A kind of method preparing 3-aminopropionitrile under supercritical condition

An aminopropionitrile and supercritical technology, which is applied in the preparation of carboxylic acid nitriles, chemical instruments and methods, and the preparation of organic compounds, can solve problems such as complex processes, limited development, and increased costs, so as to avoid separation difficulties and shorten the reaction time. time, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

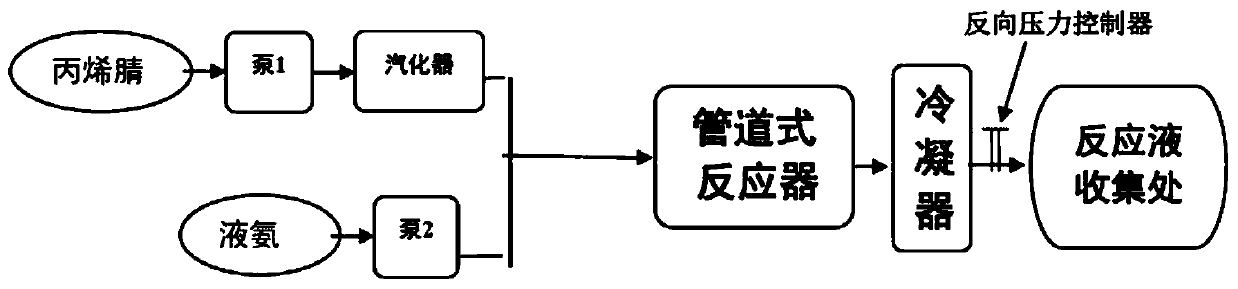

[0040] by such as figure 1 As shown in the reaction flow chart, turn on metering pump 1, pump in acrylonitrile at a constant rate of 2ml / min, set the temperature of the vaporizer at 90°C, turn on liquid ammonia metering pump 2, and pump in liquid ammonia at a constant rate of 9ml / min , The temperature of the supercritical pipeline reactor is set at 160°C, the high-precision reverse pressure controller after the condenser is adjusted, the pressure is controlled at 15±1MPa, and the reaction residence time is 20min. After the reaction was completed, the reaction solution was collected, the organic layer was separated, and analyzed by gas chromatography. It was calculated that the conversion rate of acrylonitrile was 100%, and the selectivity of 3-aminopropionitrile was 90.2%.

