Small mark parameter self-correction method/system, readable storage medium and equipment

A self-correction and correction coefficient technology, applied in control/regulation systems, general control systems, program control in sequence/logic controllers, etc., can solve problems such as changes in equipment hardware conditions, and the inability of control mode equipment parameters to be suitable for production conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

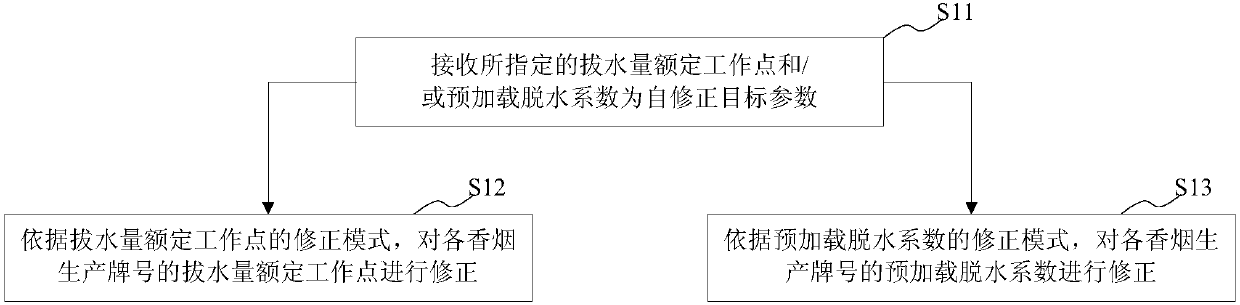

[0042] This embodiment provides a parameter self-correction method, which is used to correct the rated working point of the water removal amount and / or the preloaded dehydration coefficient in the control parameters of the dry moisture content of the shreds; the self-correction method of the parameters includes:

[0043] Accepting the specified extraction rated operating point and / or preload dehydration factor as self-correcting target parameters;

