Treatment method of tetracycline crystal mother liquor

A technology of crystallization mother liquor and treatment method, which is applied in the field of treatment of tetracycline crystallization mother liquor, can solve the problems of difficult biochemical treatment of tetracycline crystallization mother liquor, high treatment cost, low treatment efficiency, etc., and achieves the advantages of easy biochemical treatment, volume reduction and increased benefit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Take 8L of tetracycline crystallization mother liquor, add 80g of solid calcium hydroxide, stir for 10min, add 160ml of polyaluminum chloride solution with a concentration of 40%, stir for 12min, add 80ml of anionic polyacrylamide solution with a concentration of 0.2%, stir slowly for 5min, and filter through a double layer Cloth (inner 621, outer 758) plate and frame filtration to obtain 7L filtrate, take 10L of tetracycline fermentation broth, measure its potency unit as 30000u / ml, add 5L of filtrate to dilute, carry out acidification and release, and the titer of acidification solution is 19980u / ml, Ceramic membrane filtration, crystallization.

Embodiment 2

[0016] Take 10L of tetracycline crystallization mother liquor, add 100g of solid calcium hydroxide, stir for 12min, add 200ml of polyaluminium chloride solution with a concentration of 40%, stir for 13min, add 100ml of anionic polyacrylamide solution with a concentration of 0.2%, stir slowly for 5min, and filter through a double layer Cloth (inner 621, outer 758) plate and frame filtration to obtain 9L filtrate, take 10L of tetracycline fermentation broth, measure its titer unit as 30000u / ml, add 5.8L of filtrate to dilute, carry out acidification and release, and the titer of acidification solution is 19334u / ml , ceramic membrane filtration, separation liquid crystallization.

Embodiment 3

[0018] Take 15L of tetracycline crystallization mother liquor, add 150g of solid calcium hydroxide, stir for 15min, add 300ml of polyaluminum chloride solution with a concentration of 40%, stir for 15min, add 150ml of anionic polyacrylamide solution with a concentration of 0.2%, stir slowly for 5min, and filter through a double layer Cloth (inner 621, outer 758) plate and frame filter to obtain 13.5L filtrate, take 10L of tetracycline fermentation broth, measure its potency unit as 30000u / ml, add 6.7L of filtrate to dilute, carry out acidification and release, and the titer of acidification solution is 18021u / ml ml, filtered by ceramic membrane, crystallized.

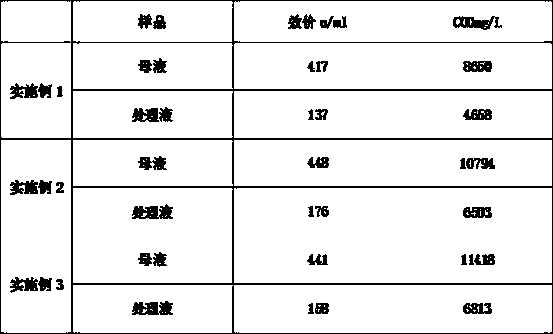

[0019] Below is the detection data of above-mentioned embodiment 1,2 and 3:

[0020]

[0021] Table 1: Comparison data of potency and COD before and after treatment with tetracycline mother liquor

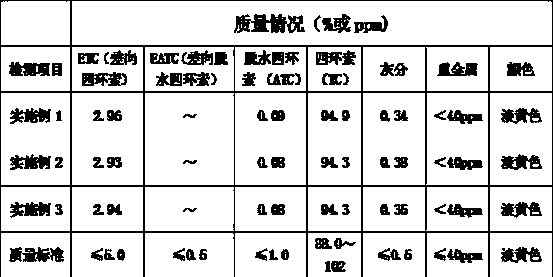

[0022] Table 2: Quality of Crystalline Products

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com