Reconfigurable modular micro-robot and preparation method thereof

A micro-robot, modular technology, applied in the direction of micro-manipulators, manipulators, manufacturing tools, etc., can solve the problem of increasing costs, not having a multi-functional braking system, and limiting the environmental adaptability of synthetic micro-robots. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

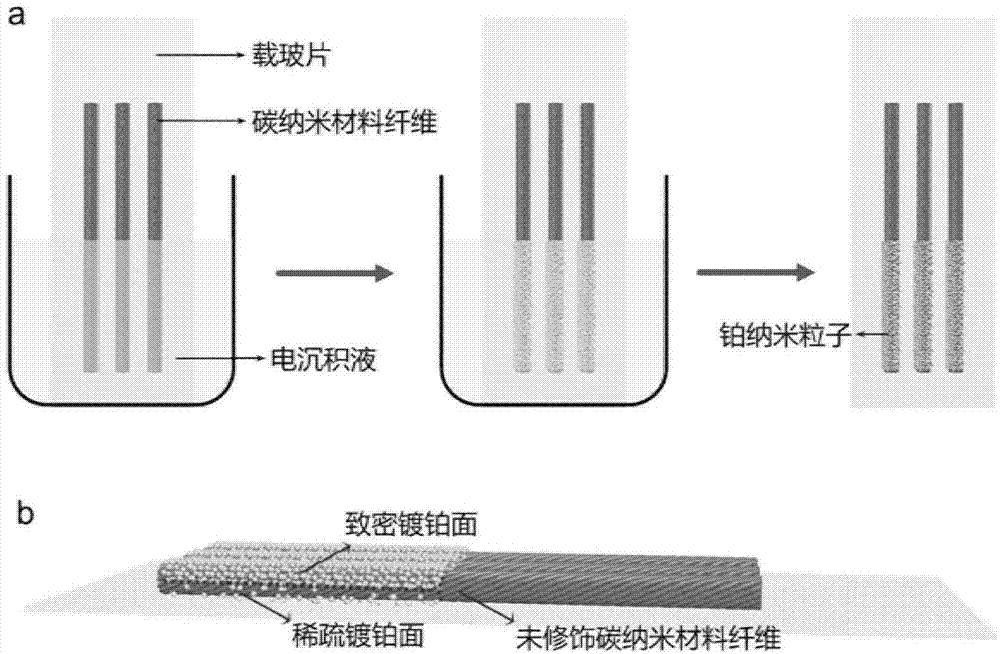

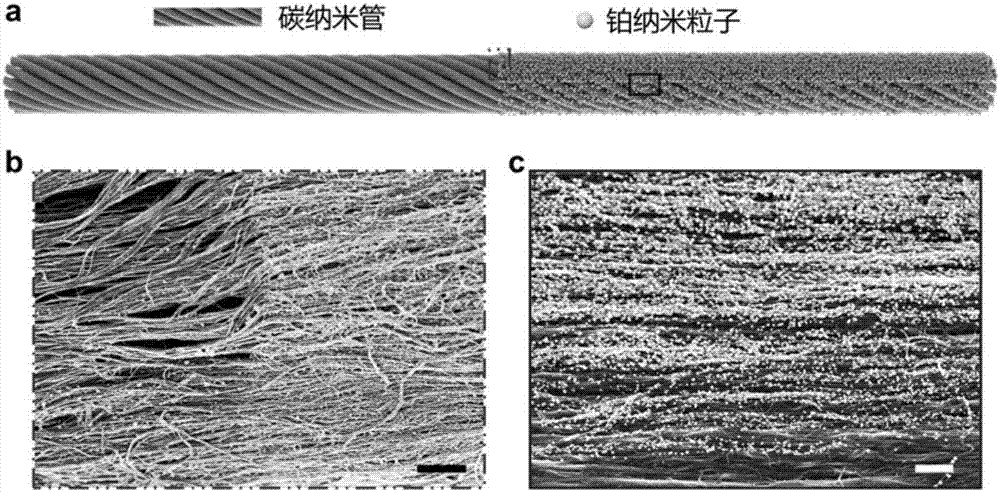

[0033] (1) Preparation of oriented carbon nanotube fibers: the oriented multi-walled carbon nanotube film is directly pulled out from the spinnable multi-walled carbon nanotube array with a width of 7 mm by a blade, and the spinning machine is used at 800 rpm Under the rotating speed, wrap it into oriented multi-walled carbon nanotube fibers, drop-coat ethanol solution along the fiber axis, and dry at room temperature for 2 hours to obtain oriented oriented multi-walled carbon nanotube fibers;

