Automobile exhaust gas purification device with sound attenuation function

A purification device and automobile exhaust technology, which is applied in the direction of mufflers, exhaust devices, air quality improvement, etc., can solve the problems of failing to meet the exhaust emission standards and unsatisfactory effects, and achieve reduction of exhaust emission, content reduction, and noise reduction pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

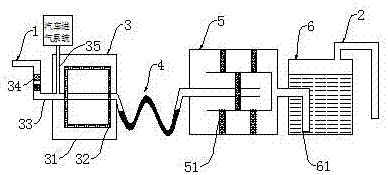

[0033] The present embodiment provides an automobile exhaust gas purifying device with sound-absorbing effect, which includes an inlet pipe 1 , an outlet pipe 2 , a muffler 3 , a reducer 4 , a three-way catalytic converter 5 and an alkaline absorber 6 . The intake pipe 1 is connected to the muffler 3 to pass the automobile exhaust gas into the automobile exhaust purification device with noise reduction function, and the outlet pipe 2 is connected to the alkaline absorber 6 to discharge harmless exhaust gas.

[0034] The muffler 3 has a shell 31, and a sound-proof cover 32 is arranged inside the shell 31, and the sound-proof cover 32 is made of sound-absorbing material. The sound-absorbing material is selected from the sound-absorbing materials in the prior art such as: glass wool, slag wool, microporous bricks and the like. Two ends of the soundproof cover 32 are respectively provided with an air delivery pipe I 33 , and the air delivery pipe I 33 is directly connected to the ...

Embodiment 2

[0040] The present embodiment provides a foamed nickel material and a preparation method thereof. The foamed nickel material can be used as the sound-absorbing material of the automobile exhaust purification device provided by the present invention. Compared with traditional sound-absorbing materials, it has light weight , The advantage of strong sound absorption effect.

[0041] The raw materials of the nickel foam material include 100 parts of nickel, 1-10 parts of copper, 0.1-1 part of zinc, 0.1-1 part of titanium, 1-10 parts of aluminum powder, 20-30 parts of aluminum nitride, and 20-30 parts of rubber powder . The nickel foam material is prepared by the following method:

[0042] Heat the rubber powder to 300-400°C to melt, then add aluminum nitride powder to it, stir evenly and cool down; put nickel, copper, titanium, aluminum and other raw materials in a high-energy ball mill for 10-20 hours to obtain the particle size It is a powder of 1-5μm; extrude all raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com