High-efficiency cycle straw anaerobic fermentation system

An anaerobic fermentation and straw technology, which is applied in the field of biogas engineering, can solve the problems of high heavy metals, blockage of biogas slurry spraying devices, and obstacles to the application and promotion of biogas slurry agriculture, and achieve the effects of convenient operation, reduction of manpower and material resources, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

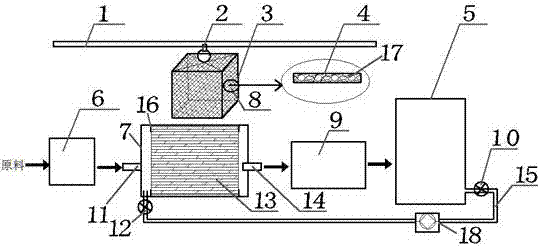

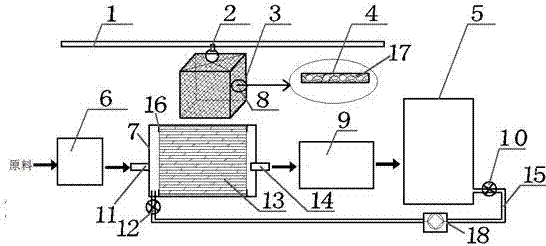

[0013] The structure of the present invention mainly includes a pretreatment workshop 6, a biogas slurry input port valve 11, a biogas slurry filtration workshop 7, a biochar filter box 3, a horizontal moving device 1, a suspended traction device 2, a filtrate output nozzle 14, and a post-treatment Workshop 9, anaerobic fermentation tank 5, biogas slurry return pipeline 15, biogas slurry output valve 10 and biogas slurry return valve 12. The straw raw material recovered from the farmland is crushed in the pretreatment workshop 6 to obtain straw with a particle size of less than 5 cm, which is loaded into the biochar filter box 3, and the biochar filter box is moved by the horizontal moving device 1 and the suspension traction device 2 3 transported to the biogas slurry filtration workshop 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com