Gibbsite-type bauxite two-stream digestion process unit and method thereof

A technology of gibbsite type and process equipment, which is applied in chemical instruments and methods, preparation of alkali metal aluminate/alumina/aluminum hydroxide, aluminum compounds, etc. Maintenance, poor separation effect and other problems, to achieve the effect of easy operation and maintenance, reduced operating costs, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

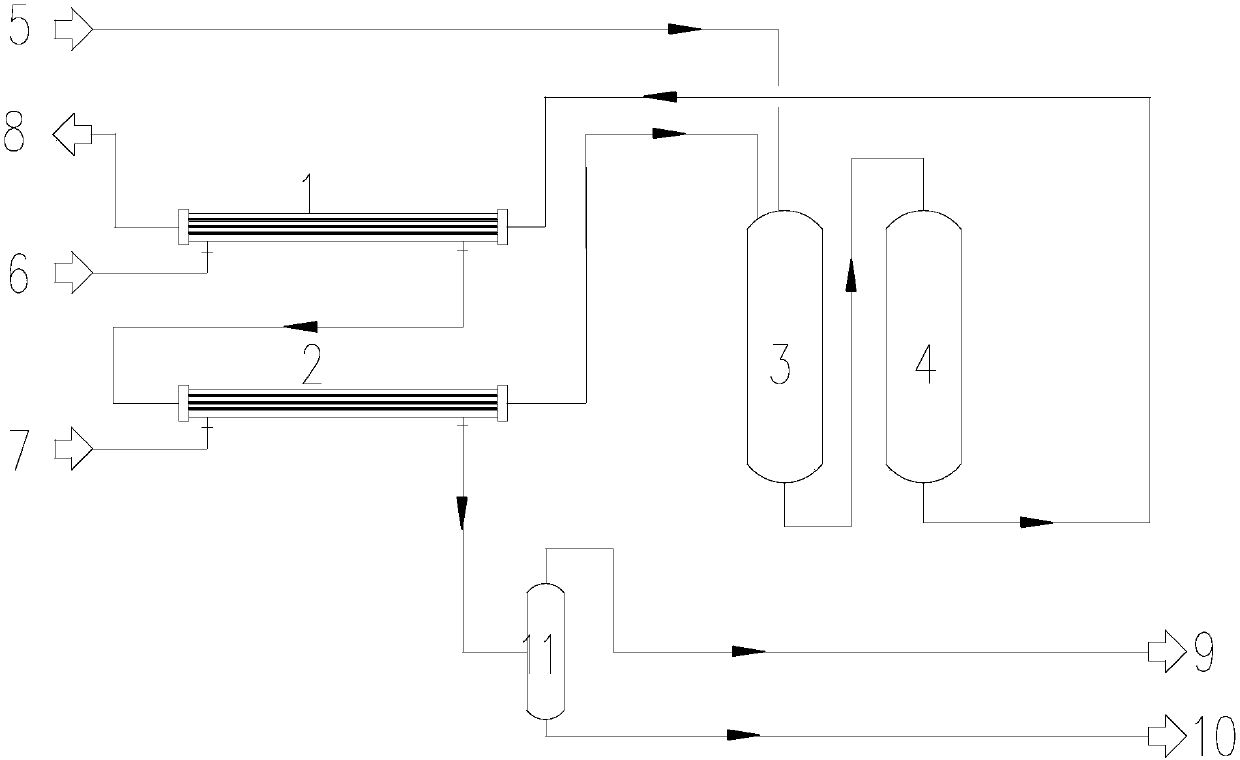

[0054] A process device for gibbsite-type bauxite double-flow method dissolution, its connection diagram is shown in figure 1 , the process device includes a preheater 1, a heater 2, a mixing device 3, a stripping reaction device 4 and a fresh steam condensate tank 11;

[0055]Wherein, the shell-side feed inlet of the preheater 1 is connected to the circulating mother liquid 6 pipeline, the shell-side discharge port of the preheater 1 is connected to the heater 2 tube side, and the heater 2 tube side is connected to the mixing device in turn. 3. The dissolution reaction device 4 is connected in sequence, and the outlet of the dissolution reaction device 4 is connected to the tube side of the preheater 1;

[0056] Described mixing device 3 is connected with raw ore slurry 5 pipelines;

[0057] The shell-side feed port of the heater 2 is connected with the high-pressure fresh steam 7 pipeline, and the shell-side discharge port of the heater 2 is connected with the live steam co...

Embodiment 2

[0071] A process device for gibbsite-type bauxite double-flow method dissolution, its connection diagram is shown in Figure 5 , the process device includes a preheater 1, a heater 2, a mixing device 3, a stripping reaction device 4 and a fresh steam condensate tank 11;

[0072] Wherein, the shell-side feed inlet of the preheater 1 is connected to the circulating mother liquid 6 pipeline, the shell-side discharge port of the preheater 1 is connected to the heater 2 tube side, and the heater 2 tube side is connected to the mixing device in turn. 3. The dissolution reaction device 4 is connected in sequence, and the outlet of the dissolution reaction device 4 is connected to the tube side of the preheater 1;

[0073] Described mixing device 3 is connected with raw ore slurry 5 pipelines;

[0074] The shell-side feed port of the heater 2 is connected with the high-pressure fresh steam 7 pipeline, and the shell-side discharge port of the heater 2 is connected with the live steam ...

