Low-sulfur biofuel

A biofuel and raw material technology, applied in the field of fuel, can solve problems such as air pollution, low calorific value, and insufficient stability, and achieve the effects of simple formula, high octane number and calorific value, and remarkable exhaust emission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

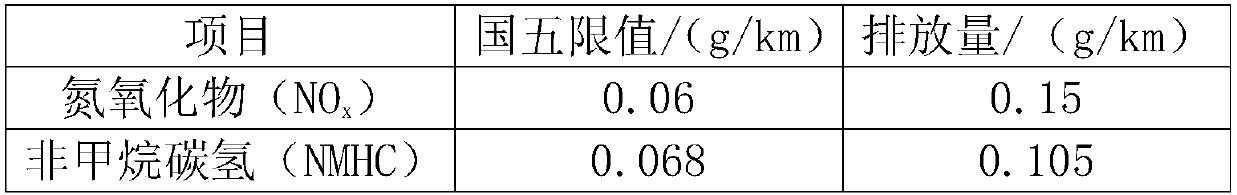

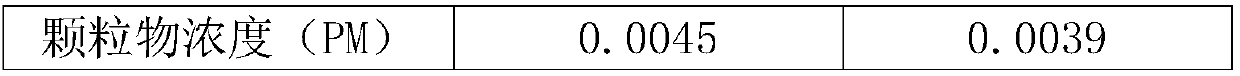

[0020] Low-sulfur biofuel, made from the following raw materials in parts by weight (just stir at 45°C for 25 minutes): 85 parts of aromatic hydrocarbons, 22 parts of glycols, 5 parts of octanol, 0.8 parts of diisobutyl ether, 2-ethyl ether 0.1 part of base hexyl nitrate, 0.08 part of dimethyl carbonate; Described aromatic hydrocarbon is the mixture of 35 parts by weight toluene, 32 parts by weight ethylbenzene and 12 parts by weight xylene; Described glycol is 20 parts by weight ethyl A mixture of glycol, 15 parts by weight propylene glycol, and 12 parts by weight butanediol. It has been determined that the biofuel in this example does not contain sulfur, has an octane number of 110, and a calorific value of 46051 kJ / kg. Sulfur content is measured according to GB 17930-2016, octane number is measured according to GBT 5487-2015, calorific value is measured according to GB 384-1981. The biofuel of this embodiment is used in gasoline vehicles, and it is detected according to GB...

Embodiment 2

[0024] Low-sulfur biofuel, made from the following raw materials in parts by weight (just stir at 45°C for 25 minutes): 95 parts of aromatic hydrocarbons, 19 parts of glycols, 7 parts of octanol, 0.5 parts of diisobutyl ether, 2-ethyl ether 0.3 part of base hexyl nitrate, 0.05 part of dimethyl carbonate; Described aromatic hydrocarbon is the mixture of 45 parts by weight toluene, 24 parts by weight ethylbenzene and 18 parts by weight xylene; Described glycol is 15 parts by weight ethyl A mixture of diol, 20 parts by weight propylene glycol and 8 parts by weight butanediol. It has been determined that the biofuel in this example does not contain sulfur, has an octane number of 111, and a calorific value of 46478 kJ / kg. Sulfur content is measured according to GB 17930-2016, octane number is measured according to GBT 5487-2015, calorific value is measured according to GB 384-1981. The biofuel of this embodiment is used in gasoline vehicles, and it is detected according to GB 176...

Embodiment 3

[0028] Low-sulfur biofuel, made from the following raw materials in parts by weight (just stir at 45°C for 25 minutes): 100 parts of aromatic hydrocarbons, 16 parts of diols, 10 parts of octanol, 0.2 parts of diisobutyl ether, 2-ethyl ether 0.6 part of base hexyl nitrate, 0.02 part of dimethyl carbonate; Described aromatic hydrocarbon is the mixture of 55 parts by weight toluene, 16 parts by weight ethylbenzene and 24 parts by weight xylene; Described glycol is 10 parts by weight ethyl A mixture of glycols, 25 parts by weight propylene glycol and 4 parts by weight butylene glycol. It has been determined that the biofuel in this example does not contain sulfur, has an octane number of 108, and a calorific value of 44897 kJ / kg. Sulfur content is measured according to GB 17930-2016, octane number is measured according to GBT5487-2015, calorific value is measured according to GB 384-1981. The biofuel of this embodiment is used in gasoline vehicles, and it is tested according to G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com