Method for removing alachlor in water body

A technology of alachlor and water body, applied in the field of environmental treatment, can solve the problems of small adsorption capacity and low specific surface area, and achieve the effects of reducing alkalinity, large specific surface area and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

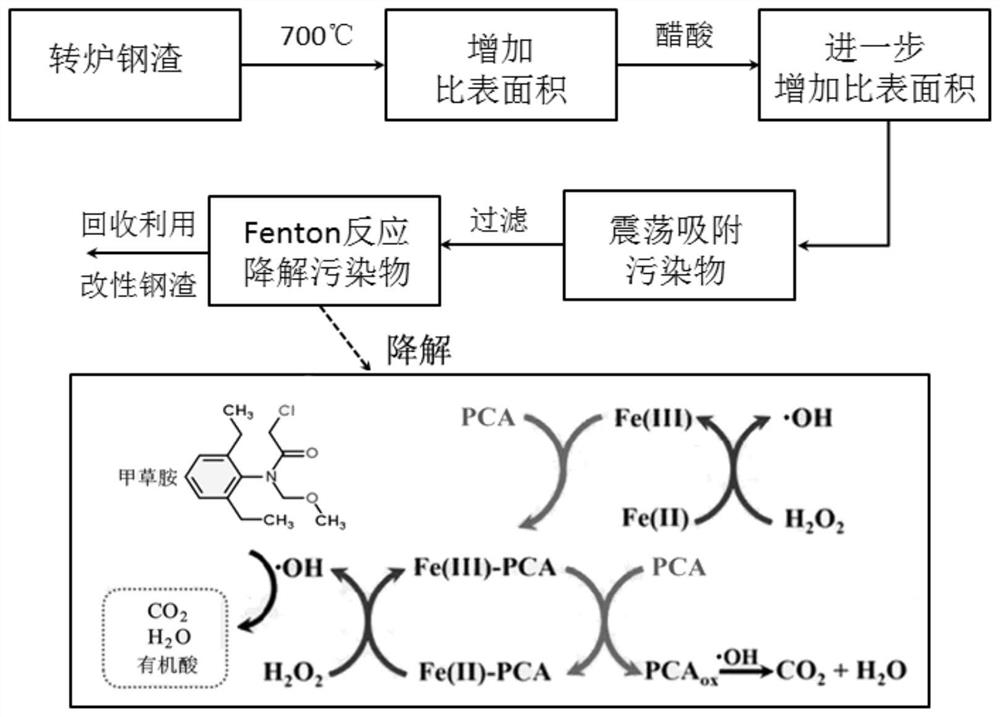

[0032] A kind of method of removing alachlor in water body of the present invention, processing flow is as figure 1 shown, including the following steps:

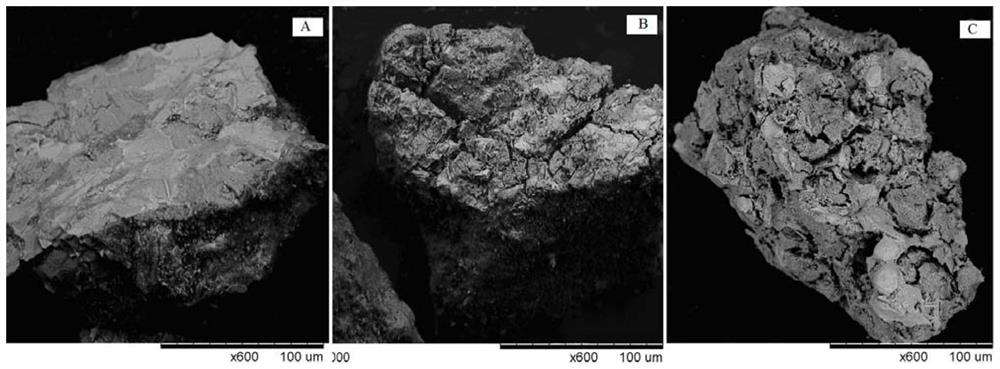

[0033](1) The converter steel slag was subjected to high temperature treatment at 700°C for 4 hours and then cooled for later use. Take 100 g of the high temperature treated converter steel slag and 1 L of acetic acid solution with a volume concentration of 5% and mix and react for 2 hours to obtain modified converter steel slag.