Embodiment 3

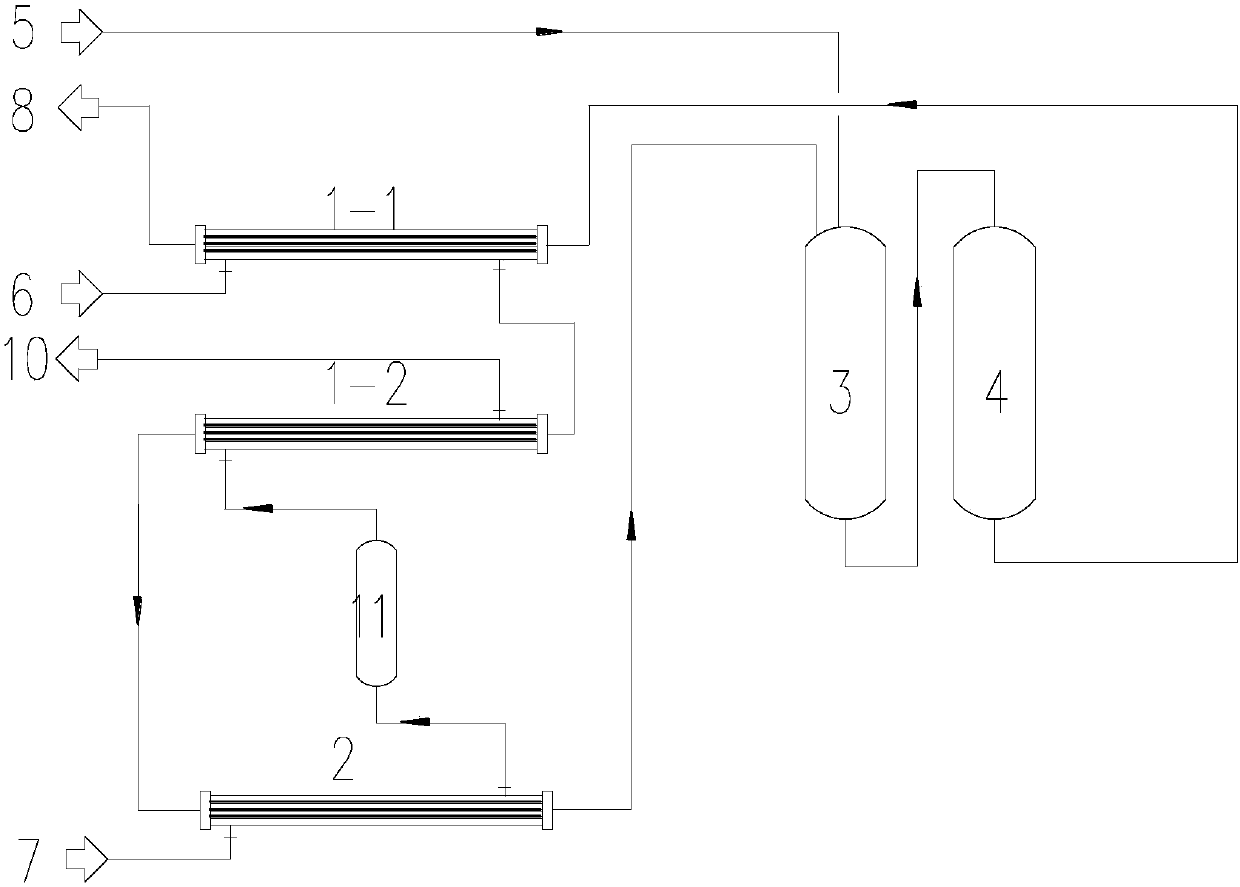

[0087] A process device for gibbsite-type bauxite double-flow method dissolution, its connection diagram is shown in image 3 , the process unit comprises a first preheater 1-1, a second preheater 1-2, a heater 2, a mixing device 3, a stripping reaction device 4 and a new steam condensed water tank 11;

[0088] Wherein, the shell-side feed port of the first preheater 1-1 is connected with the circulation mother liquid 6 pipeline, and the shell-side discharge port of the first preheater 1-1 is connected with the second preheater 1-2 The tube side is connected, and then connected to the heater 2 tube side, and the heater 2 tube side is connected to the mixing device 3 and the dissolution reaction device 4 in sequence, and the discharge port of the dissolution reaction device 4 is connected to the first preheater 1-1 tube connection;

[0089] Described mixing device 3 is connected with raw ore slurry 5 pipelines;

[0090] The shell-side feed inlet of the heater 2 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com