A coupled biological treatment process for simultaneous removal of nitrogen and phosphorus from agricultural runoff

A biological treatment and runoff nitrogen technology, applied in the field of coupled biological treatment process, can solve problems such as eutrophication of lakes and reservoirs, pollution of drinking water sources, deterioration of water environment quality, etc., and achieve the reduction of effluent COD value, enhanced purification effect, and TP content Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

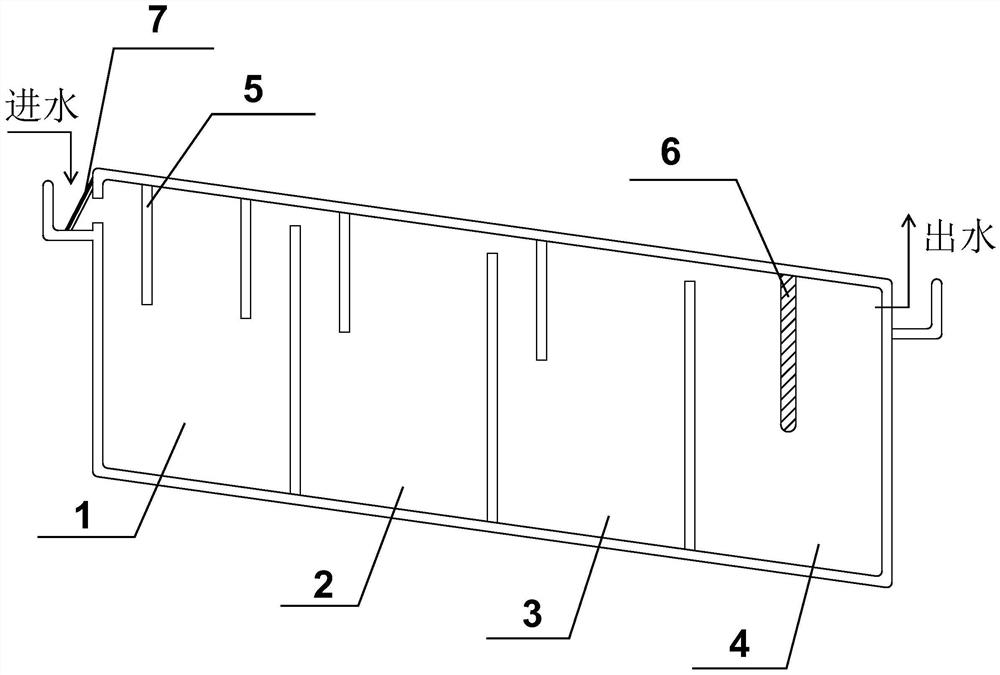

Image

Examples

Embodiment 1

[0042] The preparation process of special bio-modified filler includes the following steps:

[0043] a) Divide the citric acid into two equal parts by weight, dissolve bismuth nitrate pentahydrate and half of the citric acid in dilute nitric acid, stir evenly to form a solution A, dissolve the ammonium metavanadate and the remaining half of the citric acid in distilled water, Stir evenly to form B solution;

[0044] b) Mix A solution and B solution obtained in step a) uniformly to prepare C solution, use ammonia water to adjust the pH value of C solution to 6.2, and continue heating and stirring at 65°C until the solution turns blue to form a blue solution;

[0045] c) Add peanut shells or melon seed shells to the blue solution obtained in step 2), let stand, take out after the peanut shells or melon seed shells are fully absorbed on the surface to form a colloid, dry at 75°C for 24 hours, and then place at 500°C Calcined for 3 hours under the same conditions, and ground to o...

Embodiment 2

[0049] The preparation process of special bio-modified filler includes the following steps:

[0050] a) Divide the citric acid into two equal parts by weight, dissolve bismuth nitrate pentahydrate and half of the citric acid in dilute nitric acid, stir evenly to form a solution A, dissolve the ammonium metavanadate and the remaining half of the citric acid in distilled water, Stir evenly to form B solution;

[0051] b) Mix A solution and B solution obtained in step a) to prepare C solution evenly, use ammonia water to adjust the pH value of C solution to 6.5, and continue heating and stirring at 85°C until the solution turns blue to form a blue solution;

[0052] c) Add peanut shells or melon seed shells to the blue solution obtained in step 2), let stand, take out after the peanut shells or melon seed shells are fully absorbed on the surface to form a colloid, dry at 85°C for 48h, and then place at 550°C Calcined under conditions for 5 hours, and ground to obtain active part...

Embodiment 3

[0056] The preparation process of special bio-modified filler includes the following steps:

[0057] a) Divide the citric acid into two equal parts by weight, dissolve bismuth nitrate pentahydrate and half of the citric acid in dilute nitric acid, stir evenly to form a solution A, dissolve the ammonium metavanadate and the remaining half of the citric acid in distilled water, Stir evenly to form B solution;

[0058] b) Mix A solution and B solution obtained in step a) uniformly to prepare C solution, use ammonia water to adjust the pH value of C solution to 6.5, and continue heating and stirring at 75°C until the solution turns blue to form a blue solution;

[0059] c) Add peanut shells or melon seed shells to the blue solution obtained in step 2), let stand, take out after the peanut shells or melon seed shells are fully absorbed on the surface to form a colloid, dry at 80°C for 36h, and then place at 550°C Calcined under conditions for 5 hours, and ground to obtain active p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com