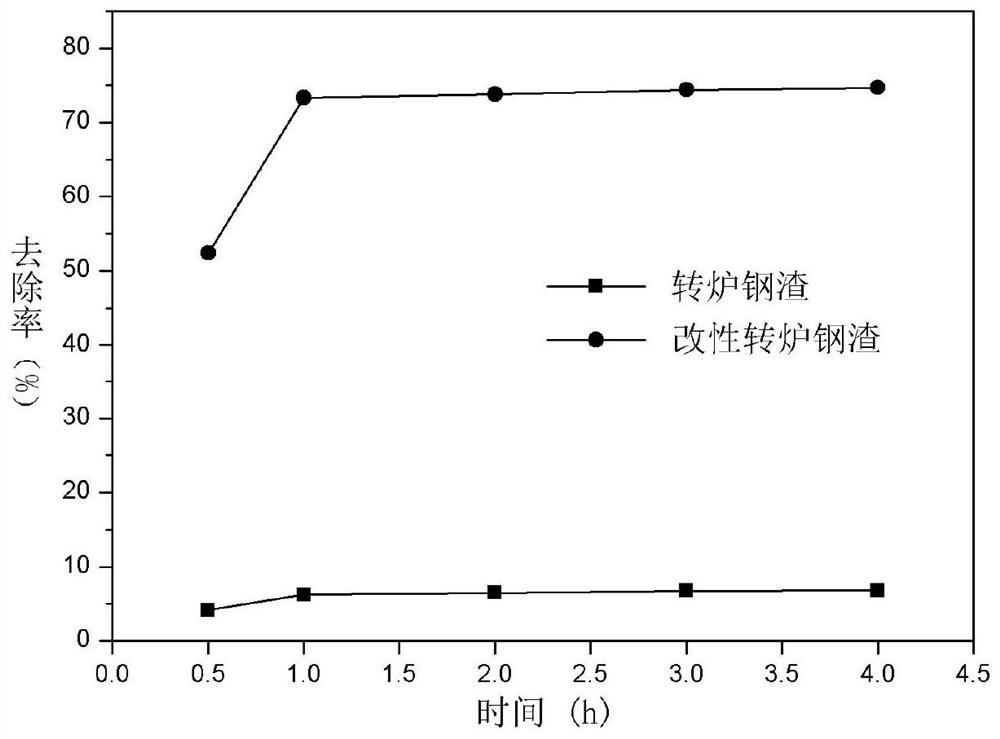

[0034] (2) Get 2 parts of alachlor solution that volume is 1L, concentration is 100mg / L, add respectively 10g unmodified converter steel slag, the modified converter steel slag in 10g step (1), carry out shock adsorption at normal temperature, Complete treatment of the alachlor solution.

[0035] Samples were taken from the system after 0.5h, 1h, 2h, 3h, and 4h of the shock adsorption reaction, and the content of alachlor in the solution was detected by high performance liquid chromatography. Th...

Embodiment 2

[0043] A kind of method of removing alachlor in water body of the present invention, processing flow is as figure 1 shown, including the following steps:

[0044] (1) Treat the converter steel slag at 700° C. for 4 hours and then cool it for later use. Take 100 g of the converter steel slag after the high temperature treatment and 1 L of acetic acid solution with a volume concentration of 5% for a shock reaction for 2 hours to obtain the modified converter steel slag.

[0045] (2) Take 6 parts of alachlor solution with a volume of 1L, the concentration is 50mg / L, 60mg / L, 70mg / L, 80mg / L, 90mg / L, 100mg / L respectively, and add 10g each to step (1) The modified converter steel slag was shaken and adsorbed at room temperature for 1 hour to complete the treatment of alachlor solution.

[0046] Sampling from the system uses high-performance liquid chromatography to detect the content of alachlor in the solution, and the measurement results are shown in Figure 4 . Figure 4 It is ...

Embodiment 3

[0048] A kind of method of removing alachlor in water body of the present invention, processing flow is as figure 1 shown, including the following steps:

[0049] (1) Treat the converter steel slag at 700° C. for 4 hours and then cool it for later use. Take 100 g of the converter steel slag after the high temperature treatment and 1 L of acetic acid solution with a volume concentration of 5% for a shock reaction for 2 hours to obtain the modified converter steel slag.

[0050] (2) Get 6 parts of alachlor solutions that have a volume of 1L and a concentration of 70mg / L, add 10g of the modified converter steel slag in step (1) respectively, carry out shock adsorption at normal temperature for 1h, and after filtering, obtain the alachlor solution adsorbed with formazan. Modified converter slag with oxalamine.

[0051] (3) The modified converter steel slag that absorbs alachlor obtained in step (2) is added to 20mL respectively, and the volume concentration is 0%, 1%, 3%, 5%, 7%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com