Later-stage compound feed capable of improving somatotype and meat quality of fattening pigs and processing method of later-stage compound feed

A technology of compound feed and fattening pigs, which is applied in the field of pig feed, can solve the problems of the body's anti-oxidation, anti-stress ability decline, breeding environment, drinking water source pollution, etc., and achieve the improvement of anti-oxidation ability, full muscle and firm texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a late-stage compound feed for fattening pigs that improves the body shape and color of the pigs, and is suitable for fattening pigs with a body weight of 60 kg to slaughter. The compound feed for fattening pigs in the late stage of improving pig body shape and flesh color is made of the following components in mass ratio: 0.2% betaine, 0.02% chromium pyridinecarboxylate, 0.01% L-selenomethionine, 0.01% vitamin E, Vitamin C 0.01%, magnesium glycine chelate 0.06%, potassium chloride 0.1%, corn 62.64%, soybean meal 22.0%, oil bran 5.0%, palm oil 0.8%, coarse bran 6.0%, calcium hydrogen phosphate 0.50%, stone powder 1.20 %, sodium chloride 0.45%, premix 1.0%.

[0027] The nutritional indicators of the late-stage compound feed for fattening pigs described in this example are: crude protein: 15.46%, calcium: 0.66%, total phosphorus: 0.52, crude fiber: 2.89%, lysine: 0.81%, digestible energy: 3294kcal / kg.

[0028] The production and processing techno...

Embodiment 2

[0040] The present embodiment provides a common fattening pig compound feed in the late stage. Compared with Example 1, the fattening pig compound feed is made of the following components in mass ratio: betaine 0.3%, chromium picolinate 0.03%, L-selenomethionine 0.02%, vitamin E 0.02%, vitamin C 0.02%, glycine chelated magnesium 0.08%, potassium chloride 0.2%, corn 62.38%, soybean meal 22.0%, oil bran 5.0%, palm oil 0.8%, crude Bran 6.0%, calcium hydrogen phosphate 0.50%, stone powder 1.20%, sodium chloride 0.45%, premix 1.0%.

[0041] The nutritional indicators of the fattening pig late stage compound feed described in this embodiment are: crude protein: 15.34%, calcium: 0.63%, total phosphorus: 0.57, crude fiber: 2.93%, lysine: 0.81%, metabolizable energy: 3006kcal / kg, Digestible energy: 3241kcal / kg.

[0042] The production and processing technology of the late-stage compound feed for fattening pigs described in this example is the same as that in Example 1.

Embodiment 3

[0044] The compound feed for fattening pigs in the late stage of improving pig body shape and flesh color is made of the following components in mass ratio: 0.4% betaine, 0.05% chromium pyridinecarboxylate, 0.02% L-selenomethionine, and 0.02% vitamin E , vitamin C 0.03%, glycine chelated magnesium 0.10%, potassium chloride 0.2%, corn 62.23%, soybean meal 22.0%, oil bran 5.0%, palm oil 0.8%, coarse bran 6.0%, calcium hydrogen phosphate 0.50%, Stone powder 1.20%, sodium chloride 0.45%, premix 1.0%.

[0045] The nutritional indicators of the fattening pig late stage compound feed described in this embodiment are: crude protein: 15.39%, calcium: 0.68%, total phosphorus: 0.51, crude fiber: 2.77%, lysine: 0.81%, metabolizable energy: 2981kcal / kg, Digestible energy: 3206kcal / kg.

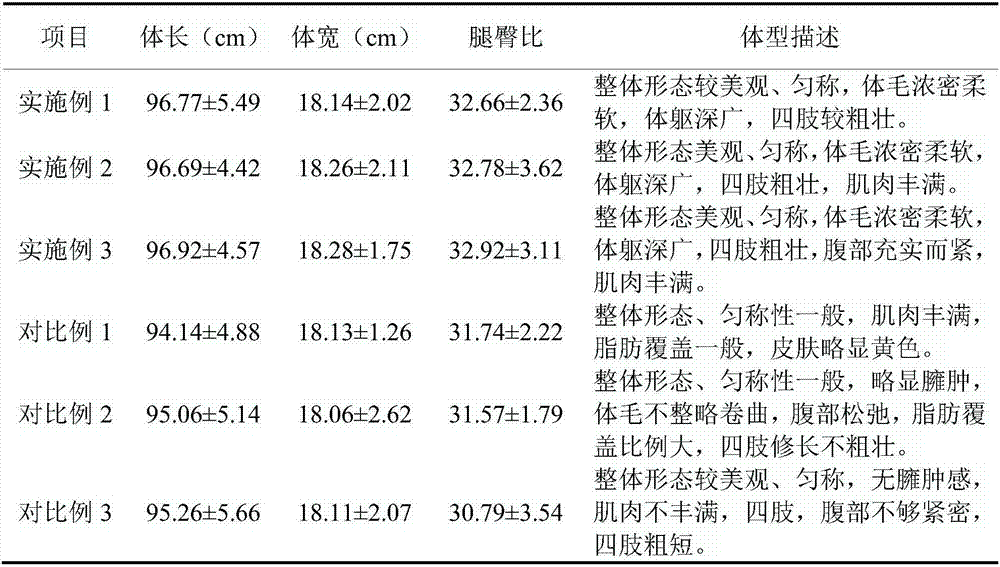

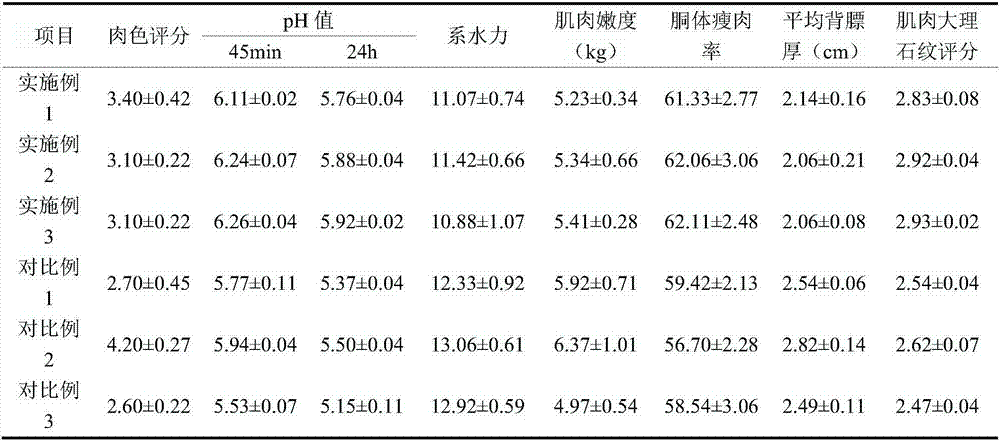

[0046] In order to specifically demonstrate the remarkable effect of the functional feed additive added in the present invention, the applicant has carried out corresponding tests and comparisons, which ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Metabolizable energy | aaaaa | aaaaa |

| Metabolizable energy | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com