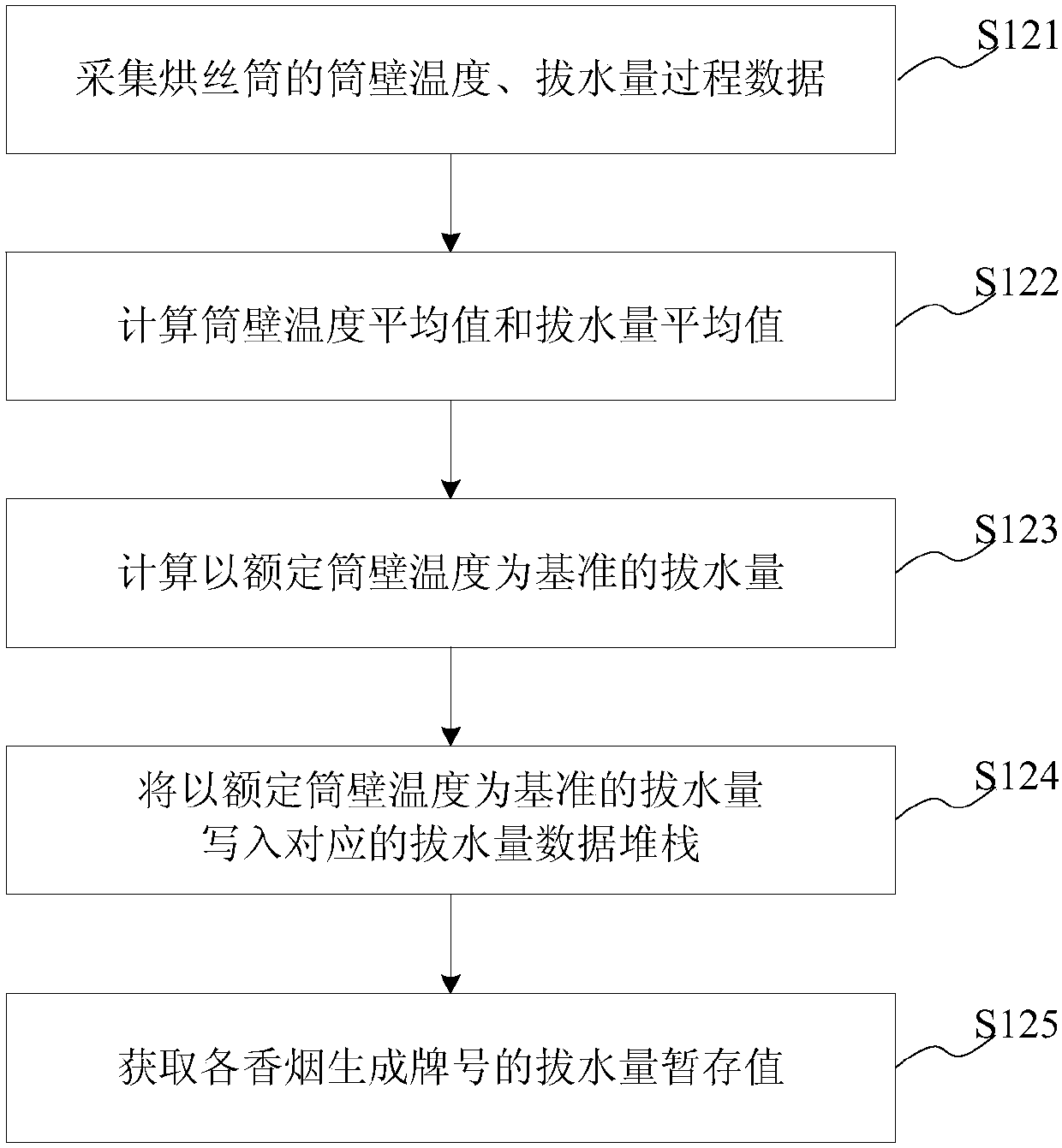

[0044] According to the correction model of the rated operating point of the water extraction capacity, the rated operating point of the water extraction capacity of each cigarette production brand is corrected; and / or