Embodiment 2-22

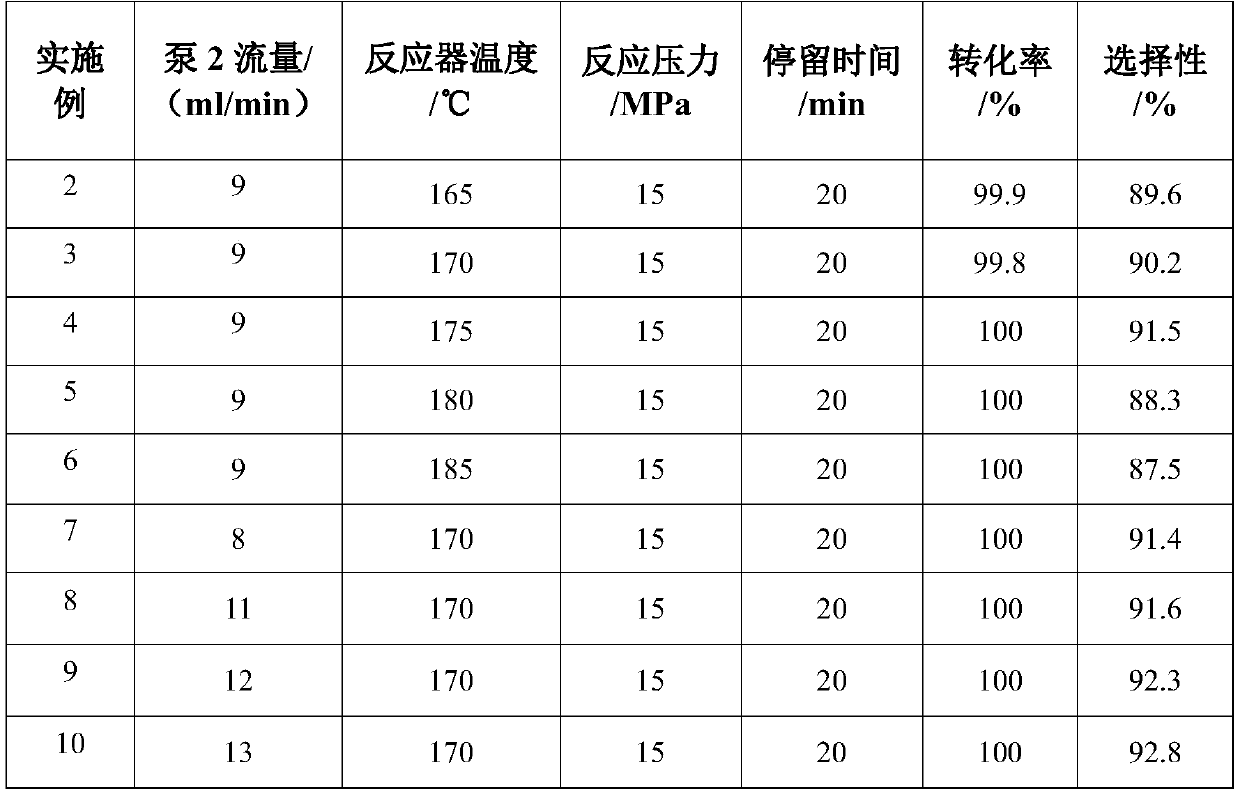

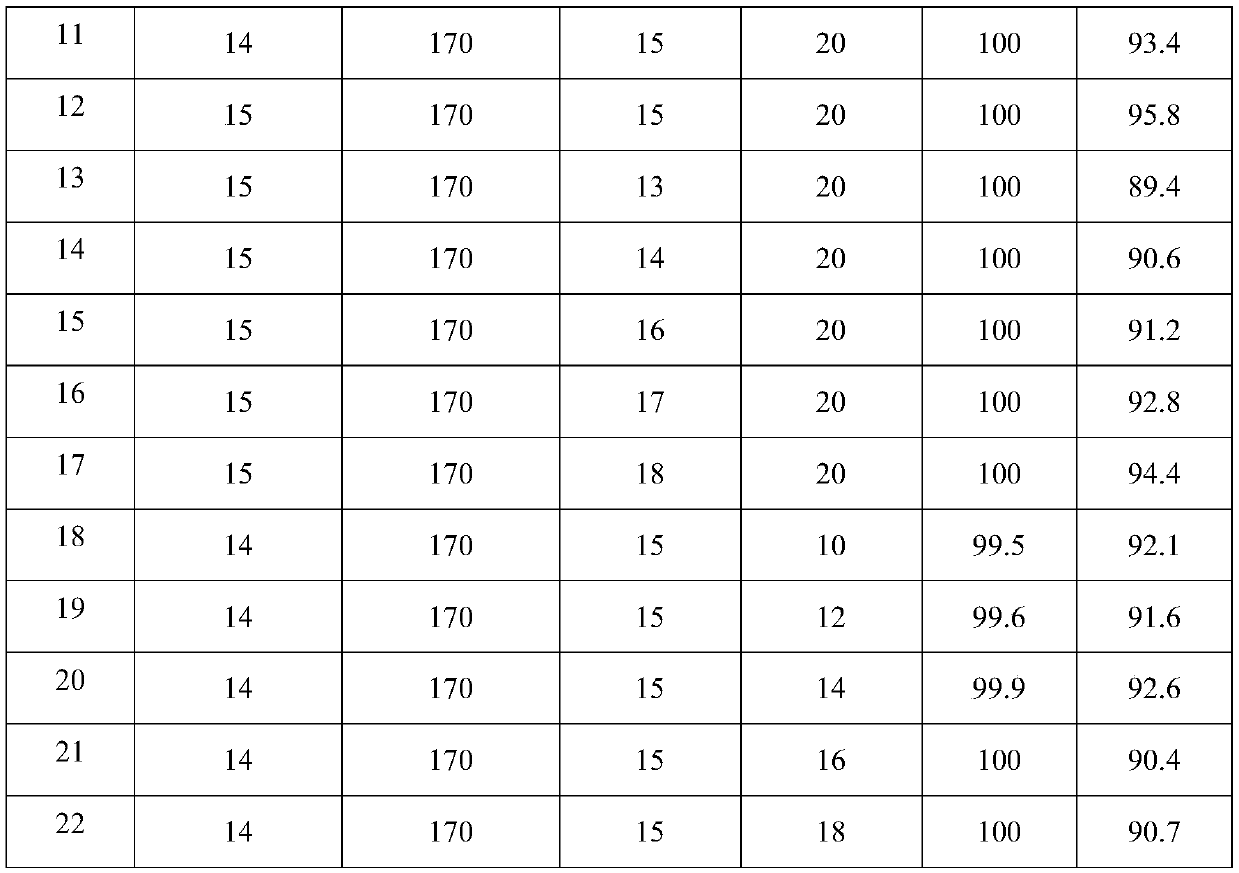

[0042] According to the operation method of embodiment 1, change reaction conditions: liquid ammonia flow rate, reactor temperature, reaction pressure, residence time, obtain reaction liquid, its reaction conditions and reaction result are as shown in table 1.

[0043] The reaction condition and reaction result of table 1 embodiment 2~22

[0044]

[0045]

[0046] As can be seen from the results in Table 2, under the supercritical conditions of the present invention, without adding additional catalyst and solvent, the reaction can also obtain better conversion and selectivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com