74°C for 7 hours , precipitated in acetone, filtered, washed with water and ethanol for 4 times respectively, and dried in a vacuum oven at 70°C for 14 hours;

[0037] 3) Ion exchange: soak the polymer film prepared...

Embodiment 3

[0041] A preparation method based on hexamethylenetetramine salt anion exchange membrane, comprising the steps of:

[0042] 1) Preparation of epoxy-substituted hexamethylenetetramine salt: 10 g of hexamethylenetetramine and 29 g of epichlorohydrin were dissolved in 120 g of carbon tetrachloride, and after reflux reaction at 52° C. for 8 hours, at 57 The solvent was removed by rotary evaporation at ℃, and then washed 5 times with a mixed solvent, and then the solvent was removed by rotary evaporation at 58 °C; the mixed solvent was a mixture formed by mixing ethanol and ether in a mass ratio of 3.5:7;

[0043] 2) Preparation of base film: dissolve 3.7g of epoxy-substituted hexamethylenetetramine salt and 10g of polyurethane in 37g of N,N-dimethylformamide prepared in step 1), and stir at 77°C After reacting for 8 hours, it was precipitated in acetone, filtered, washed with water and ethanol for 5 times respectively, and then baked in a vacuum oven at 76°C for 17 hours;

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com