Hypergravity method metal organic ligand doped amino acid composite material and preparation method thereof

A metal-organic, high-gravity technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve problems affecting the application of MOFs, weak selective adsorption, long synthesis time, etc., to achieve Improved selective adsorption capacity, fast synthesis speed, and short time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

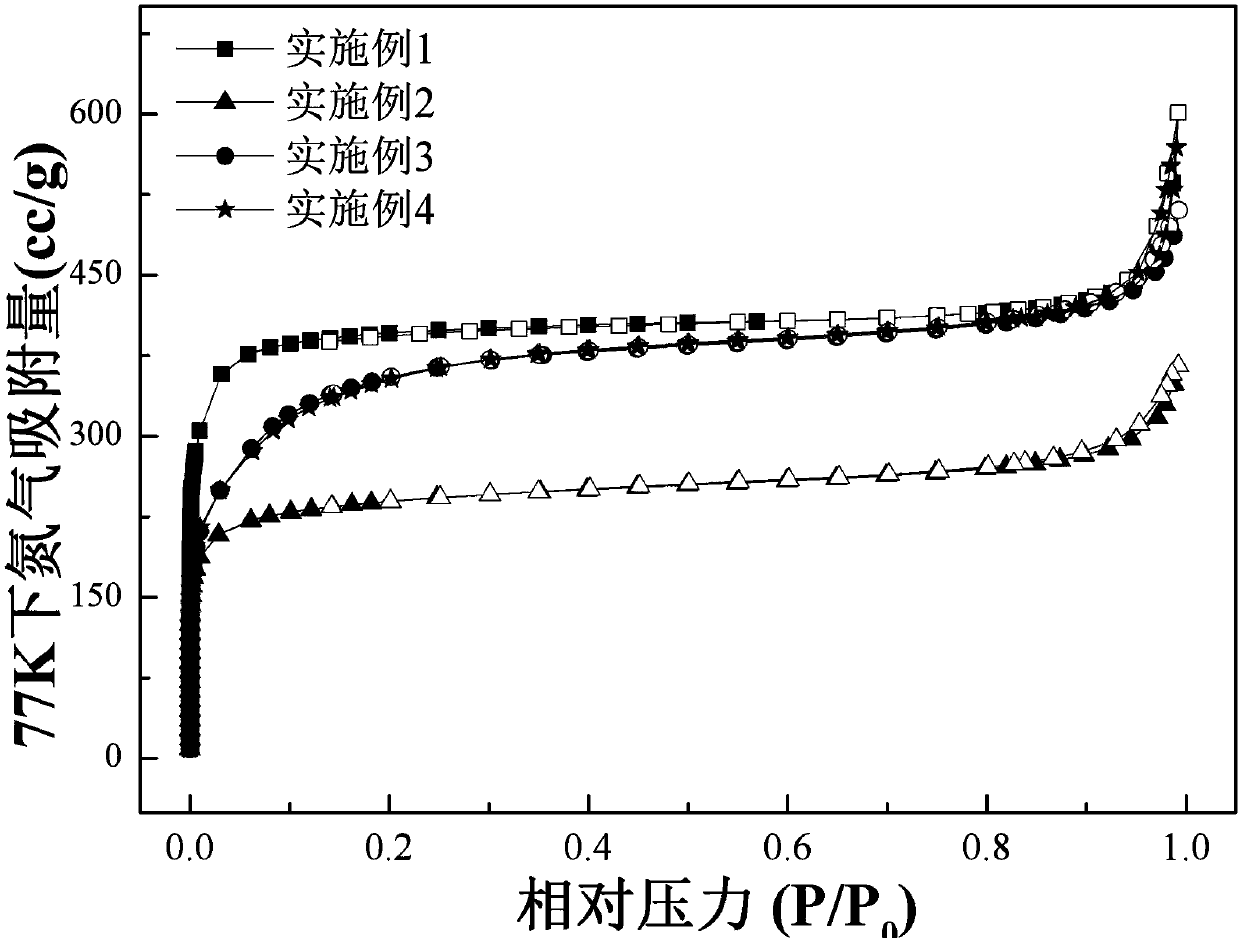

Embodiment 1

[0031] A method for preparing a metal-organic ligand-doped amino acid composite material by the hypergravity method, comprising the following steps,

[0032] (1) Preparation of zirconium chloride solution: put 25mL N,N-dimethylformamide (DMF) solvent in a 50mL beaker, weigh 1.0mmol zirconium chloride (ZrCl 4 ) was slowly added into the beaker, and the beaker was placed on the stirring device to stir magnetically at a speed of 400rmp / min to fully dissolve the zirconium chloride, which was recorded as solution A;

