High-flux covalent organic skeleton composite membrane and preparation method thereof

A covalent organic framework, high-flux technology, applied in the field of high-flux covalent organic framework composite membrane and its preparation, can solve the problems of poor pressure resistance and tightness, low flux of nanofiltration membrane, easy pollution, etc. Simple and easy to implement, widen the application field, and the effect of high-efficiency removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In a second aspect, an embodiment of the present invention provides a method for preparing the above-mentioned composite membrane, including:

[0031] Step 101, using amino-terminated silane coupling agent or dopamine to chemically modify the surface of the porous basement membrane, so that the surface of the basement membrane has amino active groups, and then grafting small molecular organic compounds containing aldehyde groups to obtain a functionalized porous basement membrane;

[0032] Step 102, dissolving a certain amount of aldehyde group and amino small molecular organic matter in a solvent, adding a small amount of acetic acid solution with a concentration of 1-6M, stirring and ultrasonic treatment, and preparing a precursor solution of covalent organic materials; step 101 The functionalized porous base membrane is immersed in the precursor solution, and reacted at a certain temperature for 12-72 hours, so that the covalent organic framework material can fully gr...

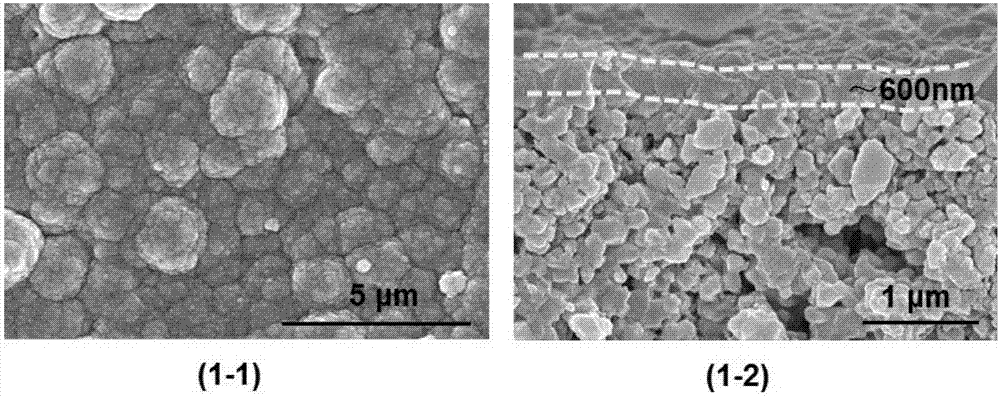

Embodiment 1

[0045] Tubular ceramics (Al 2 o 3 ) porous base membrane, the average pore size and porosity of the base membrane are 0.1 μm and 40% respectively; the base membrane is chemically modified by selecting amino-terminated silane coupling agent γ-aminopropyltriethoxysilane.

[0046] Step a, immerse the tubular ceramic basement membrane in a toluene solution of an amino-terminated silane coupling agent with a concentration of 1 mM, and react at 110° C. for 2 hours after argon protection, so that the surface of the basement membrane has an amino active group; then The aminated porous base membrane was immersed in a dioxane solution of 1,3,5-benzenetricarbaldehyde at a concentration of 3 mg / ml, and reacted at 150° C. for 1 hour to obtain a functionalized porous base membrane;

[0047] Step b, dissolve 30mg of 1,3,5-benzenetricarbaldehyde and 30mg of p-phenylenediamine in 10ml of dioxane, then add a 3M acetic acid solution with a volume of 1 / 5 of dioxane, stir and Prepare a precursor...

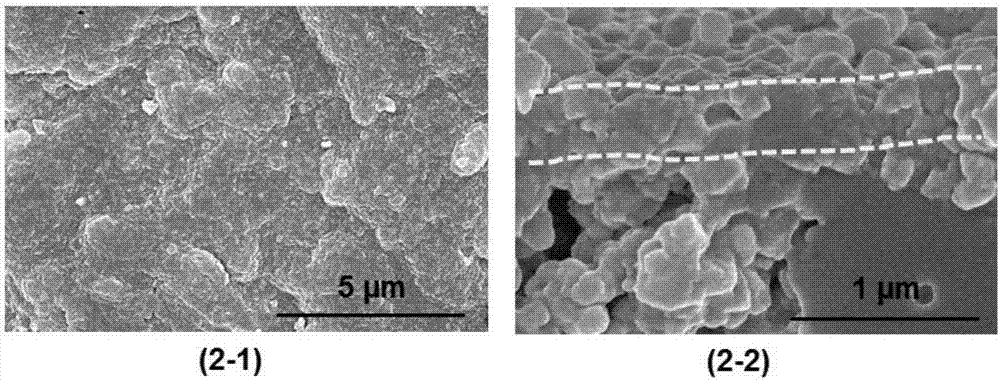

Embodiment 2

[0053] Tubular ceramics (Al 2 o 3 ) porous base membrane, the average pore size and porosity of the base membrane are 0.1 μm and 40% respectively; the base membrane is chemically modified by selecting amino-terminated silane coupling agent γ-aminopropyltriethoxysilane.

[0054] Step a, immerse the tubular ceramic basement membrane in a toluene solution of an amino-terminated silane coupling agent with a concentration of 1 mM, and react at 110° C. for 2 hours after argon protection, so that the surface of the basement membrane has an amino active group; then immersing the aminated porous base membrane in a dioxane solution of 1,3,5-benzenetricarbaldehyde at a concentration of 30 mg / 10 ml, and reacting at 25° C. for 3 hours to obtain a functionalized porous base membrane;

[0055] Step b, dissolve 30mg of 1,3,5-benzenetricarbaldehyde and 30mg of p-phenylenediamine in 10ml of dioxane, then add a 3M acetic acid solution with a volume of 1 / 5 of dioxane, stir and Prepare a precursor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com