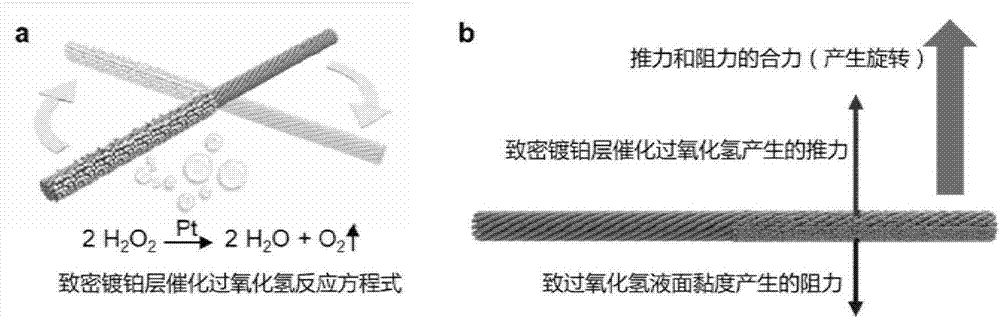

[0034] (2) Preparation of fibrous micro-robot assembly unit with asymmetric modification of platinum nanoparticles: configure an electrolyte solution containing 1 mmol per liter of potassium chloroplatinate and 0.1 mol per liter of potassium chloride, and use a three-electrode system for electrochemical deposition on Oriented multi-wall carbon nanotube fibers show off modified platinum nanoparticles; the working electrode is a carbon nanotube fiber with a diameter of 50 microns and a le...

Embodiment 2

[0037] (1) Preparation of oriented carbon nanotube fibers: the oriented multi-walled carbon nanotube film is directly pulled out from the spinnable multi-walled carbon nanotube array with a width of 8 mm by a blade, and the spinning machine is used at 950 rpm Under the rotating speed, wrap it into oriented multi-walled carbon nanotube fibers, drop-coat ethanol solution along the fiber axis, and dry at room temperature for 1 hour to obtain oriented oriented multi-walled carbon nanotube fibers;

[0038] (2) Preparation of fibrous micro-robot assembly unit with asymmetric modification of platinum nanoparticles: configure an electrolyte solution containing 1 mmol per liter of potassium chloroplatinate and 0.1 mol per liter of potassium chloride, and use a three-electrode system for electrochemical deposition on Oriented multi-walled carbon nanotube fibers show off modified platinum nanoparticles; the working electrode is a carbon nanotube fiber with a diameter of 80 microns and a l...

Embodiment 3

[0041] (1) Preparation of graphene fibers: Take 60 grams of graphene oxide powder and disperse it in 30 ml of deionized water to obtain a graphene oxide dispersion. After ultrasonic oscillation for 3 hours, heat and concentrate the dispersion to 2 ml; inject the obtained concentrate into the inner diameter After being a 70-micron polytetrafluoroethylene tube, seal its two ends, and heat it in a muffle furnace at a temperature of 200°C for 5 hours to obtain a graphene fiber;

[0042] (2) Preparation of fibrous micro-robot assembly unit with asymmetric modification of platinum nanoparticles: configure an electrolyte solution containing 1 mmol per liter of potassium chloroplatinate and 0.1 mol per liter of potassium chloride, and use a three-electrode system for electrochemical deposition on Oriented multi-walled carbon nanotube fibers show off modified platinum nanoparticles; the working electrode is a carbon nanotube fiber with a diameter of 70 microns and a length of 5 mm, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com