Jet-based micro-bubble generation method and jet micro-bubble aerator

A method for generating microbubbles, applied in water aeration, chemical instruments and methods, sustainable biological treatment, etc., can solve the problems of large bubble volume, low oxygen utilization rate, poor mixing uniformity, etc., to increase the total contact area, increase the contact area, and reduce the effect of the bubble diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1. Use environment and parameters

[0056] This application example is a jet microbubble aerator for sewage treatment, in which the volume flow of sewage is: 13m 3 / h, according to the relevant requirements of sewage treatment, the gas-liquid volume flow ratio is 0.1.

[0057] 2. Program introduction

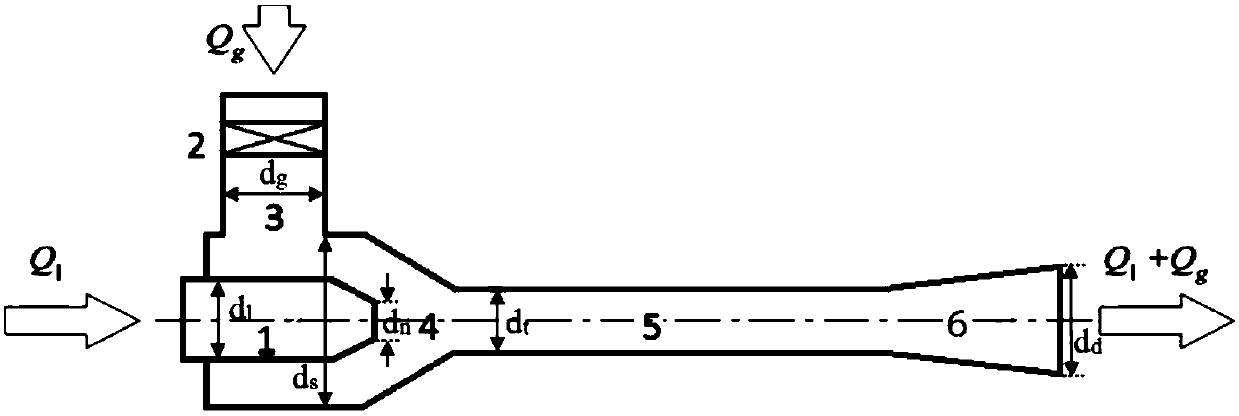

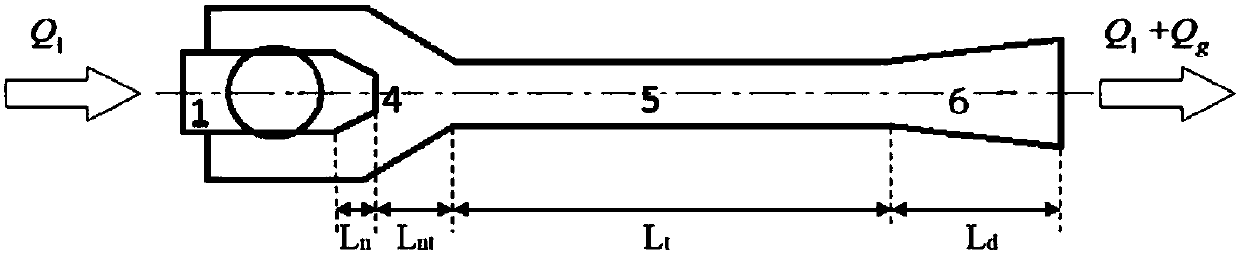

[0058] combine Figure 5 and Figure 6 , the jet microbubble aeration device designed according to the prior art, its design parameters closely related to the present invention are: inlet pipe diameter where Q l is the liquid flow rate, u l1 Design flow rate for liquid; nozzle diameter Where φ is the nozzle velocity coefficient, P l is the liquid flow rate, ρ is the fluid density; the shrinkage length of the nozzle of the water inlet pipe L n =a n (d l -d n ), where a n is the nozzle contraction length coefficient; the diameter of the intake pipe Where q is the gas-liquid flow ratio, u g2 Design flow rate for gas; suction chamber diameter d s =a ds d l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com