Epoxy resin type anchoring adhesive and preparation technology thereof

A technology of epoxy resin and planting glue, which is applied in the field of planting glue processing, can solve the problems such as the effect is not obvious, and achieve the effect of obvious use effect, sufficient bonding, and guaranteed bonding and fastening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

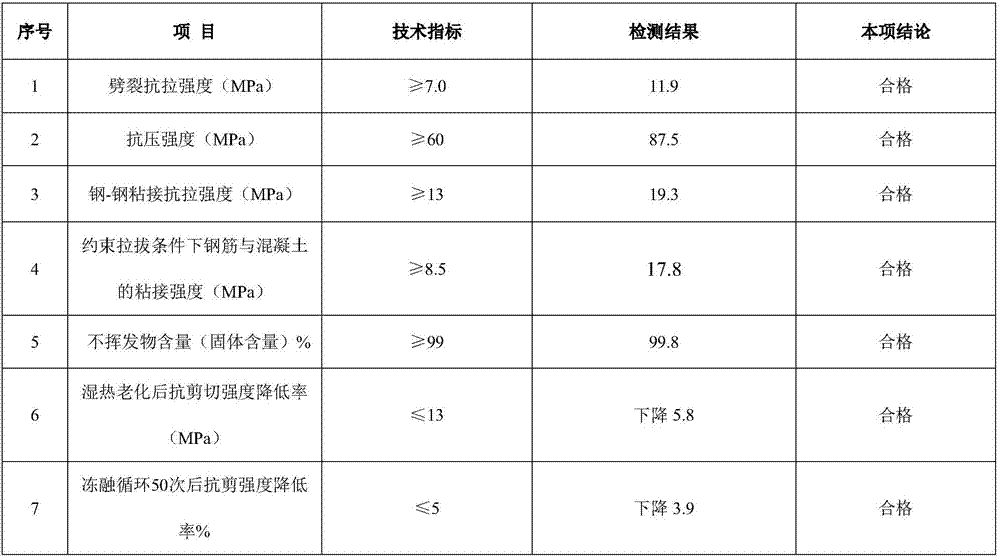

Image

Examples

Embodiment 1

[0026] An epoxy resin-type rebar-planting glue, prepared from the following raw materials:

[0027] 60kg of epoxy resin, 8kg of raw fiber powder, 2kg of fly ash, 6kg of activated diatomite, 1kg of calcium lignosulfonate, 2kg of methyl hydroxycellulose, 2kg of silicate clinker, 2kg of metakaolin powder, 2kg of heavy calcium powder , Quartz sand 3kg, expansion agent 2kg, sodium silicate solution 50kg, sodium phosphate solution 80kg;

[0028] The preparation method of activated diatomite in the above-mentioned raw materials is:

[0029] ①. Wash the diatomite raw material with water and dry it in air;

[0030] ②. Evenly sprinkle 2-3% industrial salt of the diatomite raw material on the surface of the diatomite raw material or mix it in the fuel coal;

[0031] ③. Send the diatomite raw material and fuel coal into the calcination chamber and the combustion chamber of the indirect calcination furnace respectively, and indirectly heat and calcinate the diatomite raw material. The ca...

Embodiment 2

[0041] An epoxy resin-type rebar-planting glue, prepared from the following raw materials:

[0042] 70kg of epoxy resin, 9kg of raw fiber powder, 3kg of fly ash, 7kg of activated diatomite, 2kg of calcium lignosulfonate, 3kg of methyl hydroxycellulose, 3kg of silicate clinker, 3kg of metakaolin powder, 3kg of heavy calcium powder , Quartz sand 4kg, expansion agent 3kg, sodium silicate solution 55kg, sodium phosphate solution 90kg;

[0043] The preparation method of activated diatomite in the above-mentioned raw materials is:

[0044] ①. Wash the diatomite raw material with water and dry it in air;

[0045] ②. Evenly sprinkle 3% industrial salt of diatomite raw material on the surface of diatomite raw material or mix it in fuel coal;

[0046] ③. Send the diatomite raw material and fuel coal into the calcination chamber and the combustion chamber of the indirect calcination furnace respectively, and indirectly heat and calcinate the diatomite raw material. The calcination temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com