Flexible conductive super-hydrophobic coating and preparation method thereof

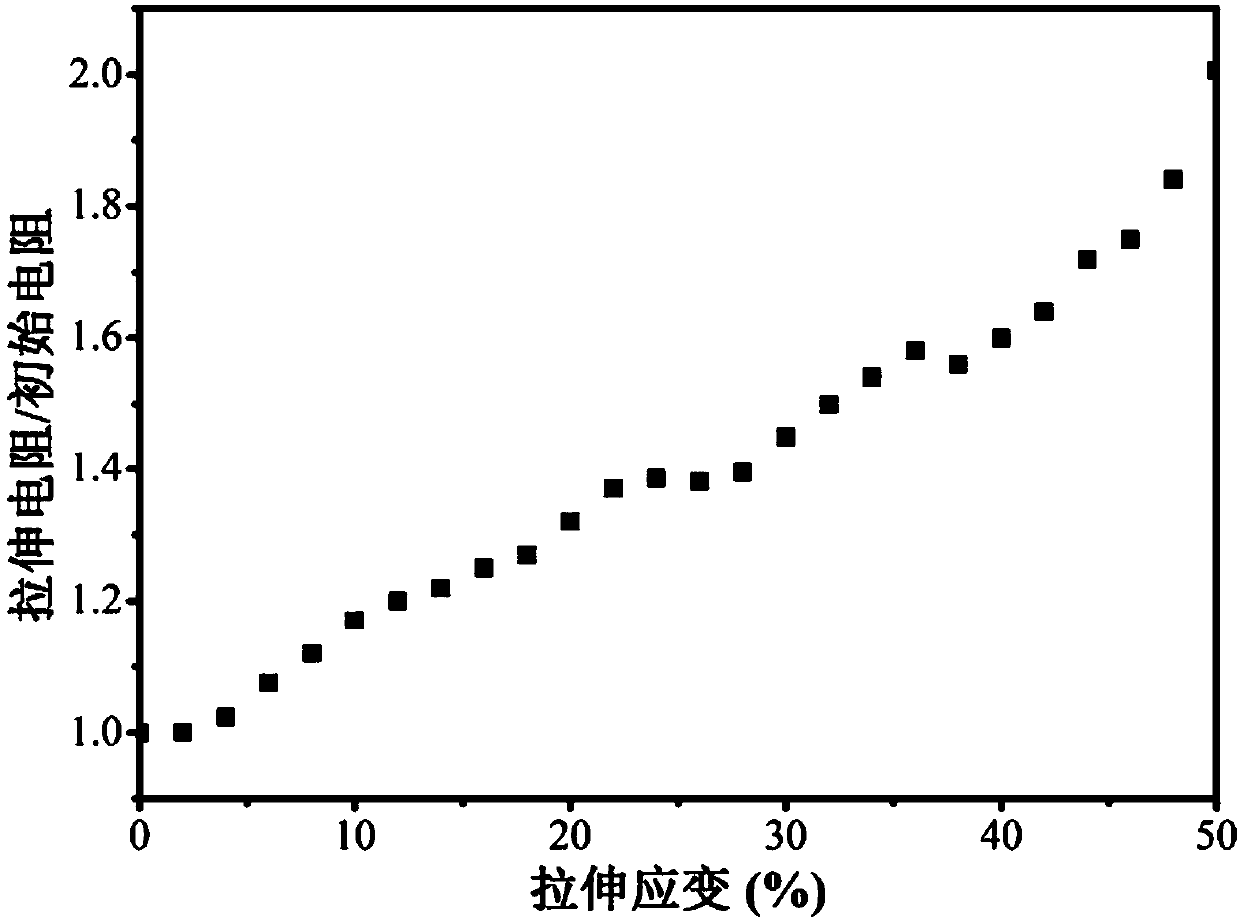

A super-hydrophobic coating, flexible conductive technology, applied in conductive coatings, coatings, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of intolerant stretching and bending of conductive coatings, and easy damage to conductivity , No problems such as hydrophobicity, to achieve the effect of excellent hydrophobicity and electrical conductivity, excellent stretchability, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

