A kind of production method of high temperature resistant non-stick coating

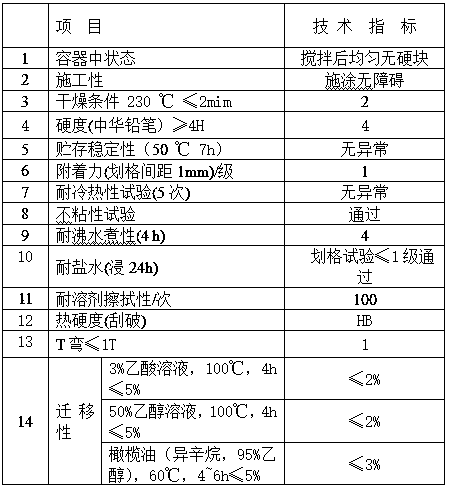

A technology of non-stick coating and production method, applied in the field of coating manufacturing, can solve the problems of unsuitability for coil coating line and sheet coating line, poor mechanical processing performance of coating film, increase production process cost, etc., so as to reduce production process flow, The effect of improving adhesion and meeting food safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 609 epoxy resin neutralization treatment: first mix 20kg of xylene, 10kg of butanol and 0.013kg of phosphoric acid and put them into the reaction pot, then put 70kg of 609 epoxy resin into the reaction pot, heat the temperature in the pot to 160-170 ℃ and wait for 609 epoxy resin After the resin is completely dissolved, start stirring, keep warm in xylene at 180°C-190°C as reflux for 2 hours, immediately cool down and discharge the material, and pack it for later use.

[0042] Mixing and dispersing: first put 35kg of the modified 609 epoxy resin liquid obtained in the above steps, 10kg of silicone resin, 3kg of phenylamino resin, 4kg of acetal amino resin, and 0.3kg of silane coupling agent into the paint mixing kettle and start stirring The speed should be controlled at 800-1000RPM.

[0043] Under the condition of stirring, add 15kg of pearlescent base material, 3.5kg of polytetrafluoroethylene powder, and 0.2kg of epoxy carbon black slurry. After feeding the materials...

Embodiment 2

[0047]609 epoxy resin neutralization treatment: first mix 20kg of xylene, 10kg of butanol and 0.013kg of phosphoric acid and put them into the reaction pot, then put 70kg of 609 epoxy resin into the reaction pot, heat the temperature in the pot to 160-170 ℃ and wait for 609 epoxy resin After the resin is completely dissolved, start stirring, keep warm in xylene at 180°C-190°C as reflux for 2 hours, immediately cool down and discharge the material, and pack it for later use.

[0048] Mixing and dispersing: first put 40kg of the modified 609 epoxy resin liquid obtained in the above steps, 10kg of silicone resin, 4kg of phenylamino resin, 5kg of acetal amino resin, and 0.5kg of silane coupling agent into the paint mixing kettle and start stirring The speed should be controlled at 800-1000RPM.

[0049] Under the condition of stirring, add 19kg of pearlescent base material, 5kg of polytetrafluoroethylene powder, and 0.5kg of epoxy carbon black slurry. After feeding the materials, i...

Embodiment 3

[0053] 609 epoxy resin neutralization treatment: first mix 20kg of xylene, 10kg of butanol and 0.013kg of phosphoric acid and put them into the reaction pot, then put 70kg of 609 epoxy resin into the reaction pot, heat the temperature in the pot to 160-170 ℃ and wait for 609 epoxy resin After the resin is completely dissolved, start stirring, keep warm in xylene at 180°C-190°C as reflux for 2 hours, immediately cool down and discharge the material, and pack it for later use.

[0054] Mixing and dispersing: first put 42kg of the modified 609 epoxy resin liquid obtained in the above steps, 12kg of silicone resin, 4.5kg of phenylamino resin, 4kg of acetal amino resin, and 0.6kg of silane coupling agent into the paint mixing kettle and start The stirring speed should be controlled at 800-1000RPM.

[0055] Under the condition of stirring, add 25kg of pearlescent base material, 6kg of polytetrafluoroethylene powder, and 0.5kg of epoxy carbon black slurry. After feeding the materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com