Preparation method of COF/GO (covalent organic framework/graphene oxide) adsorbent and application

An adsorbent and graphene technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sewage treatment, etc., can solve the problems of small adsorption capacity and low adsorption efficiency, achieve enhanced adsorption effect, and improve adsorption performance , the effect of efficient removal method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

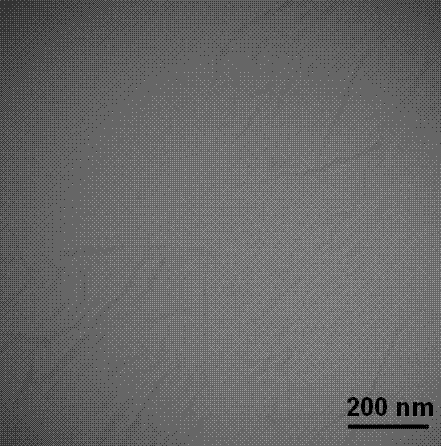

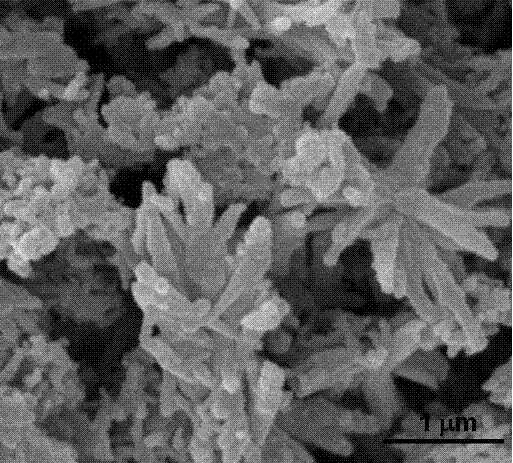

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: the preparation method of a kind of COF / GO adsorbent of this embodiment is carried out according to the following steps:

[0020] 1. The modified Hummer method was used to prepare GO: under the condition of ice-water bath, the temperature was controlled at -4~4 ℃, the graphite powder and concentrated sulfuric acid were mixed, and after mechanical stirring for 10~30 min, KMnO was slowly added to it. 4 Continue to stir for 1-2 h, maintain the temperature at 0-4 °C, then raise the temperature to 40-50 °C, stir mechanically for 60-90 min, then add distilled water dropwise to the mixture to raise the temperature to 95-98 °C , and maintained at this temperature for 10–20 min, then added distilled water for dilution, and then added 30% H 2 o 2 solution, the reaction system turned golden yellow, cooled to room temperature, washed with 5% hydrochloric acid and distilled water until neutral to obtain a GO dispersion, and vacuum dried at 40-60 °C for 12-2...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the volume ratio of the mass of GO powder described in step 1 to the mixed solution is 1mg:5mL; the others are the same as Embodiment 1.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the volume ratio of the mass of GO powder described in Step 1 to the mixed solution is 1mg:10mL; the others are the same as Embodiment 1.

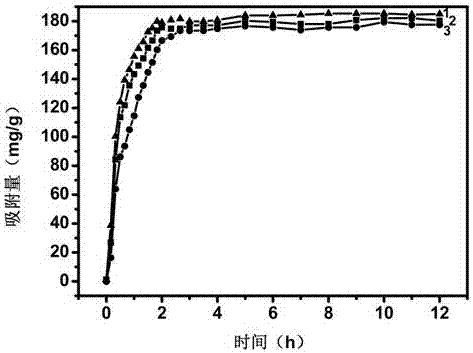

[0026] Prove the beneficial effect of the present invention by following test:

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com