[0033] (2) Preparation of terephthalic acid solution: take 2.0mmol terephthalic acid (H 2 BDC) was dissolved in N,N- dimethylformamide (DMF) solvent to make it fully dissolved, and then 1.439g of proline was added therein; denoted as solution B;

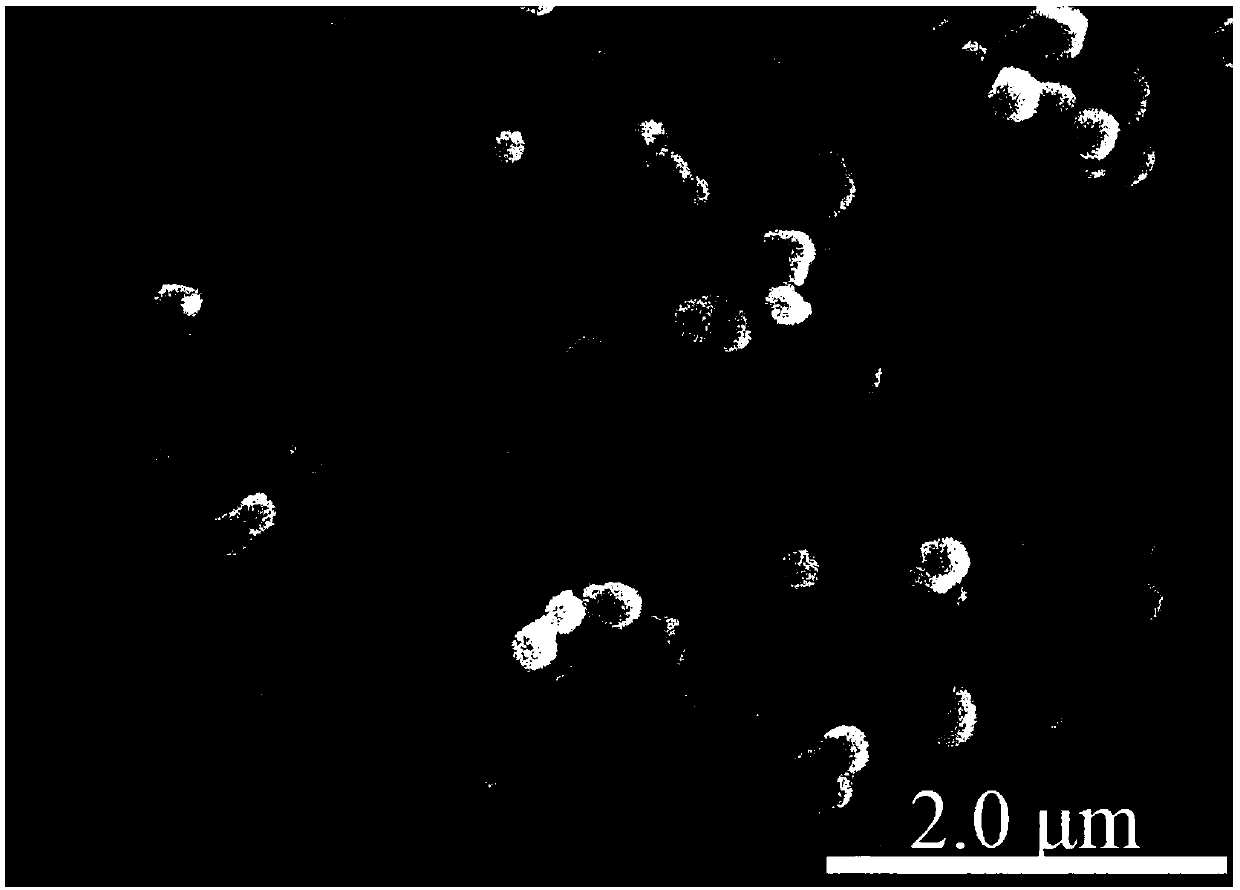

[0034] (3) Preparation of composite material: solution B was added dropwise into solution A while being magnetically stirred. Then add 1.6mL glacial acetic acid to the above mixed solution, transfer the whole mixed solutio...

Embodiment 2

[0036] A method for preparing a metal-organic ligand-doped amino acid composite material by the hypergravity method, comprising the following steps,

[0037] (1) Preparation of zirconium chloride solution: put 15mL N,N-dimethylformamide (DMF) solvent in a 50mL beaker, weigh 1.0mmol zirconium chloride (ZrCl 4 ) is slowly added in the beaker, and the beaker is placed on the stirring device with magnetic stirring at a speed of 500rmp / min to fully dissolve the zirconium chloride, which is recorded as solution A;

[0038] (2) Preparation of terephthalic acid solution: take 1.0mmol terephthalic acid (H 2 BDC) was dissolved in N, N- dimethylformamide (DMF) solvent to make it fully dissolved, and 1.734g of phenylalanine was added therein; denoted as solution B;

