A kind of modified rosin resin and its preparation method and application

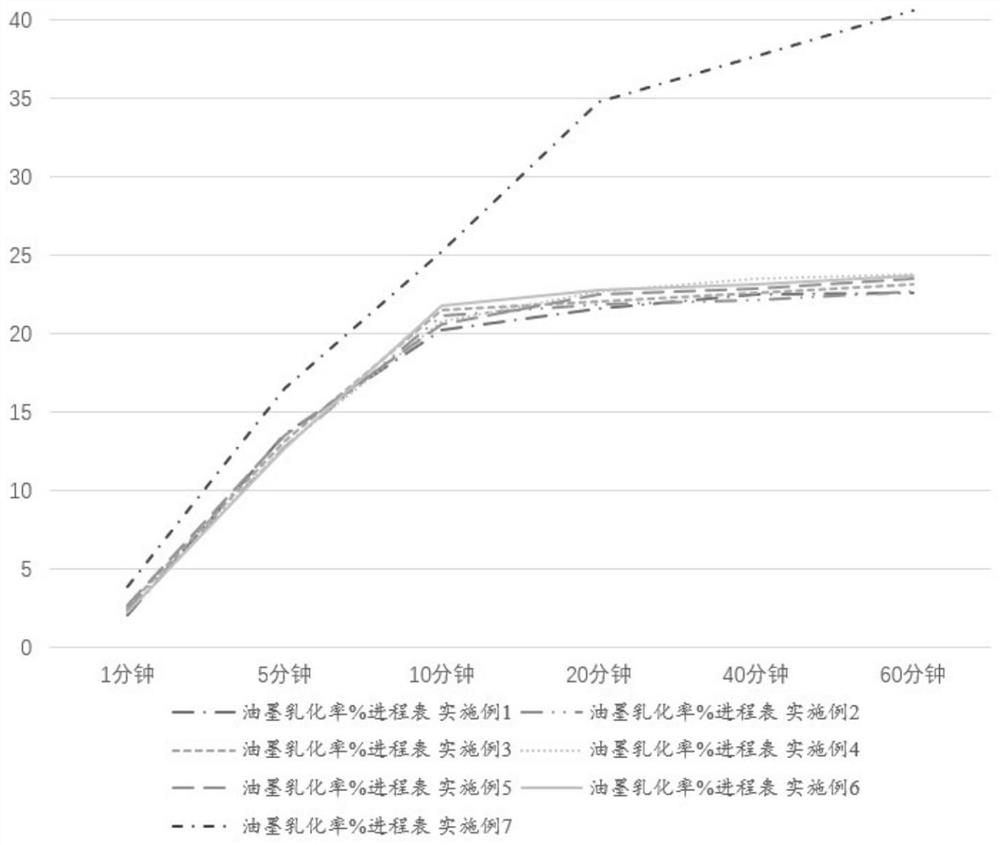

A technology for modifying rosin and resin, which is applied in application, rosin coating, rosin adhesive, etc. It can solve problems such as changing ink performance, ink emulsification, and destroying ink structure, so as to improve water resistance, avoid solvent residual defects, and improve performance. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The embodiment of the present invention provides a kind of preparation method of modified rosin resin, comprises the following steps:

[0060] (1) Add 30.2g (0.1mol) of gum rosin and 34g (0.1mol) of epoxy resin DER331 into a 500mL three-neck bottle with mechanical stirring, raise the temperature to 140°C, pump negative pressure to promote the melting of the reactants, and then lower the temperature To 100°C, add 0.76g of triphenylphosphine and 12.2g (0.1mol) of benzoic acid, and stir at 100°C for 3 hours;

[0061] (2) Add 24.80 g (0.2 mol) of p-hydroxyanisole and 23.2 g (0.2 mol) of maleic acid, and react at 150°C for 3 hours to obtain modified rosin resin 1.

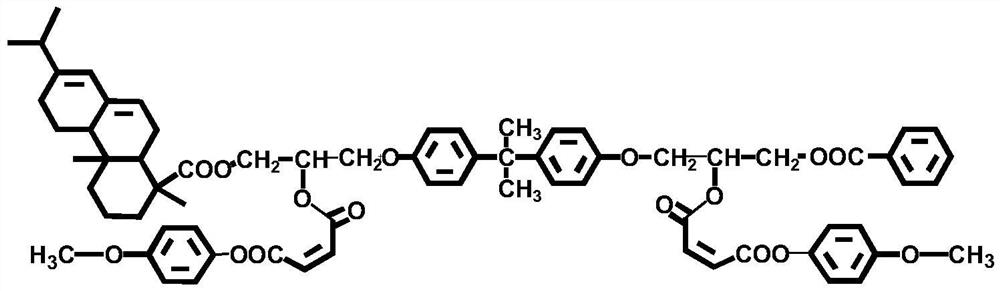

[0062] Test result shows, the structural formula of modified rosin resin one is as follows:

[0063]

Embodiment 2

[0065] The embodiment of the present invention provides a kind of preparation method of modified rosin resin, comprises the following steps:

[0066] (1) Add 45.3g (0.15mol) of gum rosin and 34g (0.1mol) of epoxy resin DER331 into a 500mL three-necked bottle with mechanical stirring, raise the temperature to 140°C, pump negative pressure to promote the melting of the reactants, and then lower the temperature To 90°C, add 0.76g of triphenylphosphine and 8.3g (0.05mol) of isophthalic acid, and stir at 90°C for 4 hours;

[0067] (2) Add 27g (0.15mol) of butyl hydroxyanisole and 17.4g (0.15mol) of maleic acid, and react at 140°C for 4 hours to obtain modified rosin resin II.

Embodiment 3

[0069] The embodiment of the present invention provides a kind of preparation method of modified rosin resin, comprises the following steps:

[0070] (1) In a 500mL three-necked bottle with mechanical stirring, add 60.5g (0.1mol) of polymerized rosin and 17.4g (0.1mol) of ethylene glycol diglycidyl ether, raise the temperature to 140°C, and pump negative pressure to promote the reaction of the reactants. Melt, then lower the temperature to 110°C, add 0.76g of triphenylphosphine and 8.3g (0.05mol) of phthalic acid, and stir at 110°C for 2 hours;

[0071] (2) Add 11.6g (0.1mol) 4-hydroxybutyl vinyl ether and 11.6g (0.1mol) maleic acid, and react at 160°C for 2 hours to obtain modified rosin resin III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com