Additive for accelerating pig manure composting maturity and preparation method and application thereof

An additive and composting technology, applied in the preparation, application, organic fertilizer and other directions of organic fertilizers, can solve the problems affecting the degree of decomposing, restrictions, etc., and achieve the effect of accelerating the decomposing process, stabilizing the properties, and accelerating the decomposing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing an additive for quickening pig manure composting, comprising the following steps:

[0025] 1) Anaerobically heating the pulverized wood powder at 90-120°C for 1-1.5 hours, and then carbonizing at 500-600°C for 2-3 hours to obtain a wood charcoal material;

[0026] 2) mixing the wood charcoal material obtained in the step 1) with hydrochloric acid solution, washing the mixture to make the pH value to neutral, drying, and grinding to obtain carbonized wood powder;

[0027] 3) Mix and impregnate the carbonized wood powder obtained in step 2) with 1 to 1.5mol / L thiourea solution to obtain a suspension; the volume ratio of the carbonized wood powder to the thiourea solution is 1mg: 4~8ml;

[0028] 4) The suspension obtained in step 3) is solidified at 100-120° C. for 1-2 hours, and then washed with water to make the pH value to neutral, which is an additive for accelerating the composting of pig manure.

[0029] In the present ...

Embodiment 1

[0048] Rinse the collected sycamore wood with tap water, dry at 90°C after rinsing with distilled water, pulverize, pass through a 10-mesh sieve, and store for later use.

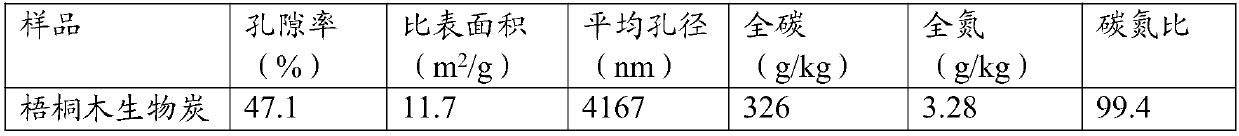

[0049] Put the crushed sycamore wood above in a high-temperature electric furnace, heat it anaerobically, first carbonize at 100°C for 1.5h, then raise the temperature to 550°C for 2h, cool it for 12h, remove the ash with 1mol / L dilute hydrochloric acid, and use Rinse with distilled water until neutral. The deashed biochar was dried in a drying oven to constant weight, ground into powder and passed through a 20-mesh sieve, and stored for later use.

[0050] Take the biomass carbonized material, add 1 mol / L thiourea solution according to the addition amount of solid-to-liquid ratio 1:4, soak for 3 hours, and place it in an electric furnace for curing at 120°C for 1 hour. After the sample is cooled, it is washed repeatedly with distilled water until the filtrate is neutral, and the new pig manure composting ...

Embodiment 2

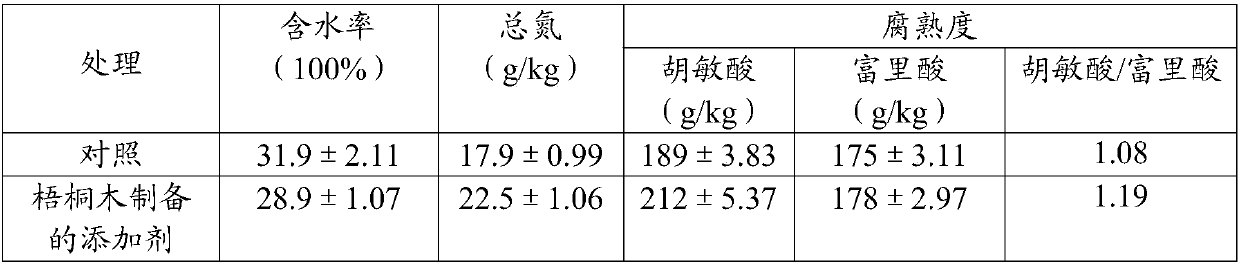

[0056] Pig manure is mixed with carbon source material and the novel compost additive prepared above (the addition amount is 2.5% of the total mass dry weight of fermentation raw materials), and then 0.75% of EM fermentation bacteria liquid is added, and the moisture content of the material is adjusted to 70%. Thoroughly mix and stir, add 0.25% EM fermentation broth, and adjust the water content of the material to 60%, to obtain the fermented material. Among them, the carbon source material is corncobs with a particle size not greater than 2cm. After the fermented material is mixed evenly, conventional composting can be carried out according to the pig manure composting technical operation regulations (DB36 / T 836-2015).

[0057] The moisture content was determined by the drying method. The total nitrogen content was determined by an elemental analyzer.

[0058] Pass the air-dried compost sample through a 60m sieve, add 0.1mol / L sodium hydroxide mixture at a ratio of 1:20 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com