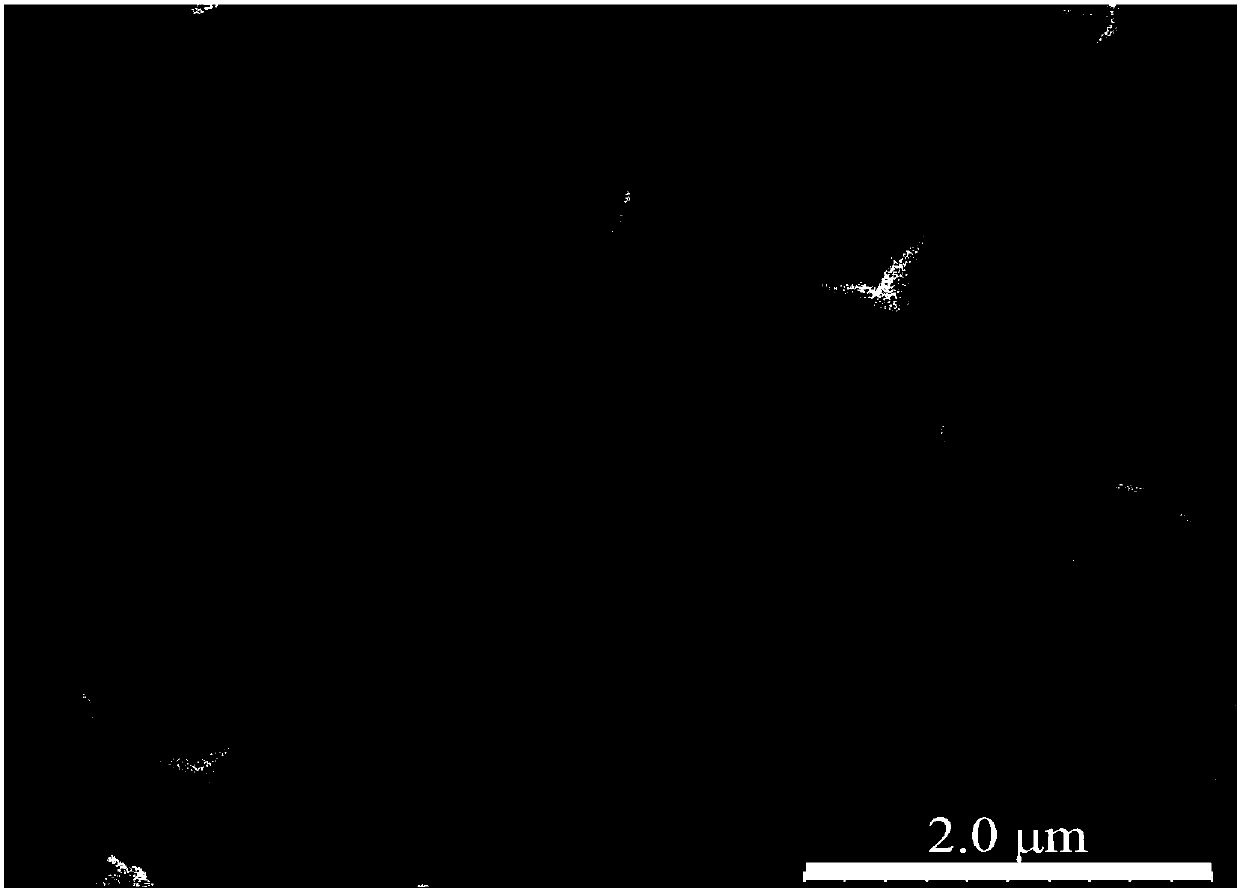

[0039] (3) Preparation of composite material: solution B was added dropwise into solution A while being magnetically stirred. Then add 2.0mL glacial acetic acid to the above mixed solution, transfer the whole mixed solution...

Embodiment 3

[0041] A method for preparing a metal-organic ligand-doped amino acid composite material by the hypergravity method, comprising the following steps,

[0042] (1) Preparation of zirconium chloride solution: put 35mL N,N-dimethylformamide (DMF) solvent in a 50mL beaker, weigh 1.0mmol zirconium chloride (ZrCl 4 ) is slowly added in the beaker, and the beaker is placed on the stirring device to make zirconium chloride fully dissolve with magnetic stirring at a speed of 300rmp / min, which is recorded as solution A;

[0043] (2) Preparation of terephthalic acid solution: take 3.0mmol terephthalic acid (H 2 BDC) was dissolved in N,N- dimethylformamide (DMF) solvent to make it fully dissolved, and then 2.144g of tryptophan was added therein; denoted as solution B;

[0044] (3) Preparation of composite material: solution B was added dropwise into solution A while being magnetically stirred. Then add 1.4mL glacial acetic acid to the above mixed solution, transfer the whole mixed solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com