Olefin polymerization catalyst support, preparation method, catalyst component for olefin polymerization, olefin polymerization catalyst and applications of olefin polymerization catalyst support, catalyst component for olefin polymerization and olefin polymerization catalyst

A technology for catalyst carrier and olefin polymerization, which is applied in olefin polymerization catalyst carrier and its preparation, olefin polymerization catalyst components, olefin polymerization catalyst and their application fields, and can solve the problems of increasing post-recycling processing cost, increasing cost, and recycling and processing of by-products To achieve the effect of good particle shape, improved bulk density and isotacticity, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0042] According to a preferred embodiment of the present invention, the average particle diameter of the olefin polymerization catalyst carrier may be 10-100 microns, preferably 20-90 microns, and the particle size distribution is less than 1.2, preferably 0.7-0.9. In this preferred embodiment, the catalyst prepared from the olefin polymerization catalyst support is capable of yielding olefin polymers with higher bulk density. In the present invention, the average particle diameter and particle size distribution of the olefin polymerization catalyst carrier can be measured by using a Master Sizer 2000 laser particle size analyzer (manufactured by Malvern Instruments Ltd).

[0043] According to the present invention, the olefin polymerization catalyst carrier may also carry a trace amount of water, and the water comes from the trace amount of water carried by the synthesis raw material and the reaction medium.

[0044]According to the present invention, the synthetic raw mater...

preparation example 1

[0103] This preparation example is used to illustrate the olefin polymerization catalyst carrier provided by the present invention and its preparation method.

[0104] In a 0.6L reactor, add 0.07mol magnesium chloride, 0.007mol magnesium bromide, and 0.96mol ethanol, and raise the temperature to 90°C while stirring. Constant temperature reaction for 2 hours. The mixture was stirred at a low speed (400 rpm) to disperse for 30 minutes for emulsification. Add 0.48 mol of epichlorohydrin to the emulsified product, react for half an hour, press filter, wash the press filter product 5 times with hexane, and vacuum dry to obtain catalyst carrier Z1 for olefin polymerization.

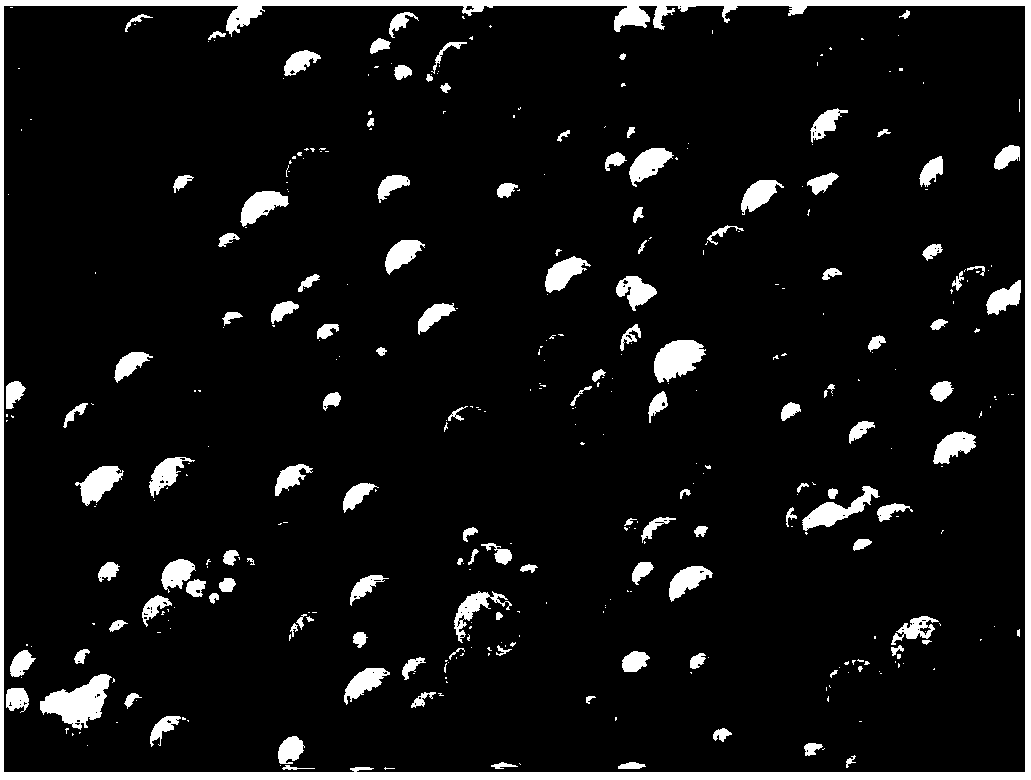

[0105] Characterized by nuclear magnetic resonance and elemental analysis, the structural formula of the obtained catalyst support Z1 is as follows:

