Vegetable fiber modified material for 3D printer bases

A 3D printer and plant fiber technology, applied in the direction of additive processing, etc., can solve the problems affecting the processing yield of 3D printing workpieces and product quality stability, the influence of 3D printing equipment processing operations on the forming accuracy, and the poor shock resistance and shock absorption capacity of metal structures and other issues, to achieve the effect of improving reliability and stability, good heat insulation and heat preservation performance, and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

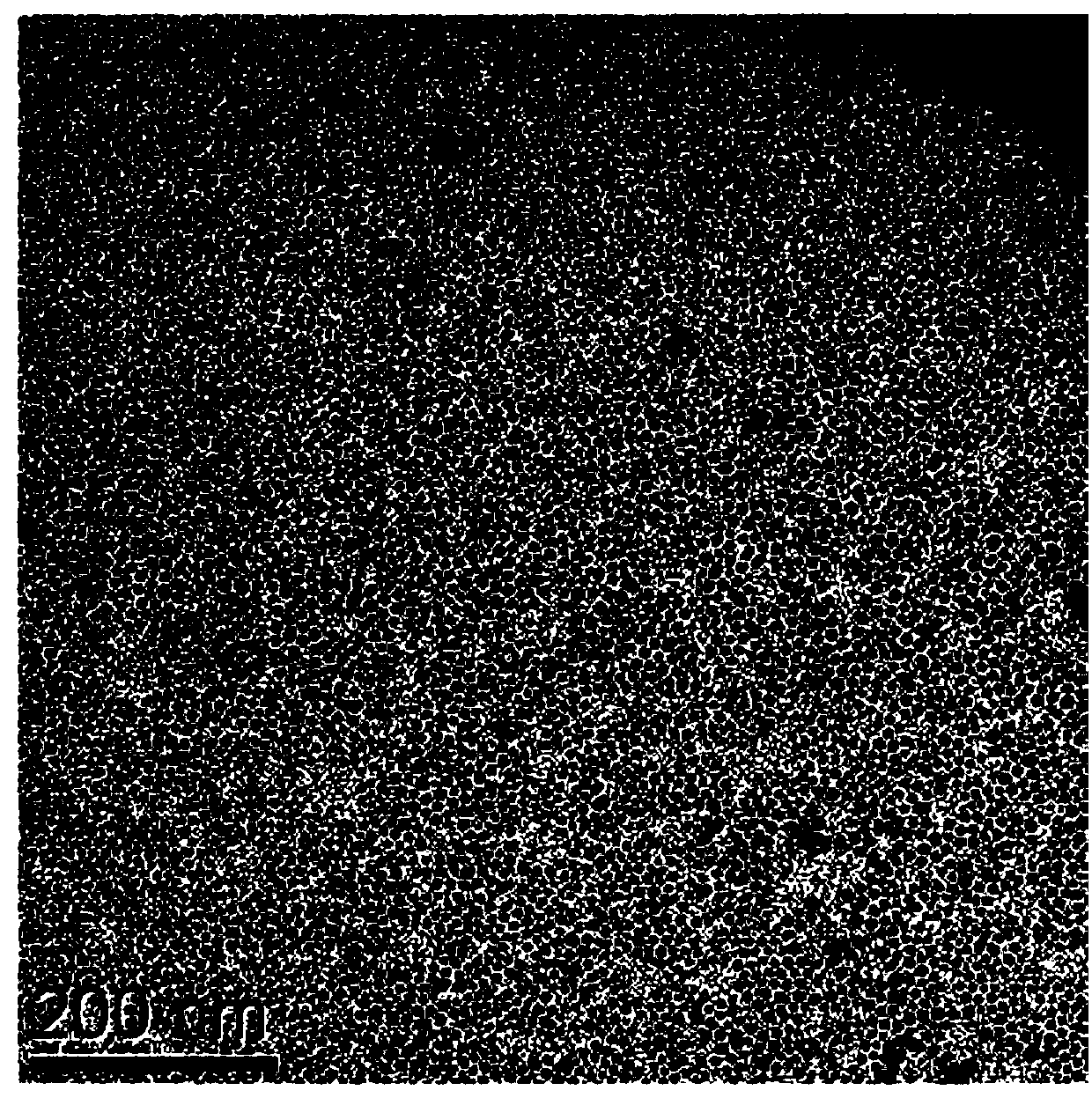

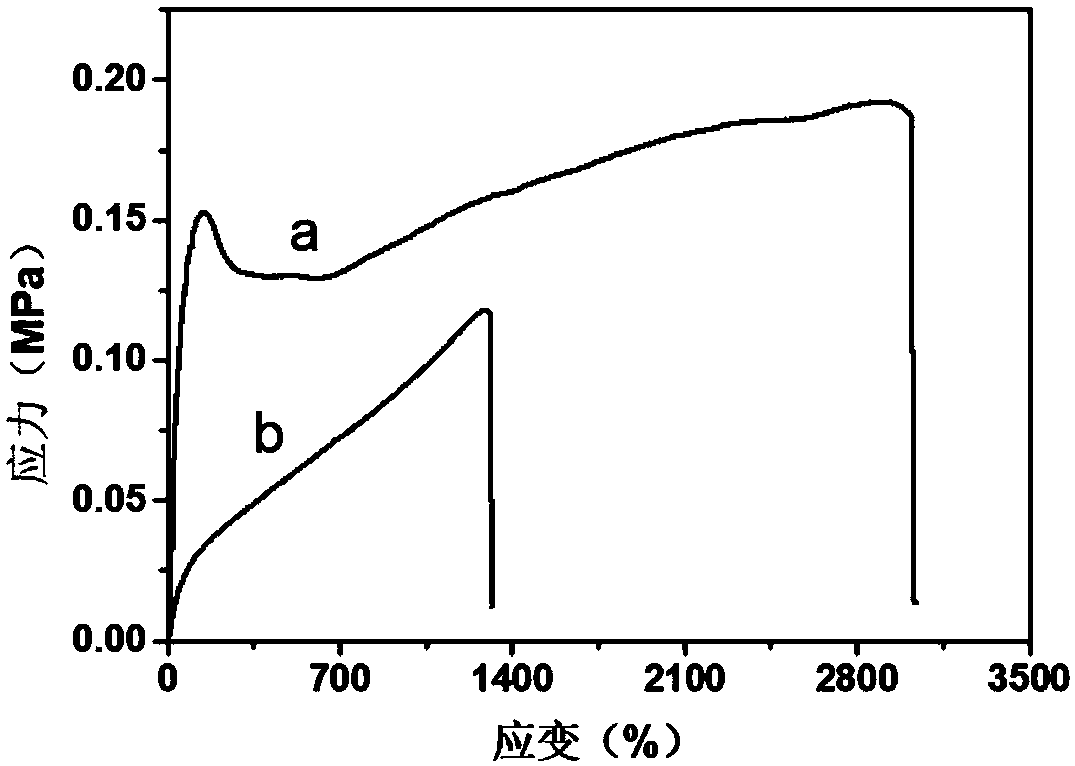

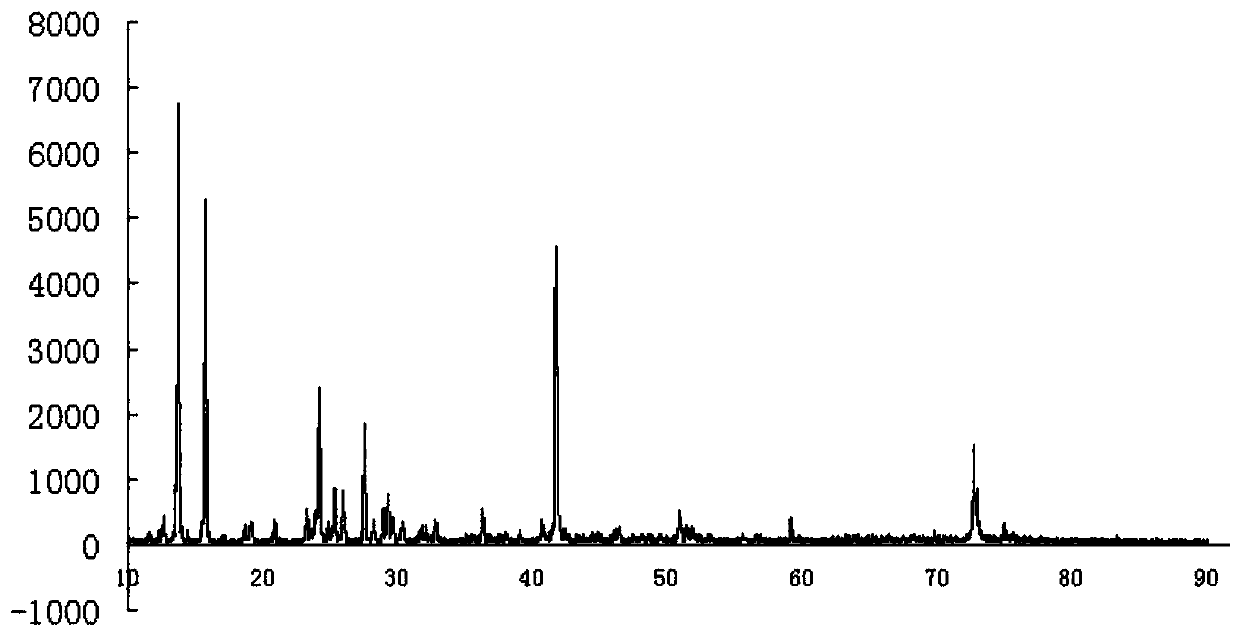

[0020] Such as figure 1 -3, a plant fiber modified material for a 3D printer base is made of the following materials in parts by mass: 1% hydroxyapatite, 1.5% calcium carbonate, 7.5% ceramic particle powder, 4.5% manganese alloy powder, Plant