Method for preparing peanut polypeptide solution by utilizing peanut intrinsic protease to hydrolyze peanut protein

A technology of protease hydrolysis and peanut polypeptide is applied in the processing field of vegetable protein and oil, which can solve the problems of low economic value and achieve the effect of low processing cost, healthy nutrition and good function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

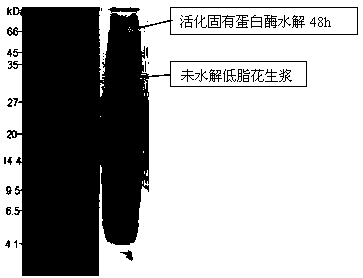

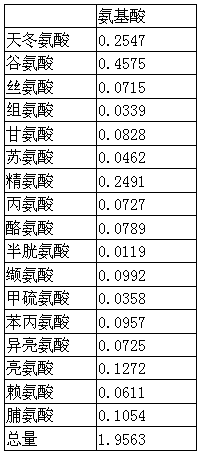

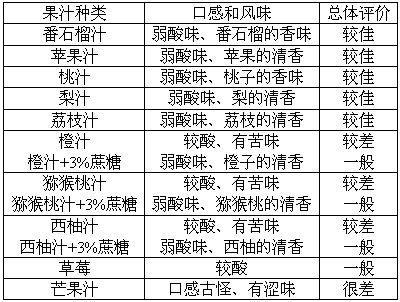

[0022] Soak the peanuts for 12 hours, remove the red coat, remove mildew and deterioration of peanut kernels, rinse, add water of 6 times the mass of peanut kernels, refining for 2 minutes, filter to obtain peanut pulp and peanut residue; peanut pulp is centrifuged at 9600 rpm for 3 minutes, Obtain low-fat peanut pulp and peanut oil body enrichment; adjust the pH of low-fat peanut pulp to 2 with hydrochloric acid, activate at 50℃ for 1h, adjust pH to 2.5 with sodium bicarbonate, and keep it at 60℃ for 48h, Obtain low-fat peanut polypeptide liquid; add apple juice according to the ratio of apple juice / low-fat peanut polypeptide liquid=1 / 9, mix, homogenize, sterilize (90℃, 10min), and package to obtain apple juice peanut polypeptide liquid beverage. The centrifuge is a three-phase centrifuge or a disc centrifuge.

Embodiment 2

[0024] Soak the peanuts for 15 hours, remove the red coat, remove moldy and deteriorated peanut kernels, rinse, add water of 4 times the quality of peanut kernels, refining for 2 minutes, filter to obtain peanut pulp I and peanut residue I; add water to peanut residue I , Peanut pulp I: water mass ratio is 1:3, refining for 1 min to obtain peanut pulp II and peanut pulp II; peanut pulp I and peanut pulp II are mixed to obtain peanut pulp III; peanut pulp III is centrifuged at 7000 rpm for 3 minutes, Obtain low-fat peanut syrup and peanut oil body enrichment; adjust the pH of low-fat peanut syrup to 1.8 with phosphoric acid and activate it at 40℃ for 2h; adjust the pH to 2.3 with sodium carbonate and keep it at 55℃ for 55h to obtain low-fat Peanut polypeptide liquid: add peach juice at the ratio of peach juice / low-fat peanut polypeptide liquid=1 / 9, mix, homogenize, sterilize (95℃, 5min), and pack to obtain peach juice peanut polypeptide liquid beverage. The centrifuge is a three...

Embodiment 3

[0026] Soak the peanuts for 15h, remove the red coat, remove moldy and deteriorated peanut kernels, rinse, add water of 6 times the mass of peanut kernels, refining for 2 minutes, filter to obtain peanut pulp I and peanut residue I; add water to peanut residue I , Peanut pulp I: water mass ratio 1:3, refining for 1.5 minutes to obtain peanut pulp II and peanut pulp II; peanut pulp I and peanut pulp II are mixed to obtain peanut pulp III; peanut pulp III is centrifuged at 5000 rpm for 5 minutes To obtain low-fat peanut pulp and peanut oil body enrichment; adjust the pH of low-fat peanut pulp to 3 with hydrochloric acid, and activate it at 60℃ for 1.5h; without adjusting pH, keep it at 55℃ for 60h to obtain low-fat peanut polypeptide Liquid; add guava juice at the ratio of guava juice / low-fat peanut polypeptide liquid=1 / 9, mix, homogenize, sterilize (80℃, 15min), and package to obtain guava juice peanut polypeptide liquid beverage. The centrifuge is a three-phase centrifuge or a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com