[0106]

[0107] The average particle diameter (D50) of the olefin polymerization catalyst carrier Z1 is 51 microns, and the particle size distribution ((D90...

preparation example 2

[0109] This preparation example is used to illustrate the olefin polymerization catalyst carrier provided by the present invention and its preparation method.

[0110] In a 0.6L reactor, add 300mL of white oil, 0.07mol of magnesium chloride, 0.005mol of magnesium bromide, and 0.48mol of ethanol, raise the temperature to 100°C with stirring, and react at constant temperature for 1 hour. The mixture was stirred at a low speed (600 rpm) to disperse for 30 minutes for emulsification. And add 0.45 mol of epichlorohydrin to the emulsified product, react for 20 minutes, press filter, wash the press filter product with hexane for 5 times, and finally vacuum dry the product to obtain olefin polymerization catalyst carrier Z2.

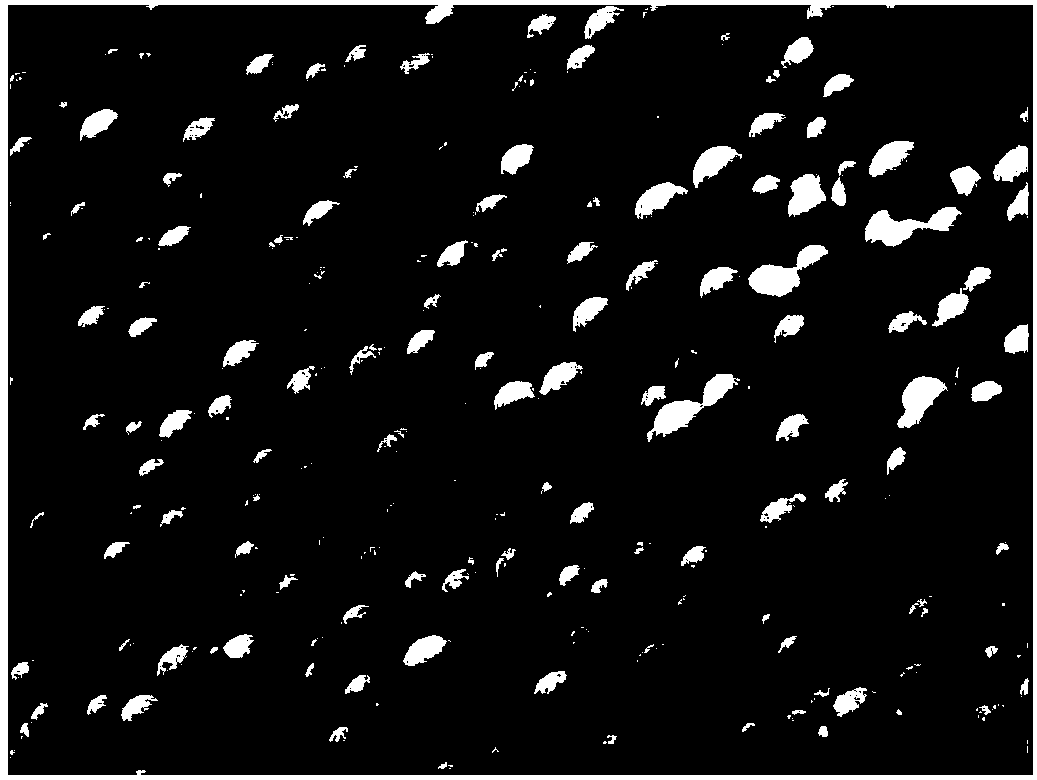

[0111] Characterized by nuclear magnetic resonance and elemental analysis, the structural formula of the obtained catalyst support Z2 is as follows:

[0112]

[0113] The average particle diameter (D50) of the olefin polymerization catalyst carrier Z2 is 56 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com