fiber powder 15%, thermoplastic elastomer 3.8%, polyamine curing agent 2.5%, n-butanol 1.1%, 0.2% antioxidant 1010, even light yellow 0.5%, 1.1% silane coupling agent KH-590 , 2% of diisocyanate bonded crystalline chain extender, 1.5% of graphene fiber, 1.6% of nylon fiber, and the balance is polylactic acid.

[0021] In this embodiment, the hydroxyapatite is 400-mesh powdered basic calcium phosphate, and the calcium carbonate, ceramic particle powder, alloy powder and plant fiber powder are all 500-mesh powder structures.

Embodiment 2

[0023] Such as figure 1 Shown in -3, a plant fiber modified material for a 3D printer base is composed of the following substances in parts by mass: calcium carbonate 2.8%, ceramic particle powder 3.5%, copper alloy powder 6.5%, plant fiber powder 25%, thermosetting Elastomer 2.8%, acid anhydride curing agent 2.5%, polyethylene glycol 0.5%, 0.2% antioxidant 168, lead cadmium yellow 0.4%, diisocyanate combined crystalline chain extender 1.1%, nylon fiber 4.6%, the balance It is an acrylonitrile-butadiene-styrene terpolymer.

[0024] In this embodiment, the calcium carbonate, ceramic particle powder, alloy powder and plant fiber powder all have a powder structure of 400 mesh.

Embodiment 3

[0026] Such as figure 1 As shown in —3, a plant fiber modified material for a 3D printer base is composed of the following substances in parts by mass: 2% hydroxyapatite, 0.5% calcium carbonate, 6.5% ceramic particle powder, and 3.5% aluminum-magnesium alloy powder , plant fiber powder 10%, toughening agent 2.5%, polyamines 4.5%, silane coupling agent 1.1%, 0.8% antioxidant 626, iron blue 0.4%, graphene fiber 1.5%, nylon fiber 1.6%, The balance is polycaprolactone.

[0027] In this embodiment, the hydroxyapatite is 300-mesh powdered basic calcium phosphate, and the calcium carbonate, ceramic particle powder, alloy powder and plant fiber powder are all 500-mesh powder structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com