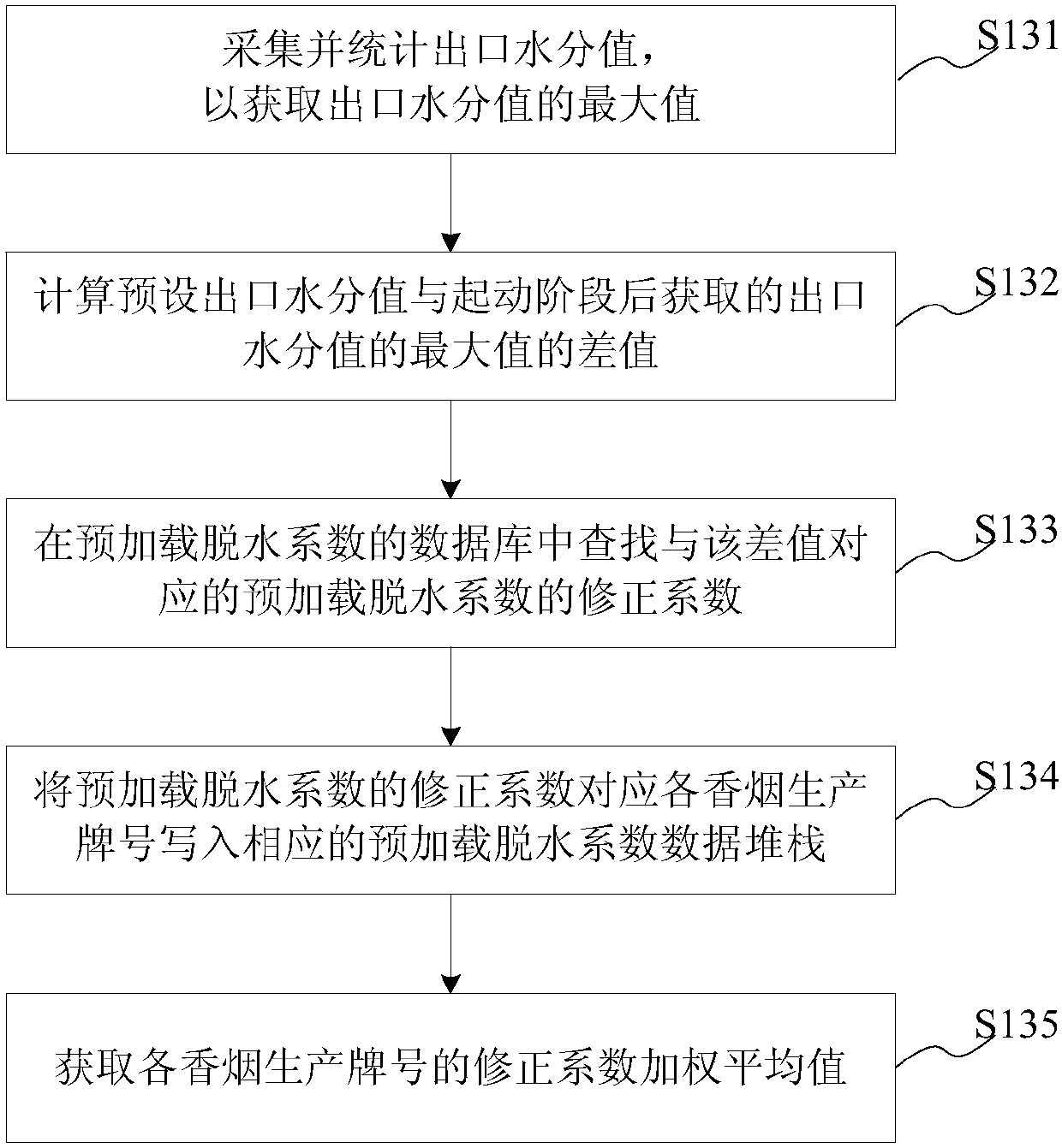

[0045] According to the correction mode of the preloaded dehydration coefficient, the preloaded dehydration coefficient of each cigarette production brand is corrected;

[0046] Wherein, the various brands of cigarettes produced include small brands and regular brands.

[0047] The method for self-correction of th...

Embodiment 2

[0138] This embodiment is a parameter self-correcting system, which is used to correct the rated working point of water extraction and / or the preloaded dehydration coefficient in the control parameters of the dry moisture content of the shreds. see image 3 , is shown as a schematic diagram of the principle of a parameter self-modifying system in an embodiment. Such as image 3 As shown, the parameter self-correction system 3 includes: a receiving module 31 , a first correction module 32 and / or a second correction module 33 .

[0139] In this embodiment, the receiving module 31 is configured to receive the designated rated operating point of water extraction and / or the preloaded dehydration coefficient as self-correction target parameters. Wherein, the various brands of cigarettes produced include small brands and regular brands.

[0140] The first correction module 32 coupled with the receiving module 32 is used for correcting the rated operating point of the water removal...

Embodiment 3

[0159] This embodiment provides a device, including: a processor, a memory, a transceiver, a communication interface, and a system bus; the memory and the communication interface are connected to the processor and the transceiver through the system bus to complete mutual communication, and the memory is used to store computer The program, the communication interface is used to communicate with other devices, the processor and the transceiver are used to run the computer program, so that the x device executes the various steps of the parameter self-correction method as described in the first embodiment, and / or executes the steps described in the first embodiment Each step of the parameter self-correction method of the small brand is described.

[0160] The system bus mentioned above may be a Peripheral Component Interconnect (PCI for short) bus or an Extended Industry Standard Architecture (EISA for short) bus or the like. The system bus can be divided into address bus, data bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com