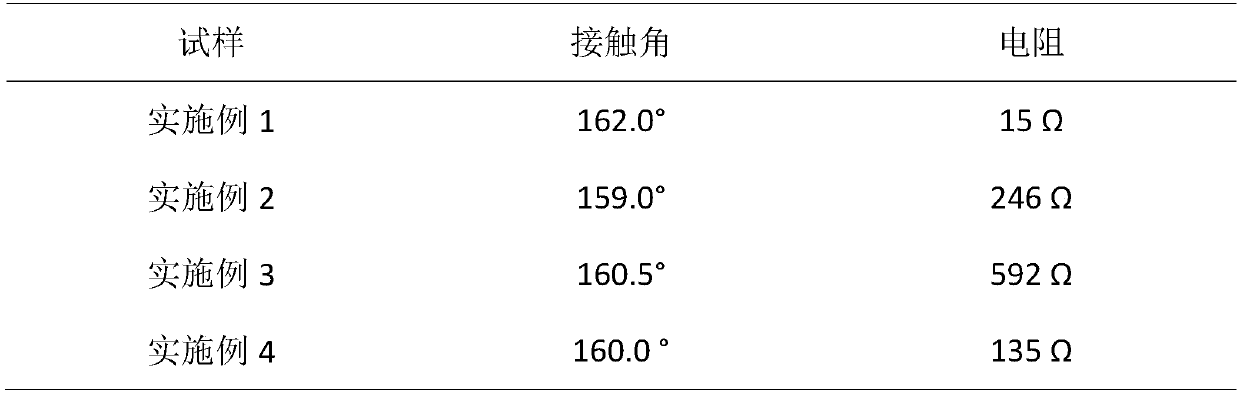

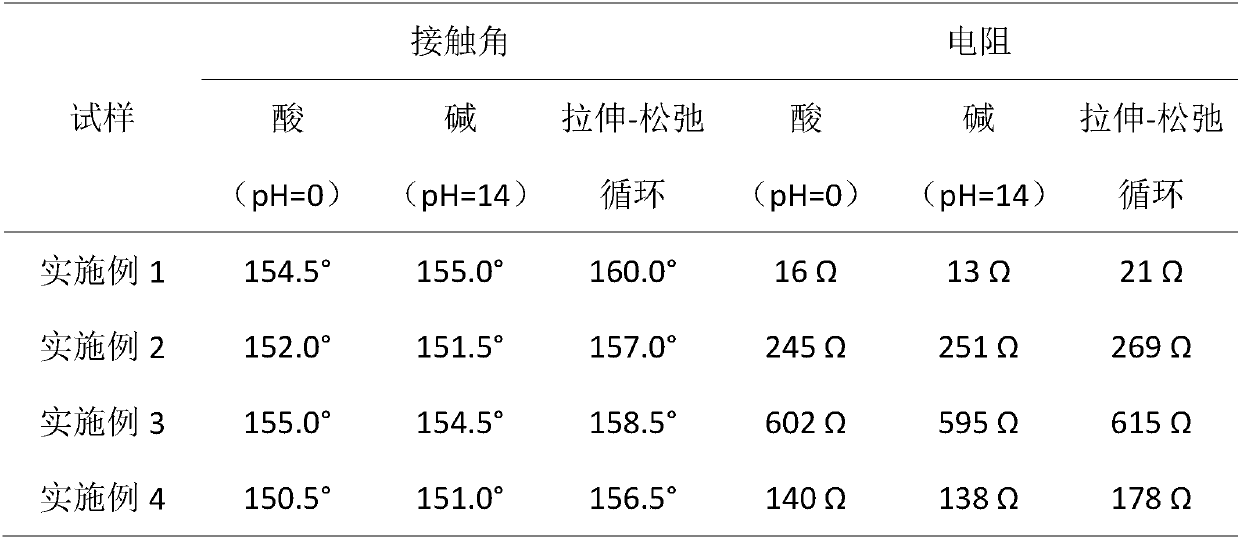

Embodiment 1

[0027] 2g of silver particles with a size of 100‐200nm were dispersed in 100g of ethanol solution of 1wt% cetyl mercaptan, ultrasonically dispersed for 15min and stirred at room temperature for 8h, then centrifuged at 8000rpm for 20min, and the product was used After washing with ethanol, vacuum-dry at 40°C for 8 hours to obtain hydrophobic silver particles. Add 0.35 g of hydrogenated styrene-butadiene-styrene block copolymer to 17.5 g of toluene, stir at 40°C for 5 h, then add 1.05 g of hydrophobic silver particles, and ultrasonically disperse for 1 h to obtain a mixed dispersion. Secondly, pre-stretch the natural rubber base to 3 times the original length with an external force, and use a spray gun (working pressure is 0.6MPa, the distance between the spray gun and the rubber base is 15cm, the moving speed is 1cm / s, and the spray gun reciprocates and sprays for 2 cycles) to spray the mixed dispersion Spray on rubber substrates. Finally, the coating was dried at 30°C for 15 ...

Embodiment 2

[0034] 3g of silver particles with a size of 250-300nm were dispersed in 100g of ethanol solution of 0.5wt% tetramercaptan, ultrasonically dispersed for 5min and stirred at room temperature for 3h, then centrifuged at 6000rpm for 30min, and the product After washing with ethanol, vacuum-dry at 30°C for 12 hours to obtain hydrophobic silver particles. Add 0.4g of styrene-isoprene-styrene block copolymer to 16g of xylene, stir at 30°C for 12h, then add 1.2g of hydrophobic silver particles, and ultrasonically disperse for 1h to obtain a mixed dispersion. Secondly, pre-stretch the natural rubber base to 2.5 times the original length with an external force, and use a spray gun (working pressure is 0.7MPa, the spray gun is 20cm away from the rubber base, the moving speed is 2cm / s, and the spray gun reciprocates and sprays for 2 cycles) to mix the dispersion Spray on rubber substrates. Finally, the coating was dried at 30°C for 30 min to fully volatilize the solvent, and then the ex...

Embodiment 3

[0039] Disperse 2g of silver particles with a size of 200-300nm in 100g of ethanol solution of dodecanethiol and cetyl mercaptan (the mass ratio of dodecanethiol and cetyl mercaptan is 1) with a mass concentration of 100g, ultrasonically disperse for 20min and Continue to stir at room temperature for 10 h, then centrifuge at 8000 rpm for 15 min, wash the product with ethanol and then vacuum dry at 40° C. for 8 h to obtain hydrophobic silver particles. Add 0.3 g of hydrogenated styrene-isoprene-styrene block copolymer to 15 g of toluene, stir at 50 °C for 5 h, then add 1.2 g of hydrophobic silver particles, and ultrasonically disperse for 2 h to obtain a mixed dispersion. Secondly, use external force to pre-stretch the silicone rubber base to 3 times the original length, use a spray gun (working pressure is 0.5MPa, the distance between the spray gun and the rubber base is 15cm, the moving speed is 1.5cm / s, and the spray gun reciprocates and sprays for 1 cycle) to mix and dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com