Azeotropic rectification separation apparatus, azeotropic distillation separation method of n-hexanol, and applications of apparatus and method

A technology of azeotropic distillation and separation device, which is applied in the field of chemical distillation and can solve the problems of serious environmental pollution, high process energy consumption, and human hazards of benzene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

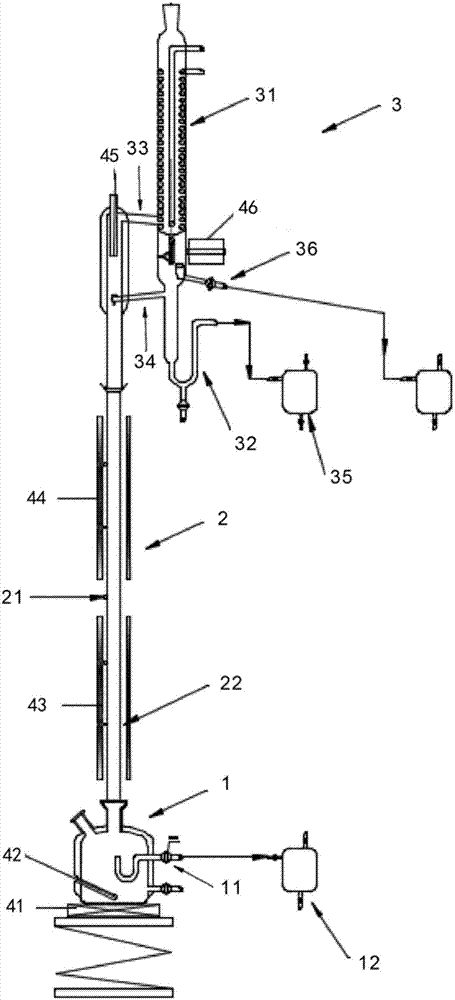

[0062] use as figure 1 The shown azeotropic rectification separation device carries out continuous azeotropic distillation of water-containing n-hexanol, and the azeotropic rectification separation device includes a tower kettle 1, a distillation tower 2, a condensation phase separation unit 3, a tower kettle heating control unit, and a reflux ratio control unit. unit and feed control unit.

[0063] Among them, the tower kettle 1 is provided with an overflow pipe 11, and the overflow pipe 11 is connected to the second product tank 12. The tower kettle 1 is made of double-layer vacuum hard glass material, and is heated by a flat-bottom electric heating method. The heating of the tower kettle 1 passes through The tower kettle heating control unit controls.

[0064] The tower body of distillation tower 2 is provided with 5 feeding ports 21 and 1 is arranged on the sampling port 22 near the tower body bottom, selects the feeding port 21 that is positioned at the middle position o...

Embodiment 2

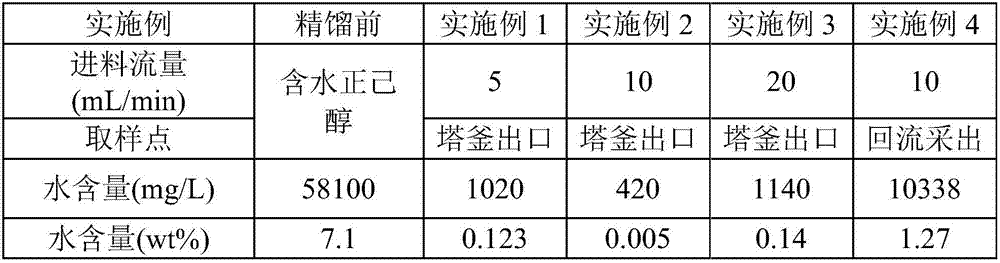

[0070] Sampling The continuous azeotropic distillation of n-hexanol containing water was carried out with the same device and method as in the examples, except that the feed flow rate was 10 mL / min.

[0071] Sampling from the second product tank 12 was started 1 hour after the feed. The water content of the samples was analyzed and the results are shown in Table 1.

Embodiment 3

[0073] Sampling The continuous azeotropic finishing of n-hexanol containing water is carried out with the same device and method as in the examples, the difference is that the feed flow rate is 20mL / min.

[0074] Sampling from the second product tank 12 was started 1 hour after the feed. The water content of the samples was analyzed and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com